Method for preparing carbon nanostructure comprising molybdenum disulfide, lithium secondary battery cathode comprising carbon nanostructure comprising molybdenum disulfide, prepared thereby, and lithium secondary battery comprising same

A carbon nanostructure, lithium secondary battery technology, applied in secondary batteries, nanocarbons, molybdenum sulfide, etc., can solve problems such as complex methods, and achieve the effects of improving stability, suppressing side reactions, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

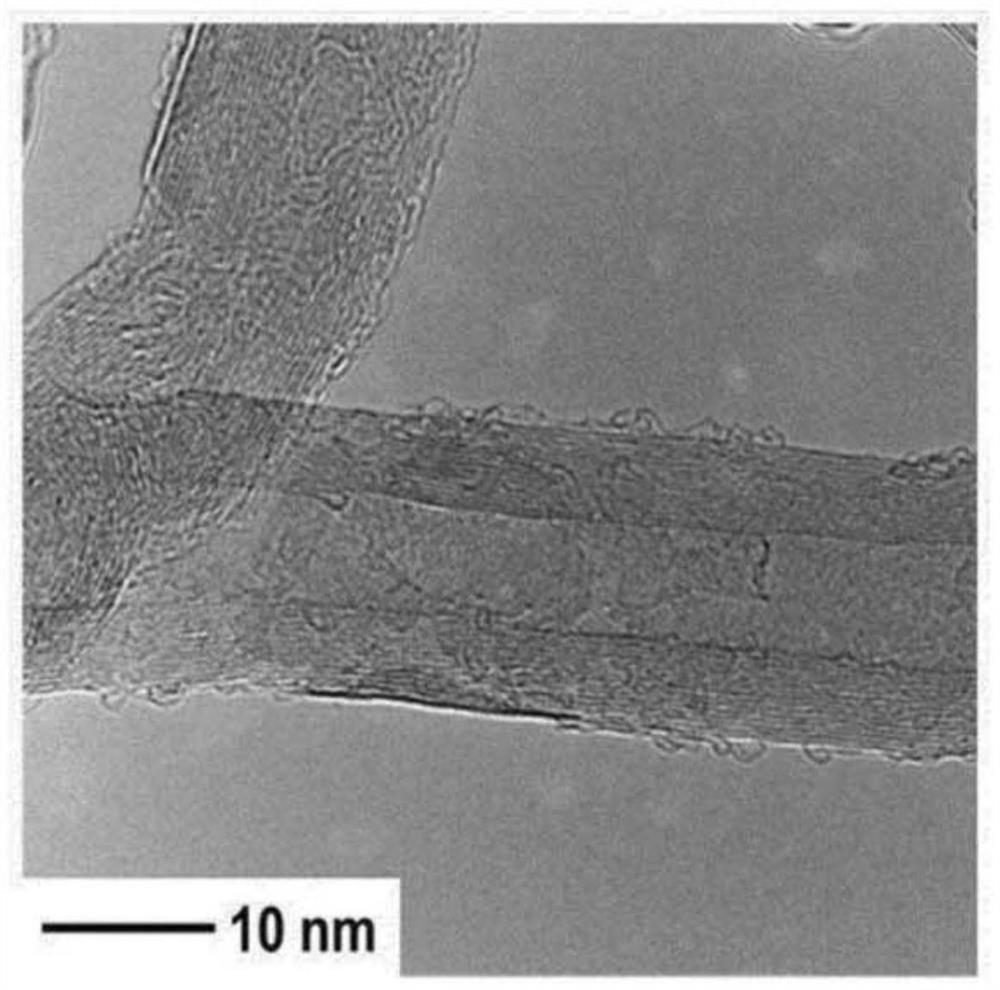

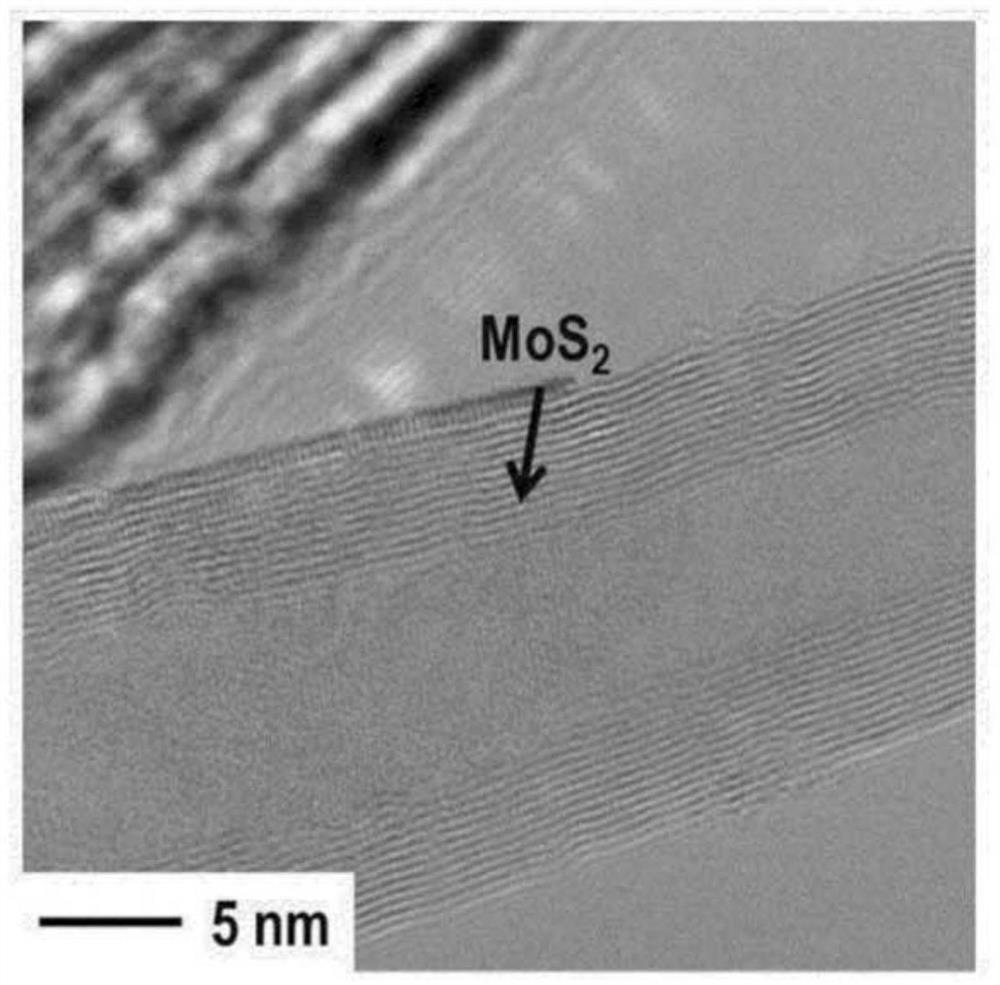

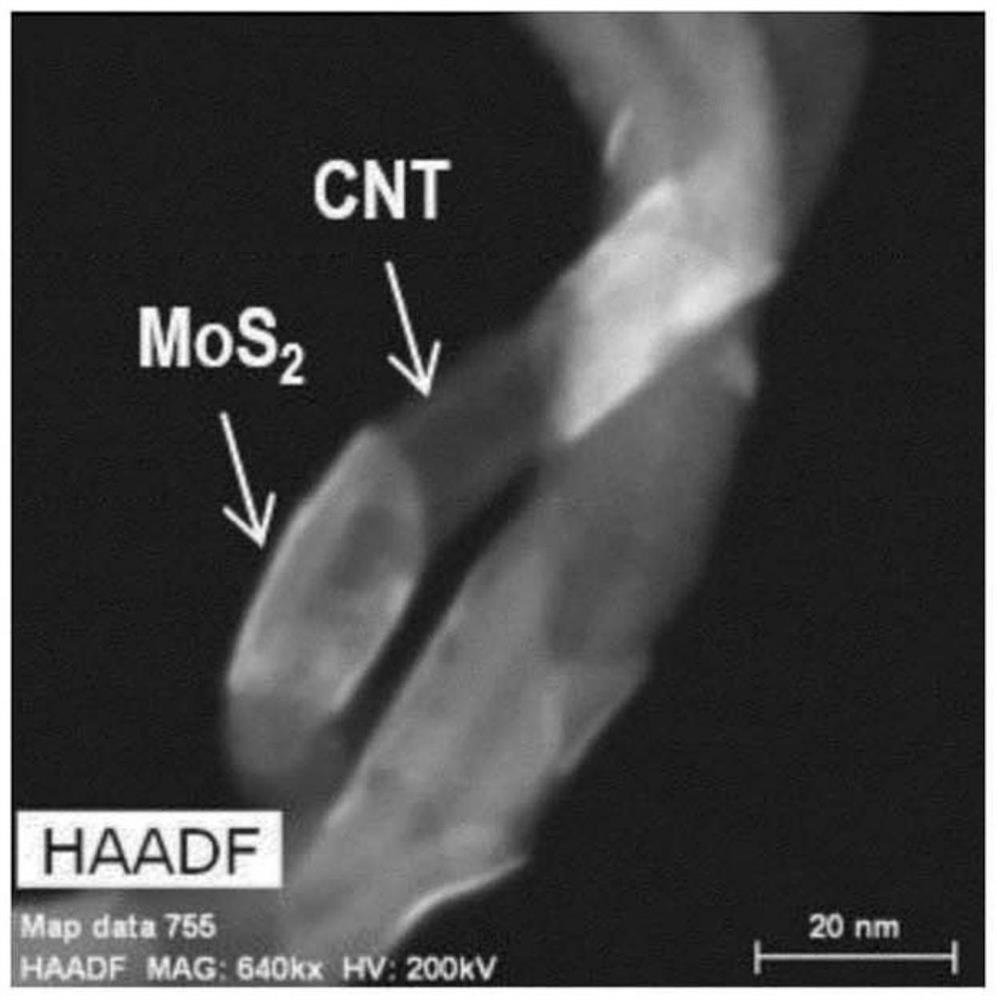

[0052] Method for preparing carbon nanostructures comprising molybdenum disulfide

[0053] The method for preparing a carbon nanostructure comprising molybdenum disulfide may include the following steps: (1) preparing a mixed solution by adding the carbon nanostructure to a solution containing a molybdenum precursor; (2) drying the mixed solution to removing the solvent and then mixing the resultant with sulfur to melt-diffuse; and (3) heat-treating the melt-diffused mixture from step (2).

