Production technology of food-grade bidirectional film easy to uncover and easy to tear and pull

A production process and food-grade technology, which is applied in the field of food-grade two-way easy-to-remove and easy-tear film, can solve problems such as the inability to realize the automatic output of the rewinding roller, the inability to perform the automatic roll change of the rewinding roller, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

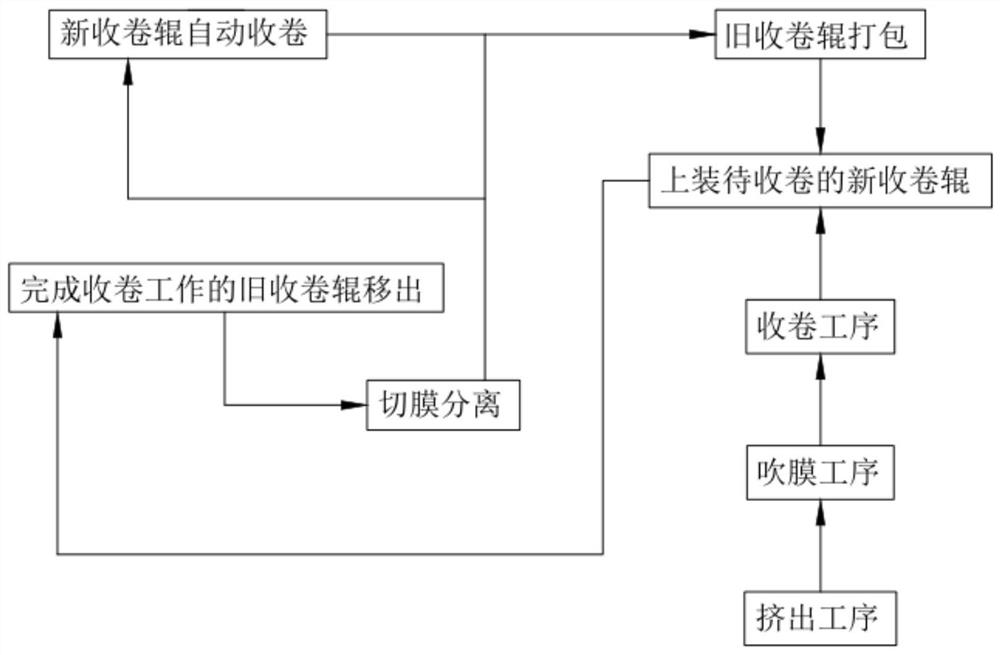

[0101] Such as figure 1 As shown, a food-grade two-way easy-to-open and easy-tear film production process includes the following steps:

[0102] Step 1, extrusion process, the extruder extrudes a food-grade two-way easy-to-remove and easy-tear film. The food-grade two-way easy-to-remove and easy-tear film includes three layers, wherein the content of the outer layer LDPE is ≥ 90%, and the content of COC is ≤ 10%; The content of middle layer LDPE≥75%, the content of HDPE≥10%, the content of COC≤10%; the content of inner layer EVA≥40% and ≤50%, the content of LDPE≥50% and ≤60%, the content of blocking agent ≤3%, the content of slip agent ≤3%;

[0103] Step 2, film blowing process. The film blowing process is set at the output end of the extrusion process. The film blowing machine blows the food-grade two-way easy-to-open and easy-tear film into a cylindrical shape, and flattens it after cooling output;

[0104] Step 3, a winding process, the winding process is set at the output...

