Mixing unloader for feed production

A technology of unloading machine and feed, which is applied in the direction of mixer, mixer accessories, dissolving, etc. It can solve the problems of poor use effect and poor palatability of feed, and achieve the effect of preventing feed from accumulating on the screen and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

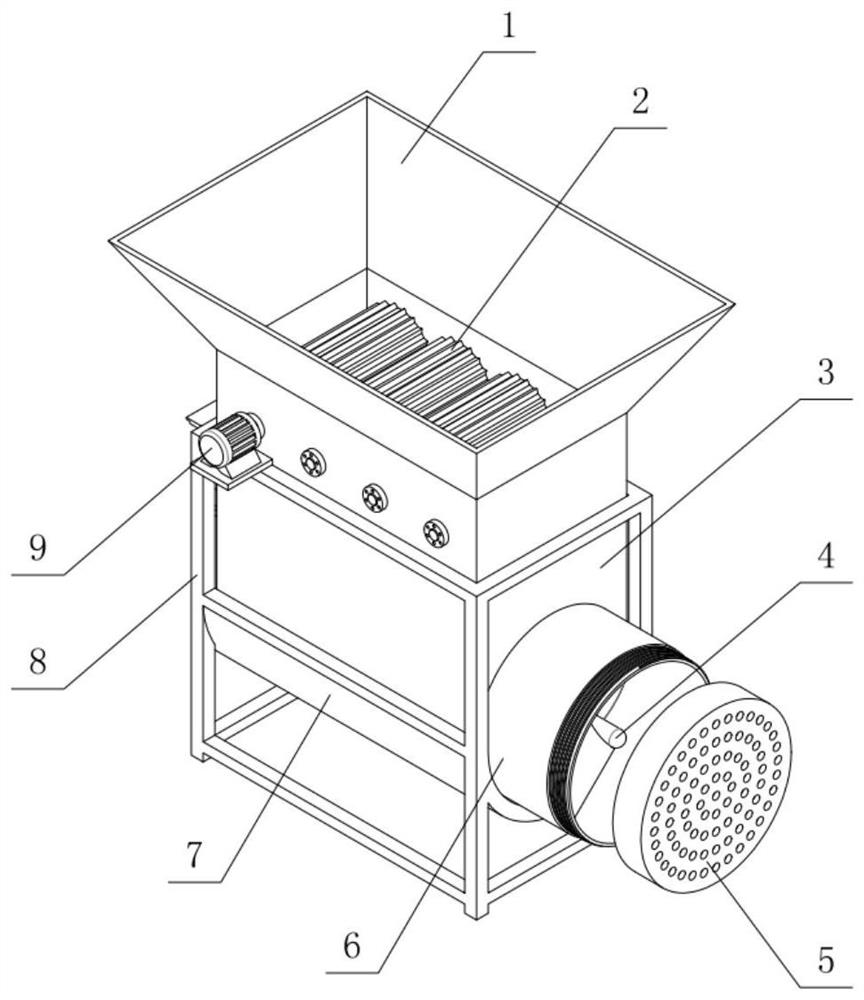

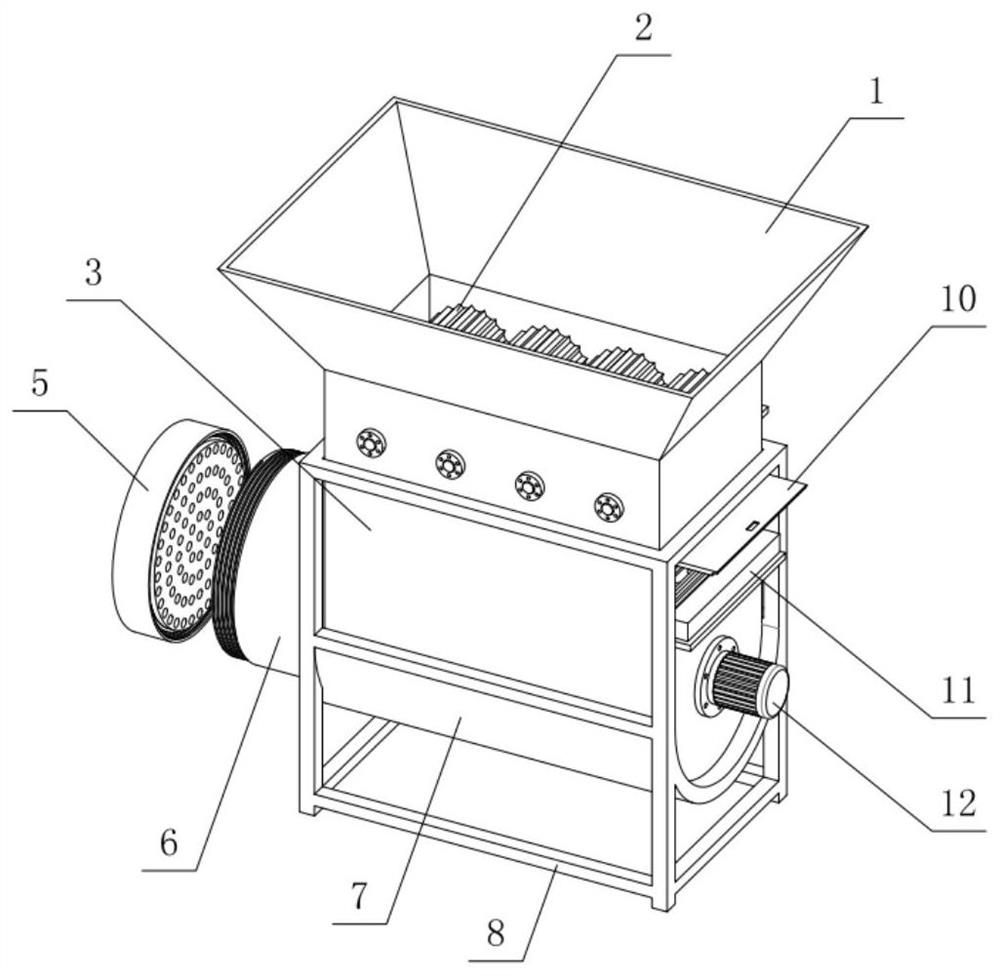

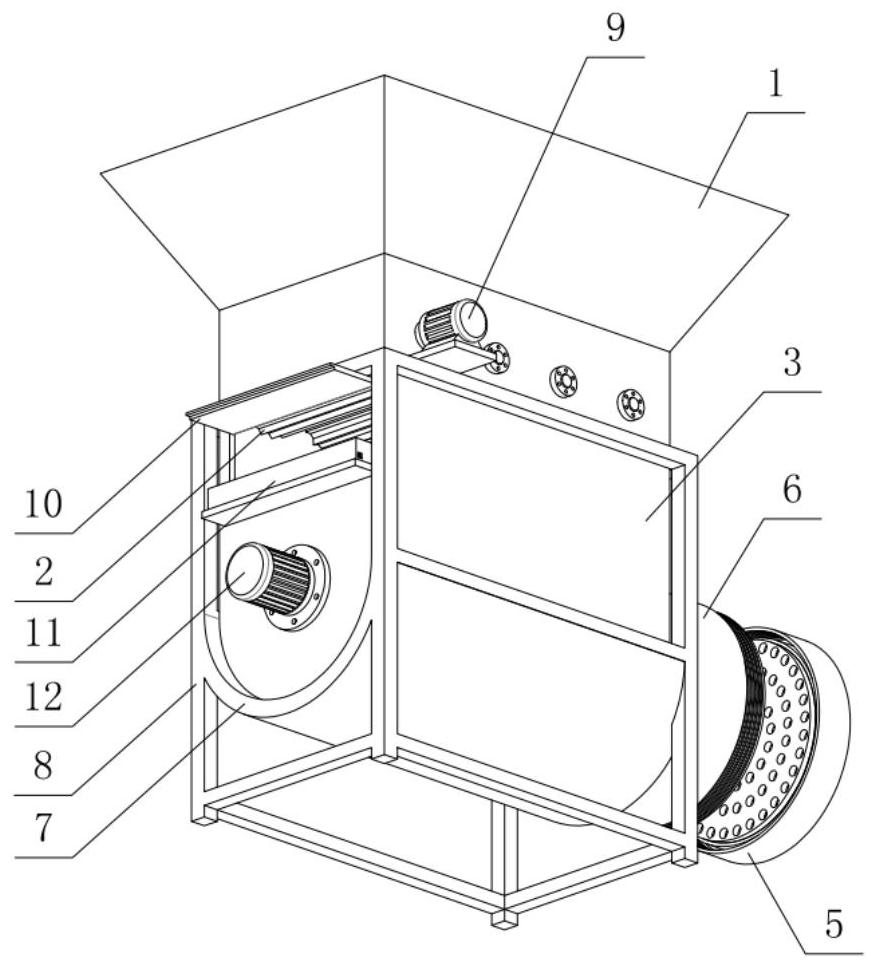

[0031] Such as Figure 1-4 The shown mixing unloader for feed production includes a support frame 8, a support plate 7 is fixedly arranged at the bottom of the support frame 8, a mixing bucket 6 is fixedly placed on the support plate 7, and the inside of the mixing bucket 6 is rotated There is a stirring and feeding mechanism, one end of the mixing barrel 6 is fixedly equipped with a discharge assembly, the top of the other end of the mixing barrel 6 is welded and fixed with a cleaning box 3, and the inside of the cleaning box 3 is fixed with a screening assembly by bolts, and the cleaning box 3 A hopper 1 is fixedly installed by welding at the top, and a crushing assembly is installed at the middle and lower parts of the hopper 1 rotatably. The top of the support frame 8 is fixedly arranged on the bottom side wall of the hopper 1 by adjusting bolts.

[0032] The crushing assembly includes several meshing crushing rollers 2, one end of the crushing roller 2 is fixedly connecte...

Embodiment 2

[0042] Such as Figure 5-6 As shown, the difference between the embodiment 2 and the embodiment 1 is: the side wall between the mixing drum 6 and the cleaning box 3 is provided with an additive injection port 15 and a temperature control box 16, and the additive injection port 15 is used to realize the injection of the additive and the cleaning of the mixing tank. The additive injection port 15 can be selected as an atomizing nozzle, so as to realize the uniform spraying of the diluted additive or cleaning water. The temperature control box 16 is used to realize the cleaning The temperature adjustment in the selection box 3 and the mixing bucket 6 is convenient to further improve the use effect of the feed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com