Cylindrical part rolling and liquid-filling deep-drawing forming device and method

A technology of liquid-filled deep drawing and cylindrical parts, which is applied in the field of metal processing, can solve the problems of easy cracking and wall thickness of cylindrical parts, low manufacturing precision of cylindrical parts, easy instability and wrinkling of flange area, etc., and achieves a solution The effect of low drawing limit, increasing forming limit, changing stress and strain state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

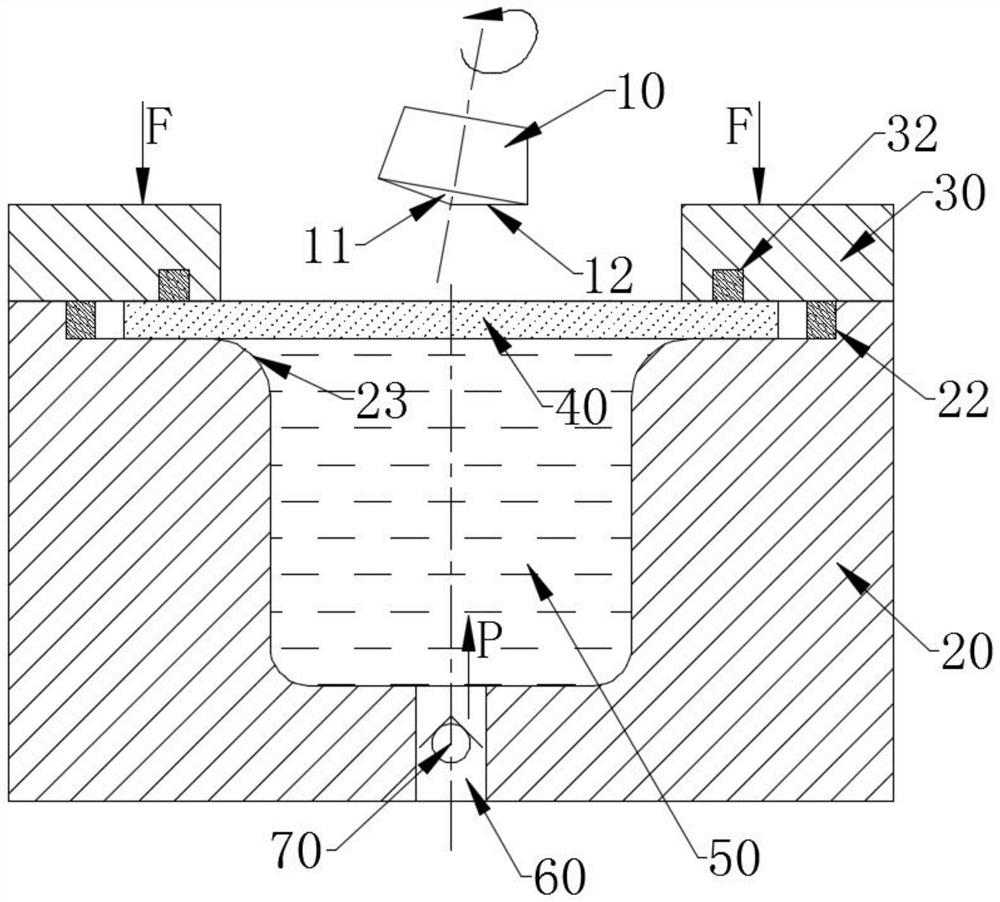

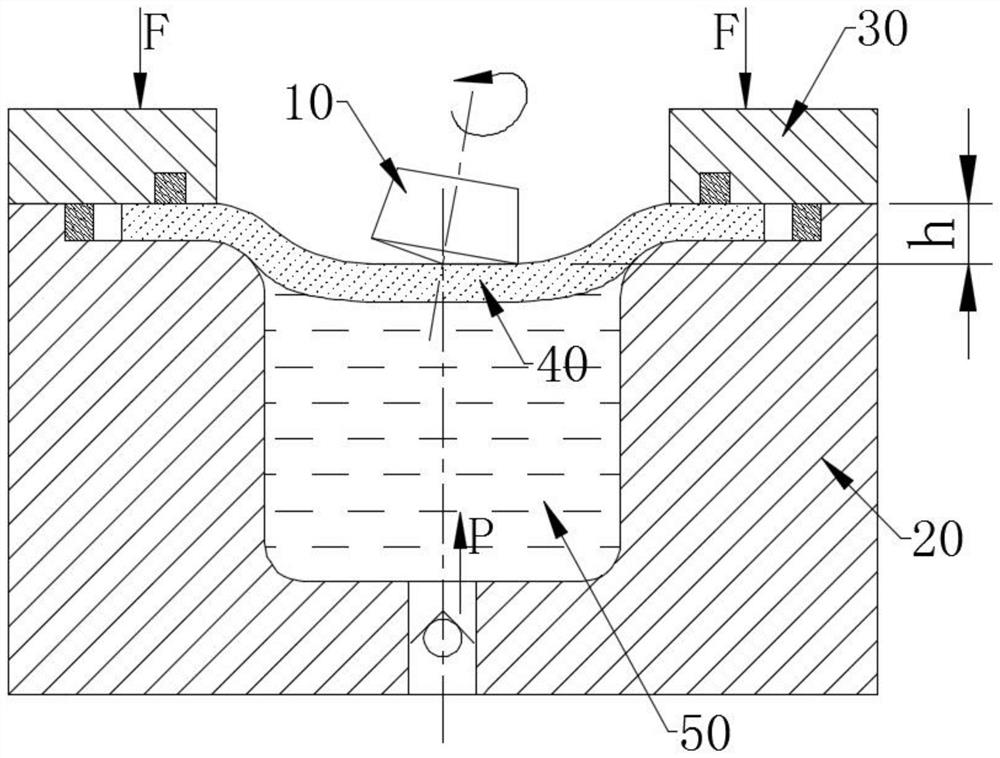

[0047] In order to solve the deficiencies and defects existing in the prior art, the present invention provides a device and method for rolling and filling liquid-filled deep-drawing of cylindrical parts, which applies