Full-automatic numerical control machine tool cutting fluid recycling equipment

A technology for CNC machine tools and cutting fluids, which is applied in metal processing equipment, maintenance and safety accessories, metal processing machinery parts, etc. It can solve the problems of low cutting fluid recovery efficiency, affecting the smooth circulation of cutting fluid, and clogging of filters. Ensure the filtering effect and smoothness, ensure smooth flow, and prevent the effect of filter clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

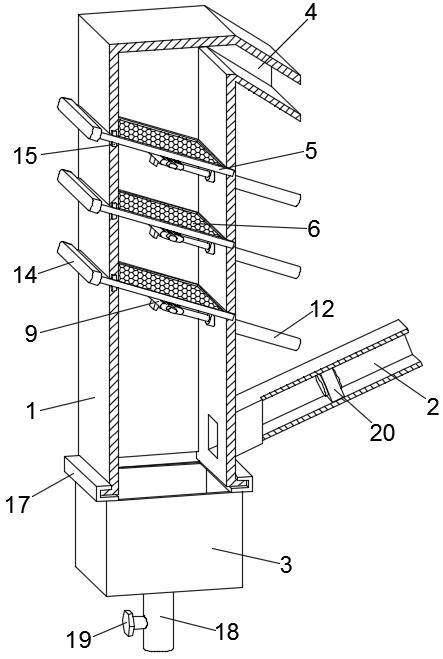

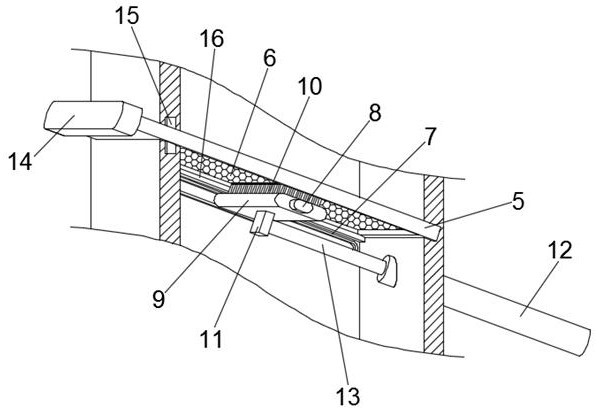

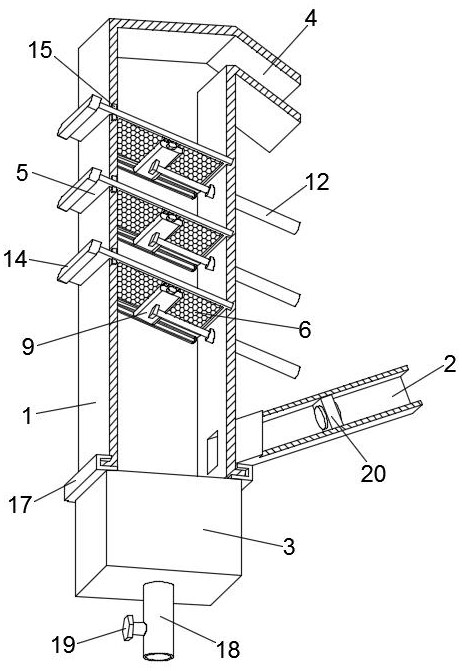

[0023] see Figure 1-2 , a fully automatic CNC machine tool cutting fluid recovery and utilization equipment, including a recovery bin 1, a recovery pipe 2 connected to one side of the lower end of the recovery bin 1, a chip collection box 3 at the bottom of the recovery bin 1, and a top of the recovery bin 1 There is a backflow port 4 on the side; several filter assemblies are arranged in the vertical direction in the recovery bin 1, and the filter assemblies include a sealing plate 5 and a filter screen 6, and the sealing plate 5 is inclined downward from the side wall of the recovery bin 1 It extends into the recovery bin 1 and is stuck on the inner wall of the opposite side of the recovery bin 1. A filter screen 6 is provided on the sealing plate 5, and a cleaning mechanism is provided below each filter assembly. The cleaning assembly includes a slide rail 7 and a mounting Plate 9, the slide rail 7 is fixedly installed on the inner wall of the recovery bin 1 and is consist...

Embodiment 2

[0033]A fully automatic CNC machine tool cutting fluid recycling equipment, including a recovery bin 1, a recovery pipe 2 connected to the lower end of the recovery bin 1, a chip collection box 3 at the bottom of the recovery bin 1, and a top side of the recovery bin 1 A return port 4 is provided; several filter assemblies are arranged in the vertical direction in the recovery bin 1, and the filter assemblies include a sealing plate 5 and a filter screen 6, and the sealing plate 5 extends obliquely downward from the side wall of the recovery bin 1. into the recovery bin 1 and is clamped on the inner wall of the opposite side of the recovery bin 1, a filter screen 6 is provided on the sealing plate 5, and a cleaning mechanism is provided under each filter assembly, and the cleaning assembly includes a slide rail 7 and a mounting plate 9. The slide rail 7 is fixedly installed on the inner wall of the recovery bin 1 and is consistent with the inclination of the filter screen 6. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com