Solid engine thermal insulation layer ablation performance parallel assessment test device

A solid engine and ablation test technology, which is used in engine testing, jet engine testing, gas turbine engine testing, etc., can solve the evaluation of thermal insulation material ablation performance deviation, ablation environment fluctuations, and unfavorable thermal insulation material formulation improvement design. Evaluation and other issues to achieve the effect of reducing radial loss, easy installation and use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

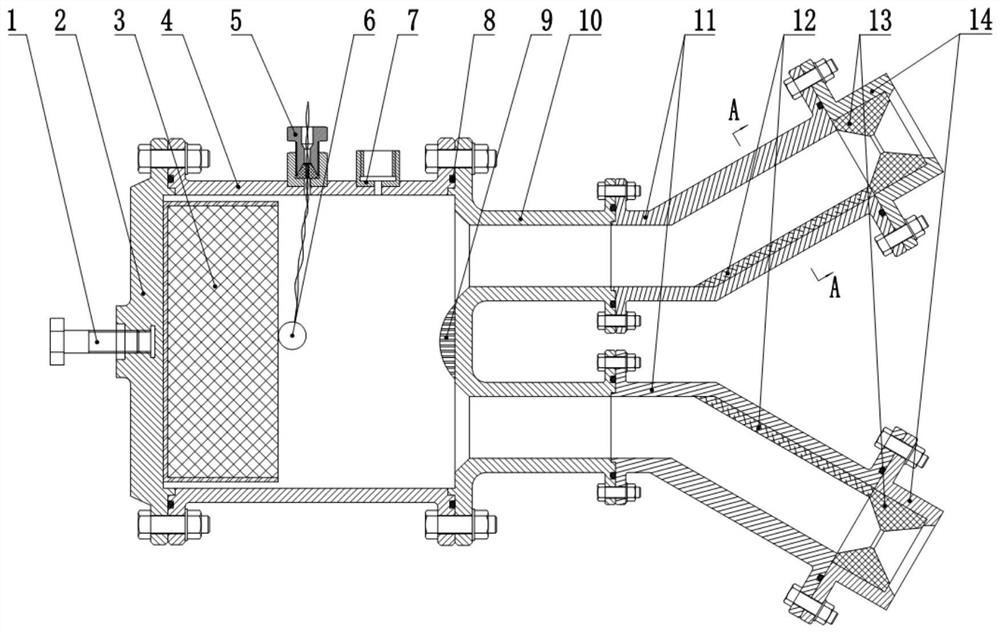

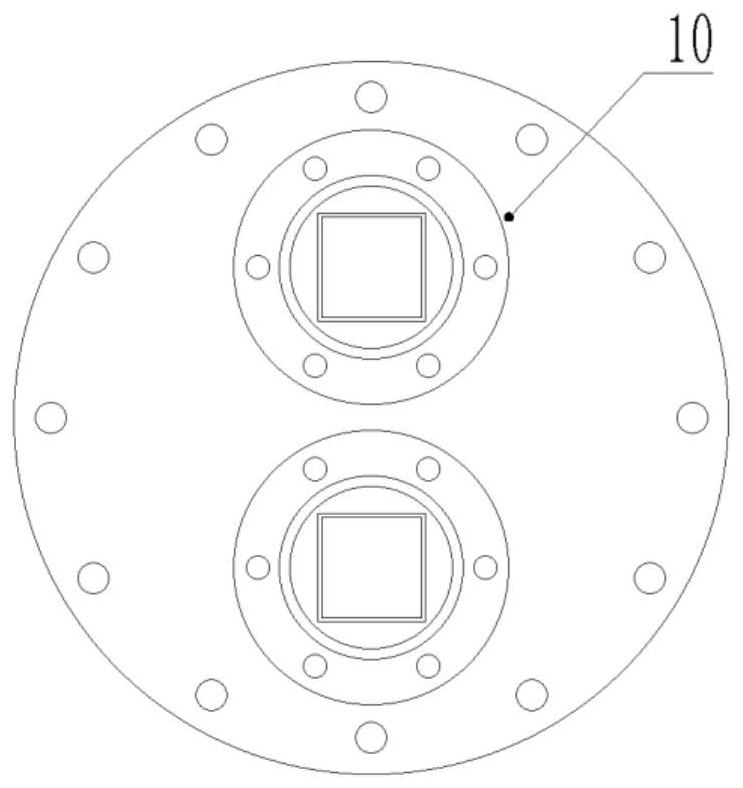

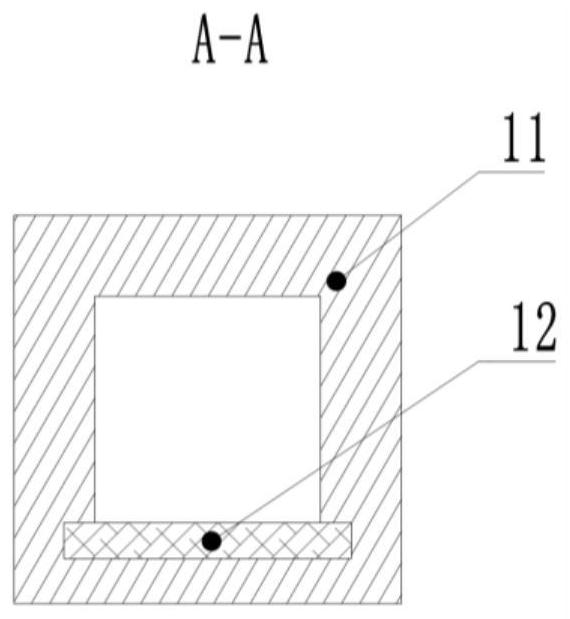

[0030]In this embodiment, a parallel assessment test device for the ablation performance of the solid engine heat insulation layer is processed and installed; among them, the front head ejector rod 1, the front head of the combustion chamber 2, the cylinder section 4 of the combustion chamber, the rear head of the combustion chamber 10, the ablation The test section 11 and the nozzle holder 14 respectively adopt 45 # The steel is processed and formed, and the sealing ring 8 is made of silicon rubber. The propellant 3 is a three-component hydroxybutylene propellant, which adopts a cylindrical grain that burns on the end face and covers the rest of the surface. The diameter of the grain is 200 mm, the length is 67.2 mm, and the thickness of the coating layer is 3 mm.

[0031] The combustion chamber section 4 has a length of 180mm, an outer diameter of 230mm, and an inner diameter of 210mm. The flanges at both ends of the combustion chamber section 4 have 12 uniform holes along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com