Atmosphere tubular furnace cooling device and cooling method

A technology for cooling devices and atmosphere tubes, which is applied to furnace cooling devices, furnaces, muffle furnaces, etc., and can solve problems such as pipeline cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

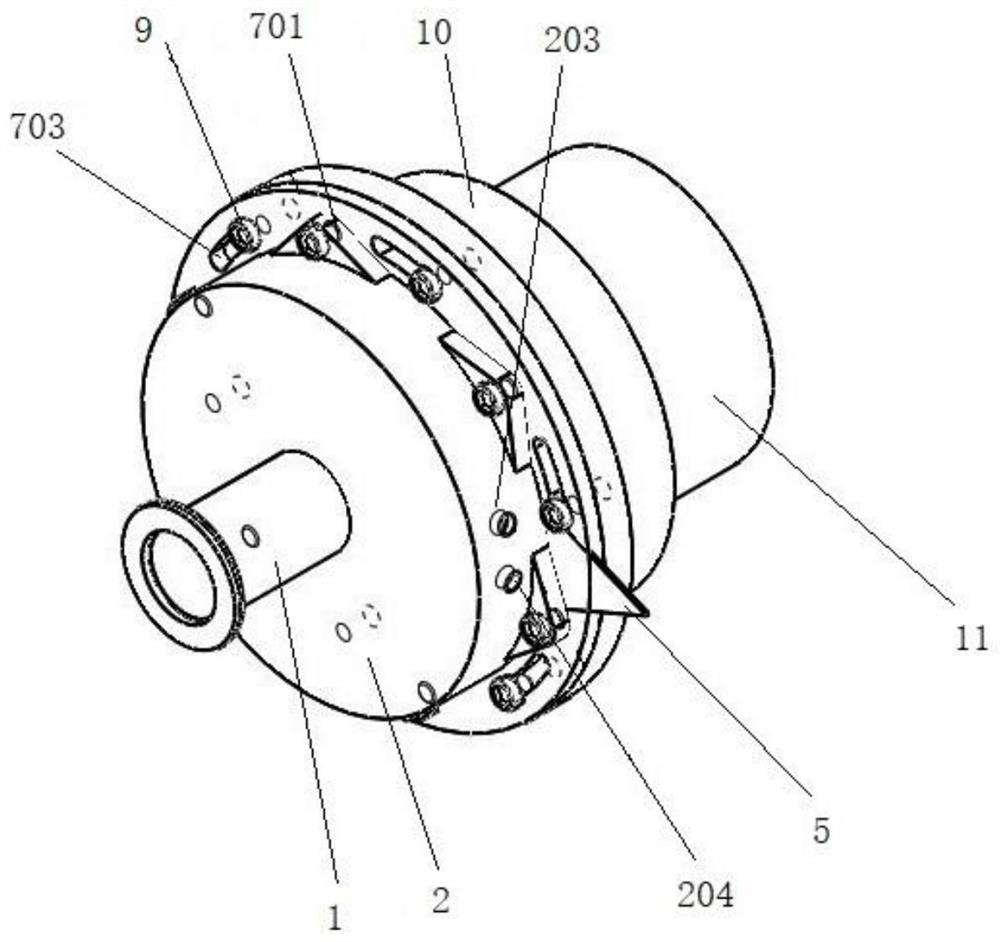

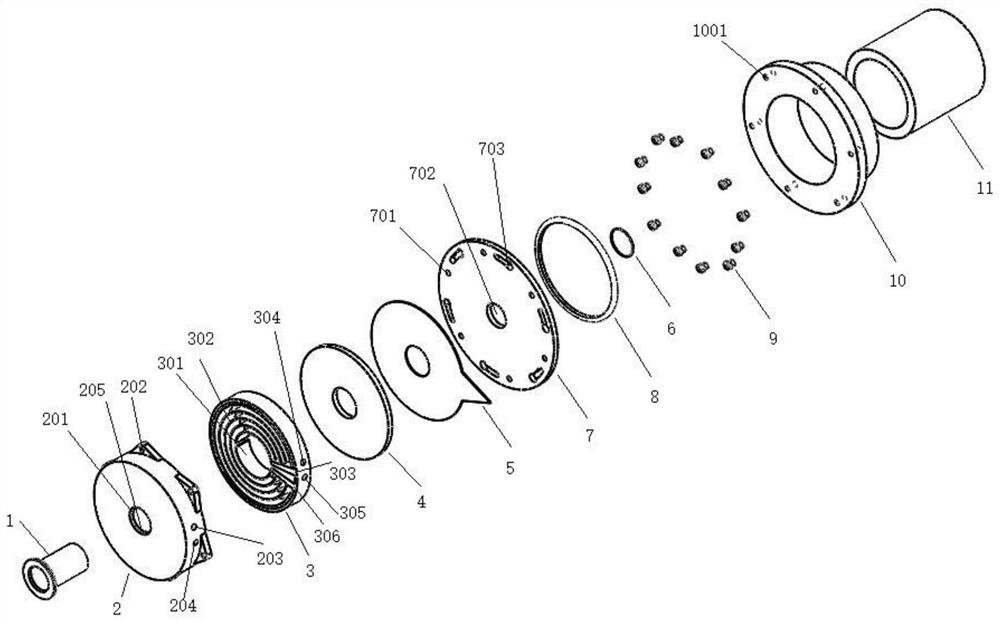

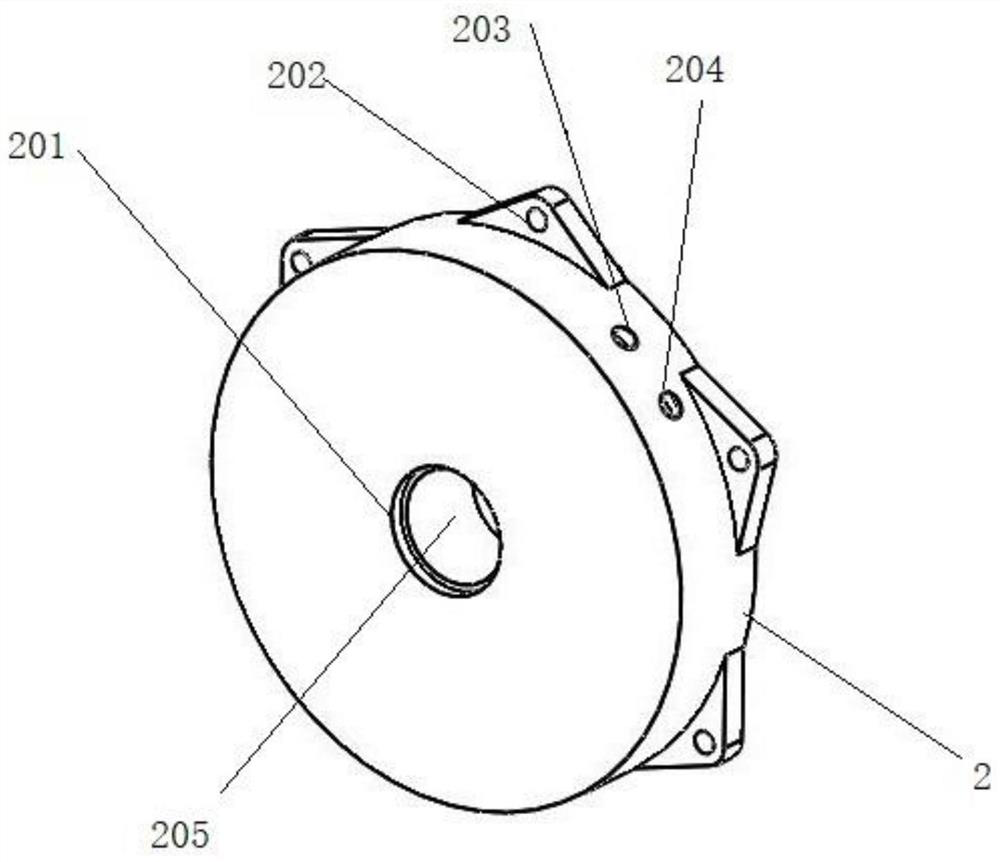

[0069] Such as figure 2 As shown, using the end cover 2 as an installation platform, the end cover 2 and the vacuum joint 1 are sealed and welded; the end cover 2, the heat conduction circuit 3, the sealing plate 4, the The silica gel pad 5, the ○-shaped sealing ring 6, the joint fixed plate 7, the sealing rubber ring 8, and the vacuum corundum tube 10 are concentrically matched, and the six locking nuts 9 are used to perform a balanced sealing lock. Tight connection.

[0070] There are six locking threaded holes 701 .

[0071] The locking threaded hole 701 is a fine threaded M4 threaded hole.

[0072] The threaded thin metal plate is a threaded copper thin plate.

[0073] The material of the O-shaped sealing ring 6 is stainless steel.

[0074] The material of the conduction water channel 3 is brass.

[0075] The material of the sealing disc 4 is brass.

[0076] The vacuum atmosphere tube furnace cooling device effectively solves the problem of heat dissipation at both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com