Embodiment 2

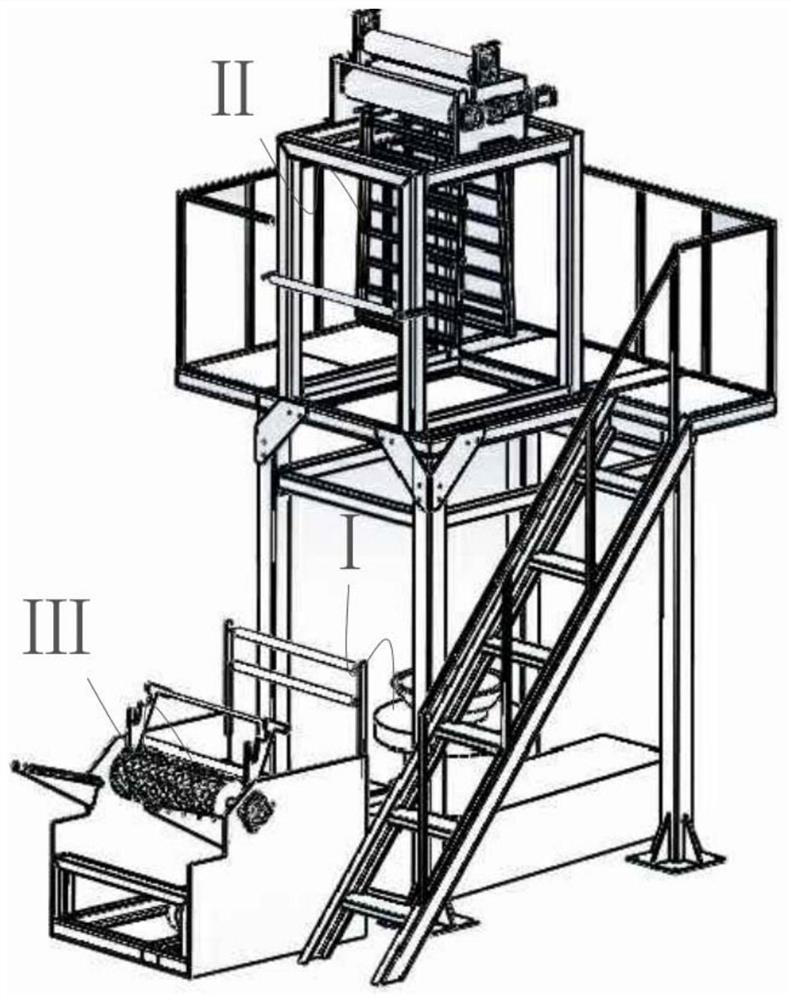

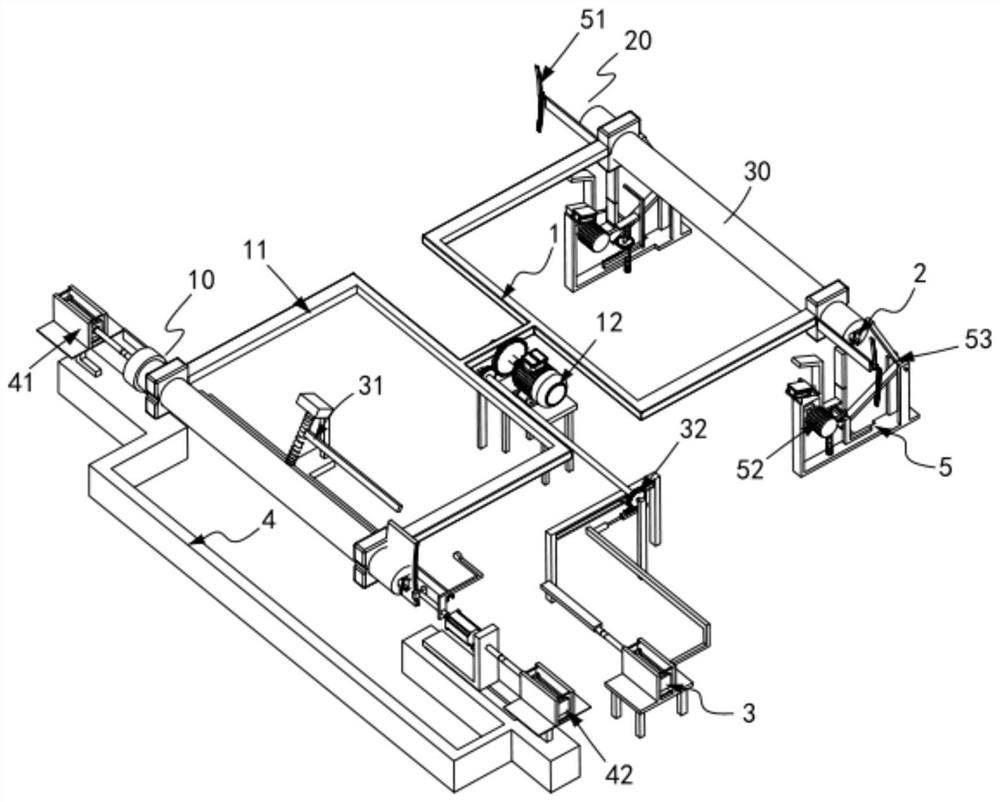

[0121] Such as Figure 4 , figure 2 and image 3 As shown, a food-grade two-way easy-to-open and easy-tear film production line includes an extruder I, a blown film machine II arranged on one side of the extruder I, and a receiving machine arranged at the output end of the blown film machine II. Winder III, the winder III includes:

[0122] Switching mechanism 1, one end of the switching mechanism 1 is a winding station 10 and the other end is a transmission station 20, the winding roller 30 is rotatably arranged on the switching mechanism 1 and a compensation assembly 2 is arranged therein, so The lower end of the winding roller 30 is provided with a fastening groove 2a;

[0123] The cutter mechanism 3, the cutter mechanism 3 is located between the winding station 10 and the transmission station 20, it includes a pressing assembly 31 located above the winding station 10, and the switching mechanism 1 Working synchronously and driving the cutting assembly 32 for cutting t...

Embodiment 3

[0180] Such as Figure 22 , Figure 21 and Figure 26 As shown, the parts that are the same as or corresponding to those in the second embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of simplicity, only the differences from the second embodiment will be described below. The difference between this embodiment three and embodiment two is:

[0181] further, such as Figure 21 , Figure 22 As shown, the second driving assembly 42 includes a second flat-push cylinder 422 installed on the frame e421 with its telescopic end horizontally arranged, fixedly connected with the telescopic end of the second flat-push cylinder 422 and slidingly arranged at the lower end The motor frame 423 in the limit slot of the frame e421, the second drive motor 424 installed on the motor frame 423, the plug 425 arranged at the output end of the second drive motor 424 and the second drive motor through the second drive motor The transmission of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com