Treatment method for enhancing temperature resistance and wear resistance of chain plate

A treatment method and wear resistance technology, applied in the field of transmission chains, can solve the problems of chain plate and pin shaft wear, failure to meet user life requirements, pin pitting, etc., to eliminate stress, enhance structural quality and stability , enhance the effect of combining strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

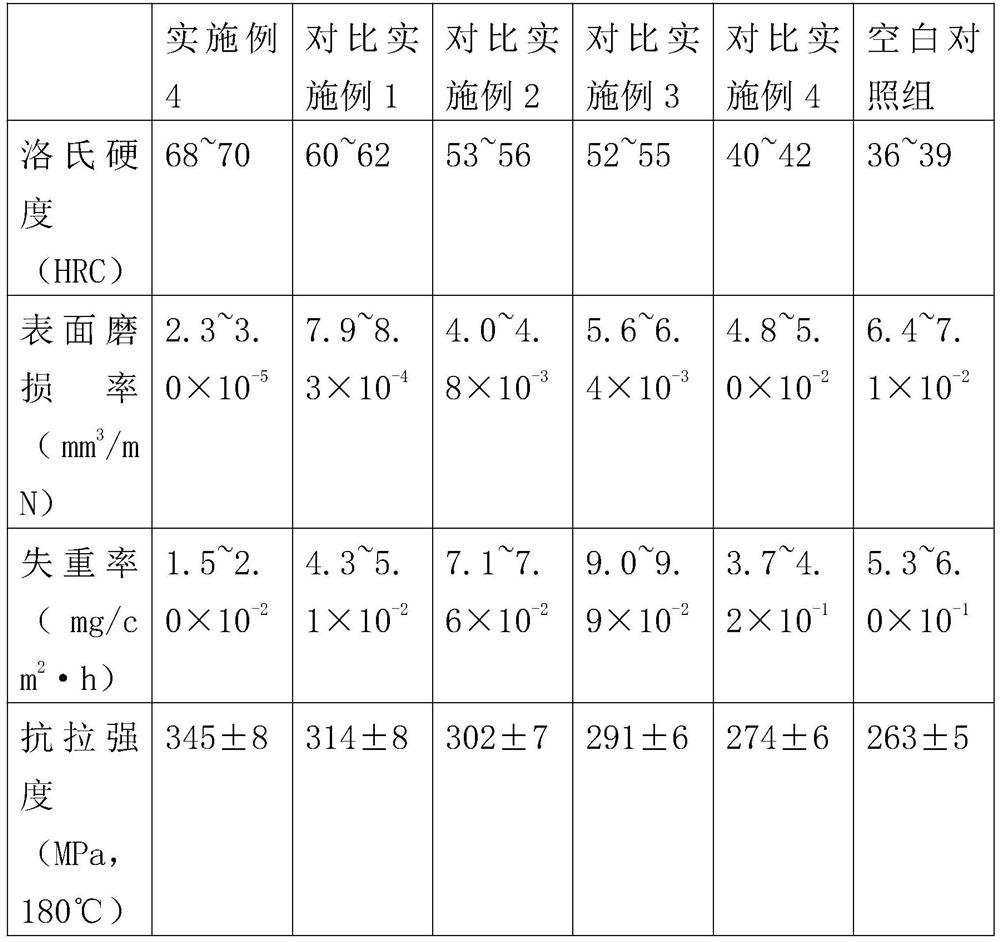

Examples

Embodiment 1

[0030] A treatment method for enhancing the temperature and wear resistance of chain plates, comprising the steps of:

[0031] (1) Cleaning treatment:

[0032] Immerse the chain plate in the acetone solution first, control the temperature of the acetone solution to 35°C, take it out after soaking for 25 minutes, and then rinse it with clean water for later use;

[0033] (2) Activation drying treatment:

[0034] Immerse the chain plates treated in step (1) in a sulfuric acid solution with a concentration of 80ml / L for activation treatment, take it out, rinse it with clean water, and then place it in an environment with a temperature of 85°C for drying treatment before use;

[0035] (3) Surface plating treatment:

[0036] Carry out electroplating treatment to the chain plate after step (2) treatment, the length of control electroplating treatment is 25min, after finishing it is taken out back for use; Used electroplating solution during electroplating treatment is made up of t...

Embodiment 2

[0046] A treatment method for enhancing the temperature and wear resistance of chain plates, comprising the steps of:

[0047] (1) Cleaning treatment:

[0048] Immerse the chain plate in the acetone solution first, control the temperature of the acetone solution to 38°C, take it out after soaking for 27 minutes, and then rinse it with clean water for later use;

[0049] (2) Activation drying treatment:

[0050] Immerse the chain plates treated in step (1) first in a sulfuric acid solution with a concentration of 82ml / L for activation treatment, take it out, rinse it with clean water, and then place it in an environment with a temperature of 88°C for drying treatment before use;

[0051] (3) Surface plating treatment:

[0052]Carry out electroplating treatment to the chain plate after step (2) treatment, the length of control electroplating treatment is 30min, after finishing it is taken out back for use; Used electroplating solution during electroplating treatment is made up...

Embodiment 3

[0062] A treatment method for enhancing the temperature and wear resistance of chain plates, comprising the steps of:

[0063] (1) Cleaning treatment:

[0064] Immerse the chain plate in the acetone solution first, control the temperature of the acetone solution to 40°C, take it out after soaking for 30 minutes, and then rinse it with clean water for later use;

[0065] (2) Activation drying treatment:

[0066] Immerse the chain plates treated in step (1) first in a sulfuric acid solution with a concentration of 85ml / L for activation treatment, take it out, rinse it once with clean water, and then place it in an environment with a temperature of 90°C for drying treatment before use;

[0067] (3) Surface plating treatment:

[0068] Carry out electroplating treatment to the chain plate after the step (2) process, control the duration of electroplating treatment to be 35min, take it out after completion and back up for later use; Used electroplating solution during electroplati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com