Light source type anti-burn self-dewatering greenhouse

An anti-burn and greenhouse technology, applied in the field of agricultural greenhouses, can solve the problems of crop damage, easy generation of condensed water, and weakening of the input of light energy in greenhouses, etc., to achieve good use effects and strong pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

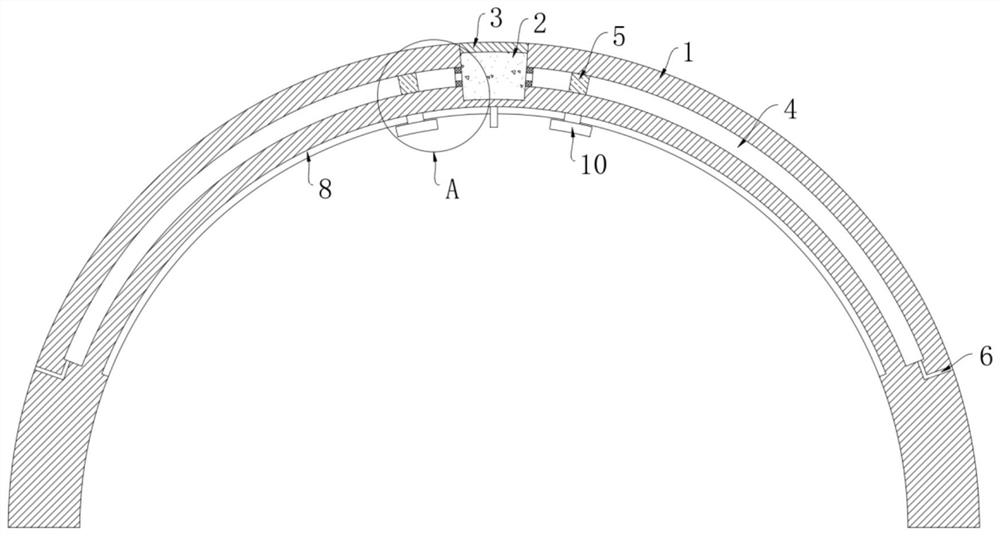

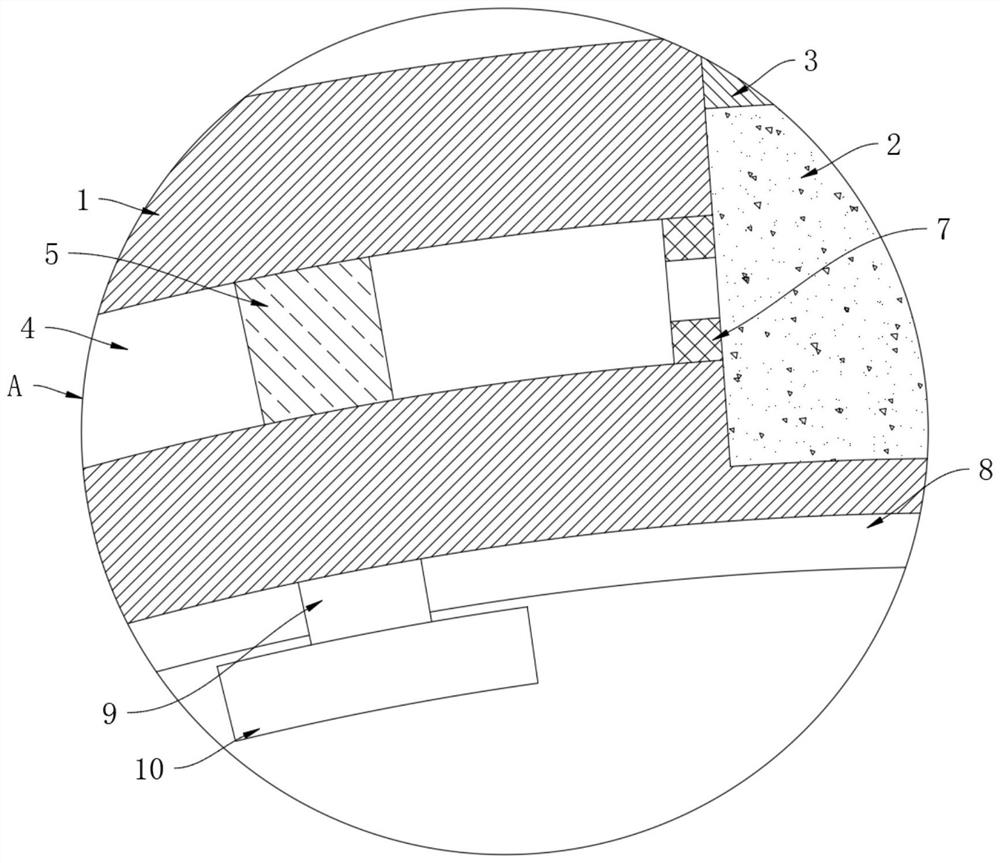

[0022] refer to Figure 1-2 , a light source type anti-burn self-water removal greenhouse, including a greenhouse body 1, a placement groove 2 is horizontally opened in the middle of the upper end surface of the greenhouse body 1, and a light-transmitting plate 3 is sealed and fixedly connected to the notch of the placement groove 2, and placed in the groove 2 A driving agent is placed, and the driving agent is a mixture of silver bromide powder and copper oxide powder, where the silver bromide powder will undergo a rapid decomposition reaction under strong light irradiation: When the light is dimmed, the silver element and bromine gas can quickly undergo the reverse reaction of the decomposition reaction of silver bromide under the catalysis of copper oxide: 2Ag+Br 2 →2AgBr, the greenhouse body 1 is symmetrically provided with arc-shaped grooves 4 communicating with the placement groove 2, and each arc-shaped groove 4 is sealed and slidably connected with a first permanent m...