partial deep-drawing to the sheet material by swinging the rolling punch, and then completes the overall drawing of the part. deep. During the deep drawing process, the liquid pressure is applied on the other side of the sheet to improve the stress state of the sheet, which can effectively improve the forming limit of the sheet and the forming quality of the parts, and save costs.

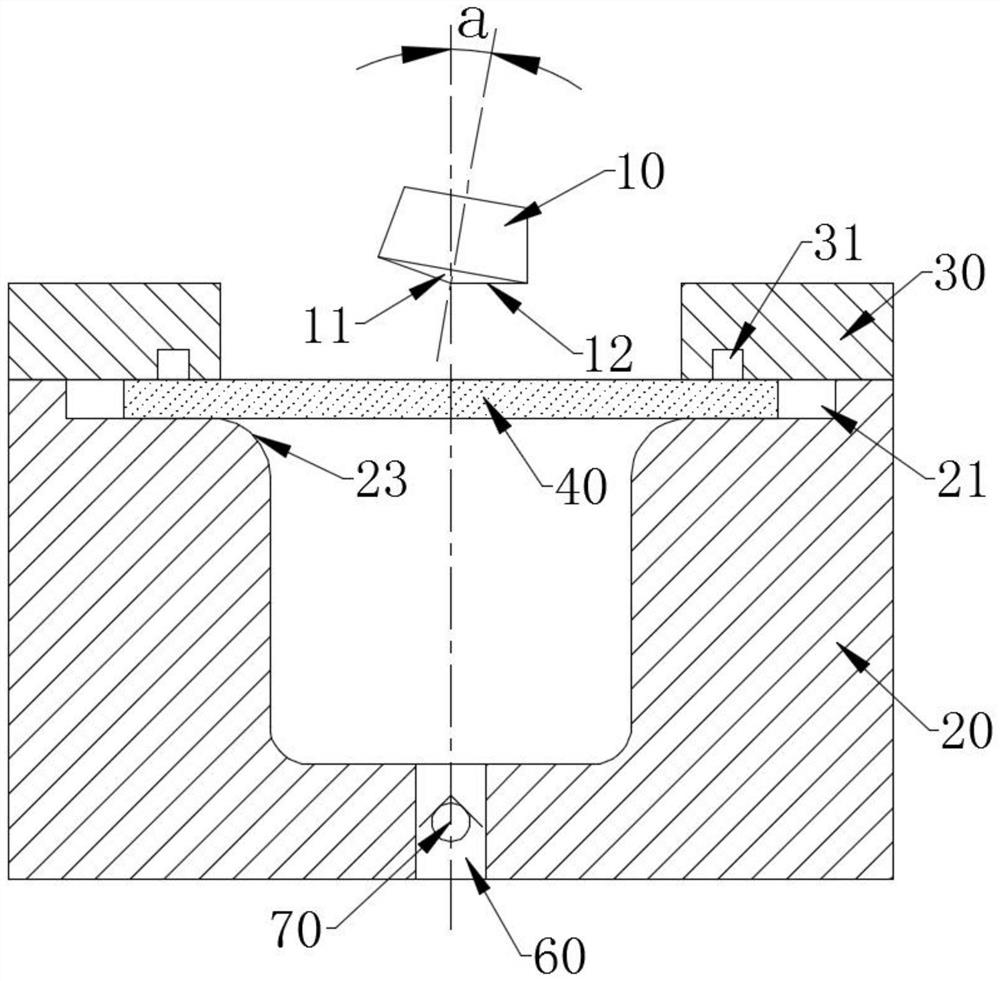

[0048] Such as Figure 1 to Figure 5 As shown, a rolling liquid-filled deep-drawing forming device for cylindrical parts includes a rolling punch 10 , a die 20 and a blank holder 30 .

[0049] Wherein, the blank holder 30 is movably arranged above the die 20, and the blank holder 30 is used to clamp the blank 40 to be formed between the blank holder 30 and the die 20. between.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com