Novel cylindrical three-dimensional reconstruction method and system

A three-dimensional reconstruction and cylinder technology, applied to computational models, biological models, details involving processing steps, etc., can solve problems such as accuracy needs to be improved, errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

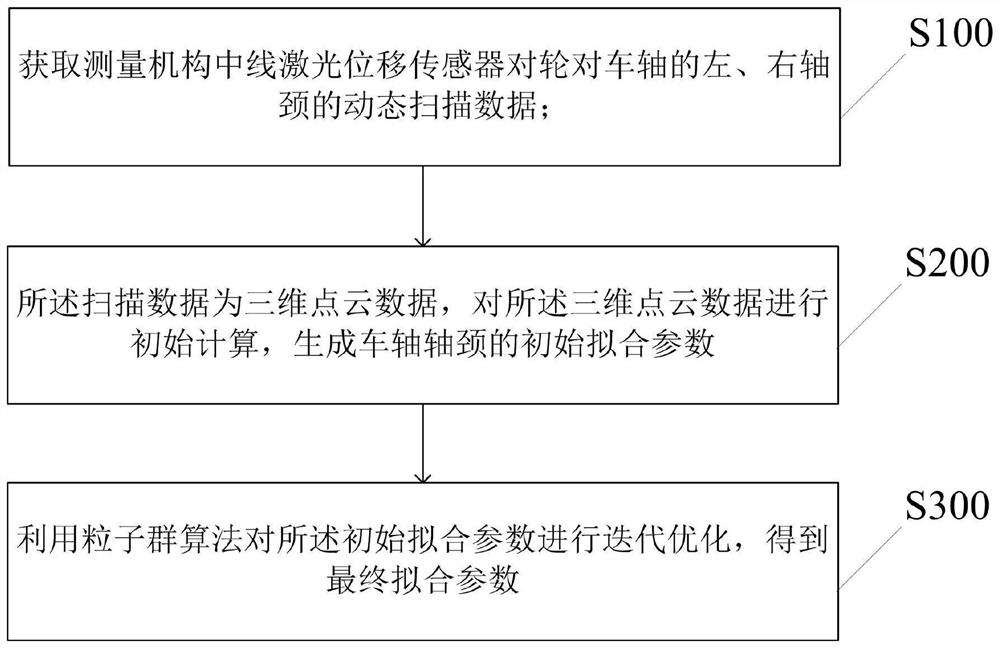

[0123] The embodiment of the present invention provides a novel cylinder three-dimensional reconstruction method, referring to figure 1 ,include:

[0124] S100. Obtain the dynamic scanning data of the centerline laser displacement sensor of the measuring mechanism on the left and right journals of the wheel set axle;

[0125] S200. The scanned data is three-dimensional point cloud data, and an initial calculation is performed on the three-dimensional point cloud data to generate initial fitting parameters of the axle journal;

[0126] S300. Using the particle swarm optimization algorithm to iteratively optimize the initial fitting parameters to obtain final fitting parameters.

[0127] In this embodiment, the measurement mechanism dynamically scans and detects the journal of the wheel set axle, obtains the surface data of the wheel set journal, obtains relatively accurate initial fitting parameters through three-dimensional reconstruction of the wheel set journal, and uses pa...