Embodiment 2

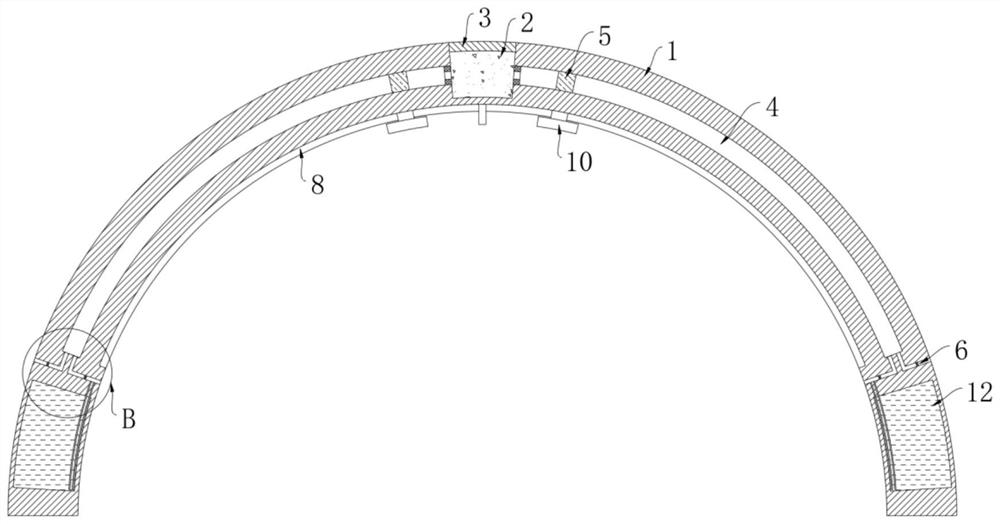

[0026] refer to Figure 3-4 The difference between this embodiment and Embodiment 1 is that: each driving area is connected with the inner wall of the greenhouse body 1 with an exhaust pipe 11, and the lower side of the greenhouse body 1 is symmetrically provided with a liquid storage tank corresponding to the exhaust pipe. 12. A plurality of capillary tubes 13 are communicated in the liquid storage tank 12, and the upper end of each capillary tube 13 is communicated with the pipe wall at the outlet of the exhaust pipe 11, and the connecting pipe 6 and the exhaust pipe 11 are respectively installed with first The one-way valve and the second one-way valve, the first one-way valve only allows outside gas or liquid to enter the driving area through the communication pipe 6, and the second one-way valve only allows the gas or liquid in the driving area to be discharged to the outside through the exhaust pipe 11 .

[0027] This embodiment can illustrate its functional principle t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com