Graphene multifunctional master batch adopting elastomer as carrier and preparation method thereof

A technology of graphene and elastomer, which is applied in the field of graphene multifunctional masterbatch, can solve the problems of inability to maintain electrical properties, influence of original plastic properties, and inability to process and shape, and achieve low loss rate, cost reduction, and improved electrical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

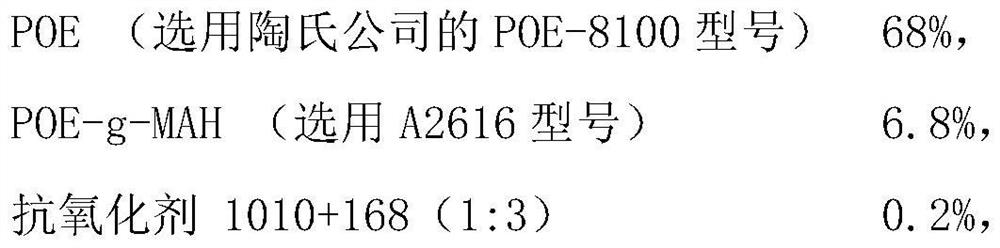

[0026] The composition ratio of the present embodiment is as follows:

[0027]

[0028]

[0029] Mix with an internal mixer at 150°C for 30 minutes, and put the mixed material into a single-screw granulator, set the temperature in four stages, 160°C, 165°C, 170°C, 165°C, and rotate at 350rpm. The masterbatch is made by cold method.

[0030] Adding 2.5% of this masterbatch to PET and spinning after melting can obtain PET fibers with 3.3% breaking strength, deodorizing and antibacterial functions. The overall performance is not only not affected, but also realizes multiple functions.

Embodiment 2

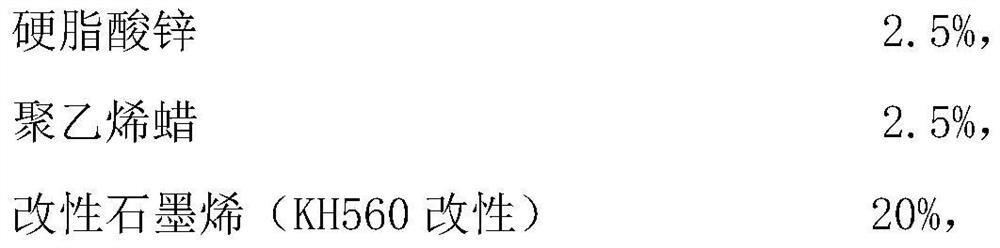

[0032] The composition ratio of the present embodiment is as follows:

[0033]

[0034] Mix with an internal mixer at 150°C for 30 minutes, and put the mixed material into a single-screw granulator, set the temperature in four stages, 160°C, 165°C, 170°C, 165°C, and rotate at 350rpm. The masterbatch is made by cold method.

[0035] Adding 5% of this masterbatch to PP, the sheet produced by extrusion or injection molding has the antistatic condition of 107Ω·m, and the overall performance is not affected.

Embodiment 3

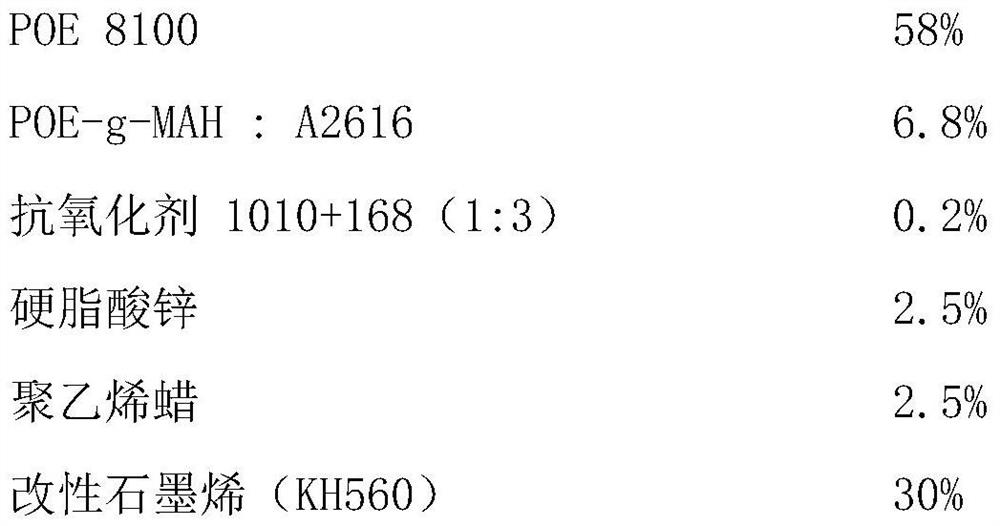

[0037] The composition ratio of the present embodiment is as follows:

[0038]

[0039] Mix with an internal mixer at 150°C for 30 minutes, and put the mixed material into a single-screw granulator, set the temperature in four stages, 160°C, 165°C, 170°C, 165°C, and rotate at 350rpm. The masterbatch is made by cold method.

[0040] Add 1.5% of this masterbatch to PE, and extrude into cables to obtain semi-insulated wire and cable sheaths, which can achieve the anti-electromagnetic field function required by ultra-high voltage cables, and the overall performance will not be affected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com