Automatic cylinder falling system and using method thereof

An automatic doffing and doffing technology, applied in the field of chemical fiber filament production, can solve the problems of the quality of the winding wire, increase labor intensity, and low production efficiency, and achieve compact structure, low space height, and small footprint. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

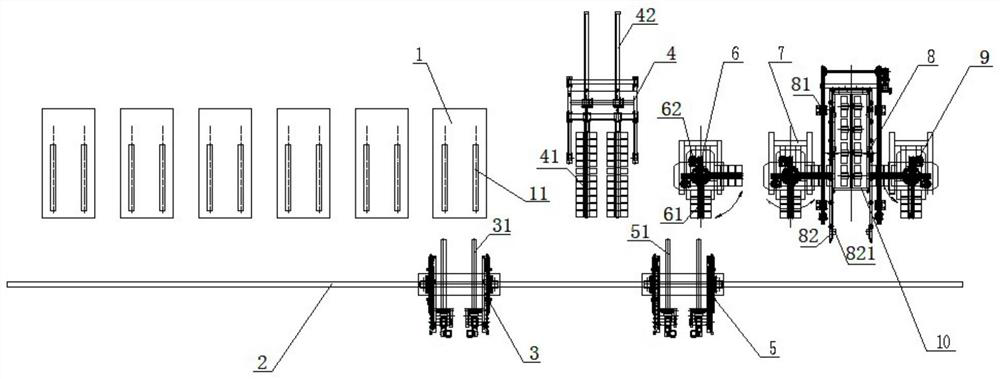

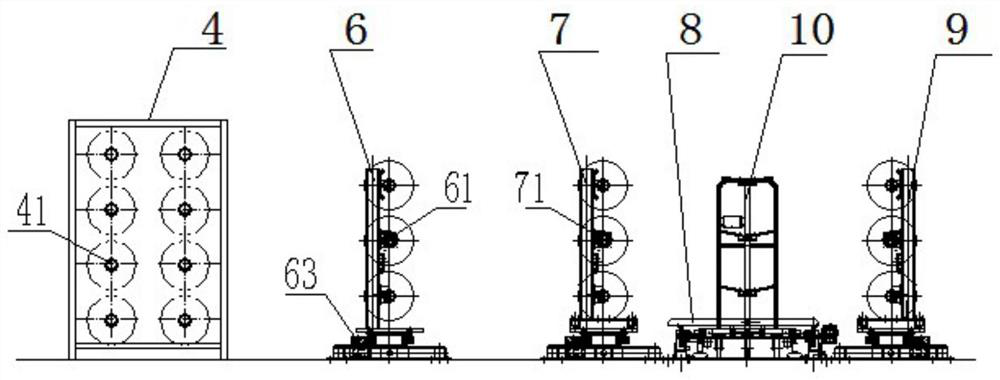

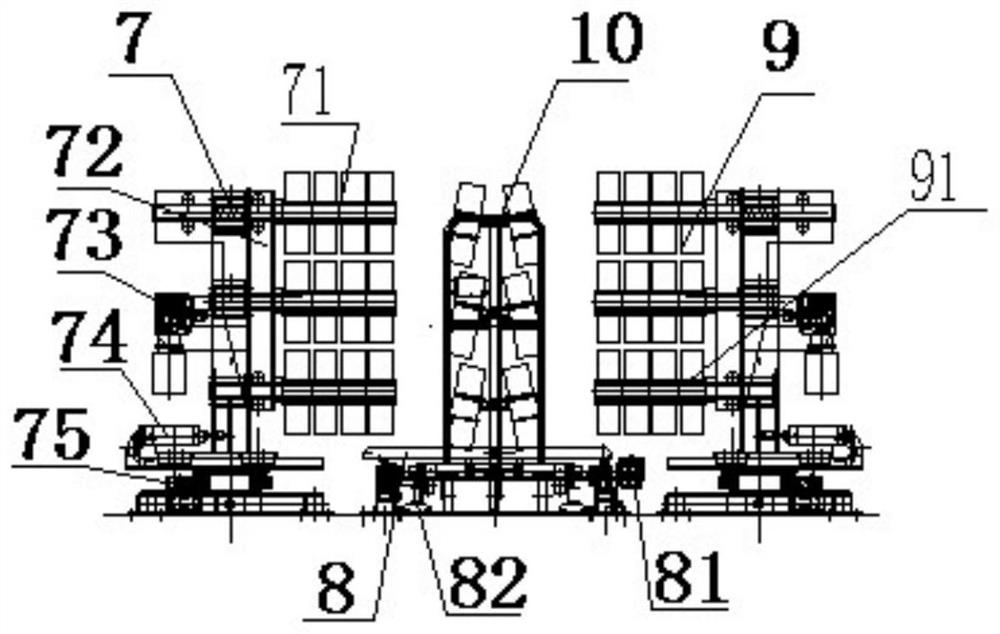

[0054] as attached figure 1 As shown, an automatic doffing system provided by an embodiment of the present invention, the automatic doffing system includes:

[0055] Winding machine 1, guide rail 2, doffing machine 3, wire storage device 4, tail wire reversing machine 6, transfer machine 5, first wire hanging machine 7, second wire hanging machine 9, wire car 10, wire car positioning and a moving device 8; the doffing machine 3 and the transfer machine 5 are all located on the guide rail 2;

[0056] The winding machine 1 is provided with a plurality of spinning positions, and each spinning position includes two spindle shafts 11, which are used to wind the tow into two-axis silk drums with opposite or identical tail filament directions;

[0057] The doffing machine 3 is used for accepting the silk bobbin delivered by the winding machine 1, and for transporting the silk bobbin to the silk storage device 4;

[0058] The silk storage device 4 is used to accept and store the mul...

Embodiment 2

[0087] An embodiment of the present invention also provides a method for using the automatic doffing system, the method comprising the following steps:

[0088] S101, the tow is wound into a filament package by the winding machine 1; the winding machine 1 is provided with a plurality of spinning positions, and each spinning position includes two spindle shafts 11, and each spinning position winds the tow into Two-axis wire drums with opposite directions for tailing;

[0089] S102, the doffing machine 3 receives the full volume signal sent by the winding machine 1, and runs along the guide rail 2 to the position of the winding machine 1 to perform the doffing operation; the doffing operation is as follows: two doffing shafts 31 of the doffing machine 3 Align the two spindle shafts 11 of the winding machine 1, the winding machine 1 transfers the bobbins to the two doffing shafts 31 of the doffing machine 3, the tails of the bobbins on the two doffing shafts 31 are in the opposit...

Embodiment 3

[0106] An embodiment of the present invention also provides a method for using the automatic doffing system, the method comprising the following steps:

[0107] S101, the tow is wound into a filament package by the winding machine 1; the winding machine 1 is provided with a plurality of spinning positions, and each spinning position includes two spindle shafts 11, and each spinning position winds the tow into Two-axis wire drums with the same tail wire direction;

[0108] S102, the doffing machine 3 receives the full volume signal sent by the winding machine 1, and runs along the guide rail 2 to the position of the winding machine 1 to perform the doffing operation; the doffing operation is as follows: two doffing shafts 31 of the doffing machine 3 Align the two spindle shafts 11 of the winding machine 1, the winding machine 1 transfers the bobbin to the two doffing shafts 31 of the doffing machine 3, the tails of the bobbins on the two doffing shafts 31 have the same directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com