Composite modified electrode and preparation method and application thereof

A technology for modifying electrodes and gold electrodes, applied in the field of electrochemical analysis, can solve the problems of cumbersome detection process, complex sample processing, complex detection process, etc., and achieve the effects of high sensitivity, simple operation and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: A kind of preparation method of composite modified electrode, specifically comprises the following steps:

[0050] (1) Grinding of the gold electrode: place 0.30 μm and 0.05 μm aluminum oxide powder on the suede, wet the gold electrode with distilled water and polish the gold electrode in a vertical 8 shape, polish the electrode surface about 200 times, after wet grinding Rinse again, place the polished electrode tip vertically in a small beaker filled with a small amount of distilled water, put it into an ultrasonic cleaner to clean the working electrode for five minutes, then take it out and rinse it with distilled water to obtain a bare gold electrode with a clean surface.

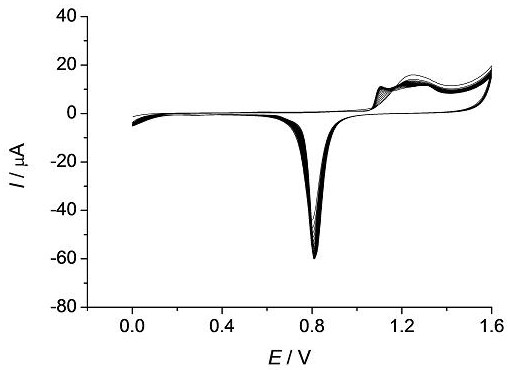

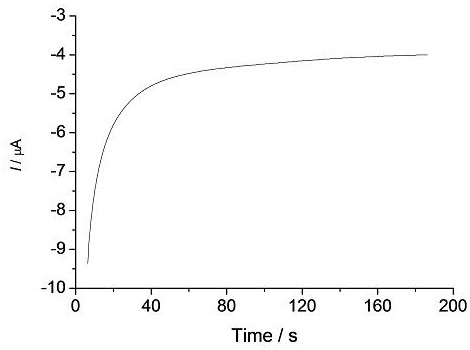

[0051] The prepared working electrode was immersed in 0.1mol / L dilute sulfuric acid solution, and the surface of the working electrode was electrochemically polished and characterized by cyclic voltammetry. The scanning range was 0-1.6V and the scanning speed was 0.1V / s. Cycle 20 Ci...

Embodiment 2

[0059] Embodiment 2: each step characterization diagram in embodiment 1:

[0060] 1) Characterization of bare electrode in sulfuric acid solution

[0061] figure 1 The process diagram of electrochemical grinding of gold electrode after alumina powder grinding and ultrasonic cleaning in 0.1mol / L dilute sulfuric acid, figure 1 Three oxidation peaks and one large reduction peak appeared in [55] . At about 0.9V, the first oxidation peak appeared, and then two consecutively appeared, and when it cycled to about 0.8V, a large reduction peak began to appear, and then returned to the starting point. This is a cycle, with such The cycle repeats 20 times. from figure 1 It can be seen that the reduction peak after grinding is −60 μA, which is much lower than −40 μA, indicating that the grinding effect of the gold electrode is good, and the following experiments can be continued on the basis of this electrode grinding. However, if the reduction peak cannot be lower than −25 μA or ar...

Embodiment 3

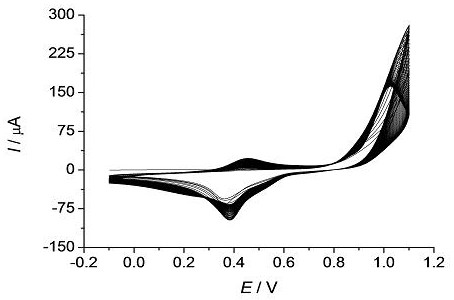

[0068] Example 3: Factors such as coating sequence, deposition potential, deposition time, scanning rate, and number of scanning circles all have varying degrees of influence on the detection sensitivity of aluminum ions.

[0069] Taking aluminum ions as an example, the optimal parameters of the above-mentioned modified electrodes are experimentally demonstrated:

[0070] Preparation of buffer solution (HAc-NaAc): Prepare 0.1mol / L sodium acetate and acetic acid solution, mix well and use a pH meter to obtain the required pH.

[0071] Preparation of aluminum standard solution: weigh 0.2414gAlCl 3 •6H 2 O was put into a volumetric flask, dissolved in buffer solution and adjusted to 100mL to obtain 10 -2 mol / L aluminum chloride solution should be diluted step by step when used.

[0072] 1) The effect of coating sequence on the detection of aluminum ions by the modified electrode:

[0073] According to the experimental procedure of Example 1, the electrodes were first manually...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com