Embodiment 2

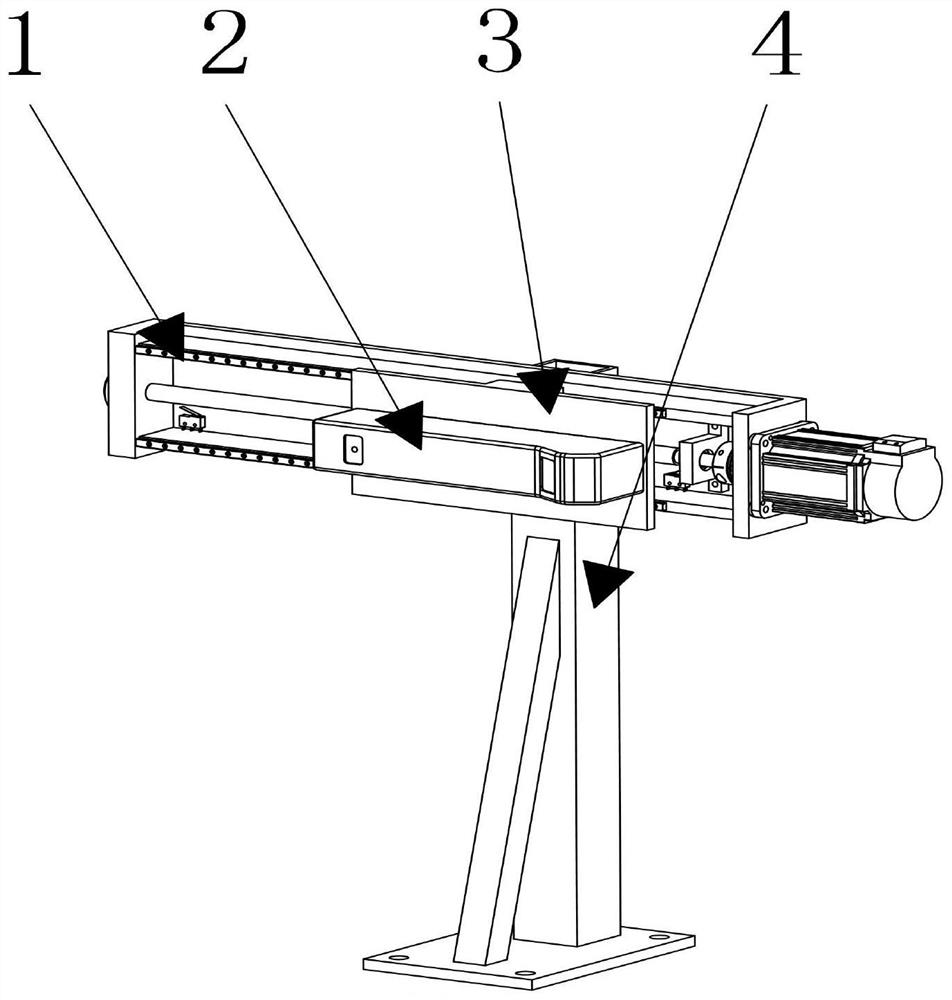

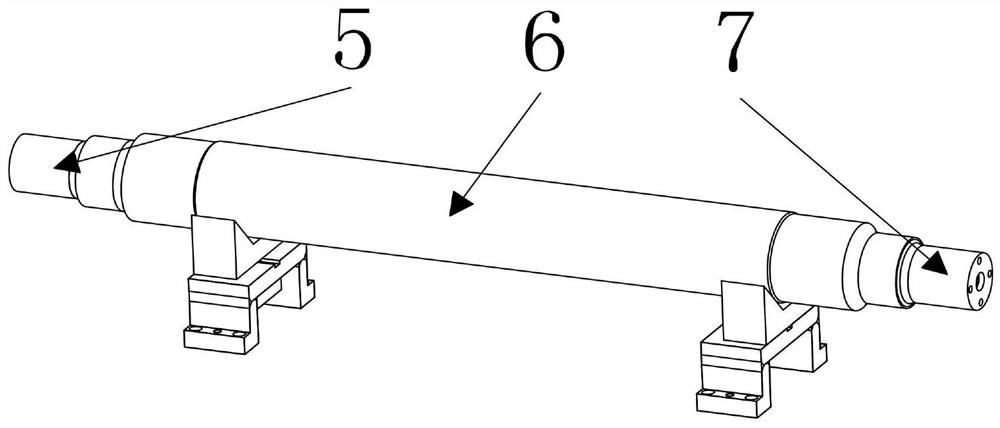

[0238] The embodiment of the present invention also provides a novel cylinder three-dimensional reconstruction system, referring to Figure 6 , including a measuring mechanism and a computing terminal 9;

[0239] Among them, the measuring mechanism is placed on one or both ends of the wheel set to be tested through the support frame 4; it is used to dynamically scan the left and right journals of the wheel set axle;

[0240] For example, the measuring mechanism is communicated with the computing terminal 9 through the router 8; during actual measurement, the supporting frame 4 of the measuring mechanism is fixed on one or both ends of the wheel set to be tested, and the linear displacement platform 1 drives the linear laser displacement sensor 2 of the wheel set to be tested. Dynamically scan the journal at one or both ends, obtain initial fitting parameters through the three-dimensional reconstruction method of the above embodiment, and then iteratively obtain the optimal fit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com