Ceramic plate binding force pull-off test method

A testing method and binding force technology, applied in the direction of measuring devices, instruments, and mechanical devices, etc., can solve the problems of non-quantitative determination of the bonding force between the substrate and the coating, poor reproducibility of test results, and cumbersome testing process, etc., to achieve easy implementation , high accuracy and simple detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

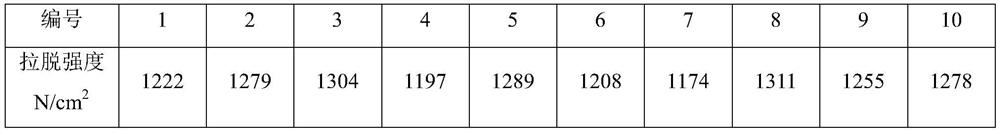

Embodiment 1

[0027]The method for testing the adhesion pull-off of the ceramic plate described in Example 1 consists of the following steps:

[0028](1) Cut squares of a certain size on the ceramic copper-plated plate, and ensure that each cut square can be cut to the ceramic substrate to obtain a ceramic copper-plated plate test sample;

[0029](2) Brush the copper layer on the other side of the ceramic copper-plated test sample with solder paste, and then press the entire surface of the ceramic copper-plated test sample with the copper foil;

[0030](3) Heat the pressed ceramic copper-plated plate test sample and copper foil at a constant temperature of 240°C. After the solder paste is melted, take the pressed ceramic copper-plated plate test sample and copper foil to lower the temperature. The ceramic copper-plated plate test sample and the copper foil are completely bonded together to prepare test sample A;

[0031](4) Place the test sample A on the tensile platform of the peeling tester and fix it;

[003...

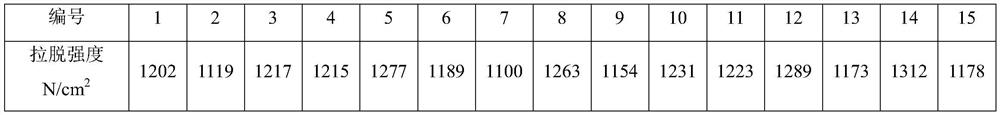

Embodiment 2

[0046]The method for testing the adhesion pull-off of the ceramic plate described in Example 2 consists of the following steps:

[0047](1) Cut squares of a certain size on the ceramic copper-plated plate, and ensure that each cut square can be cut to the ceramic substrate to obtain a ceramic copper-plated plate test sample;

[0048](2) Brush the copper layer on the other side of the ceramic copper-plated test sample with solder paste, and then press the entire surface of the ceramic copper-plated test sample with the copper foil;

[0049](3) Heat the pressed ceramic copper plate test sample and copper foil at a constant temperature at 255°C. After the solder paste is melted, take the pressed ceramic copper plate test sample and copper foil to lower the temperature. The ceramic copper-plated plate test sample and the copper foil are completely bonded together to prepare test sample A;

[0050](4) Place the test sample A on the tensile platform of the peeling tester and fix it;

[0051](5) Weld one...

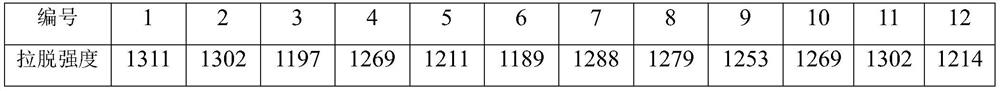

Embodiment 3

[0065]The method for testing the bonding force pull-off of the ceramic plate described in Example 3 consists of the following steps:

[0066](1) Cut squares of a certain size on the ceramic copper-plated plate, and ensure that each cut square can be cut to the ceramic substrate to obtain a ceramic copper-plated plate test sample;

[0067](2) Brush the copper layer on the other side of the ceramic copper-plated test sample with solder paste, and then press the entire surface of the ceramic copper-plated test sample with the copper foil;

[0068](3) Heat the pressed ceramic copper-plated plate test sample and copper foil at a constant temperature at 248°C. After the solder paste is melted, take the pressed ceramic copper-plated plate test sample and copper foil to lower the temperature. The ceramic copper-plated plate test sample and the copper foil are completely bonded together to prepare test sample A;

[0069](4) Place the test sample A on the tensile platform of the peeling tester and fix it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com