[0054] An aqueous solution may be prepared by dissolving a molybdenum precursor in an aqueous solvent, and preferably, the molybdenum precursor may be dissolved in deionized water (DIW) and then used.

[0055] Molybdenum precursors according to the present invention are those capable of reacting with sulfur to form molybdenum disulfide (MoS 2 ) material, and preferably ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O). Although molybdenum precursors are diverse in their types, when ...

Embodiment 1

[0122] Example 1: Preparation of carbon nanostructures containing molybdenum disulfide

[0123] As a molybdenum precursor solution, 0.4 g of ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) (Junsei Chemical Co.) was dissolved in deionized water (DIW) to prepare an 8.1 mM aqueous solution. Subsequently, 2 g of carbon nanotubes (CNTs) were added to a solution of polyvinylpyrrolidone (PVP, Zhangzhou Huafu Chemical Co., Ltd.) as a dispersant to prepare carbon nanotubes coated with PVP on the surface. The PVP-coated CNTs were added to the above aqueous solution of ammonium molybdate, followed by mortar mixing for 10 minutes (or hours).

[0124] The mixed solution was dried in a convection oven at 80° C. for 6 hours to completely evaporate the solvent and thereby obtain a black dry powder. 2.6 g of this dry powder and 0.6 g of sulfur (Mo:S=1:8 molar ratio) were mortar mixed for 10 minutes (or hours). Afterwards, the sulfur mixture was melt-diffused in a convection oven at 15...

Embodiment 2

[0126] Example 2: Preparation of carbon nanostructures containing molybdenum disulfide

[0127] Except adding the aqueous solution of the molybdenum precursor of 19.1mM and the sulfur of 1.4g so that the molybdenum disulfide based on the total product is 30% by weight on the surface, prepared in the same manner as in Example 1 Carbon nanotubes of molybdenum disulfide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com