Preparation method of lithium-sulfur battery cathode

A lithium-sulfur battery and cathode technology, which is applied in the field of preparation of lithium-sulfur battery cathodes, can solve the problems of polysulfide shuttle, lithium-sulfur battery capacity decay, reduction of reaction active sites, etc., and achieves rapid lithium ion diffusion and electron transport, Achieving stable operation and widening the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

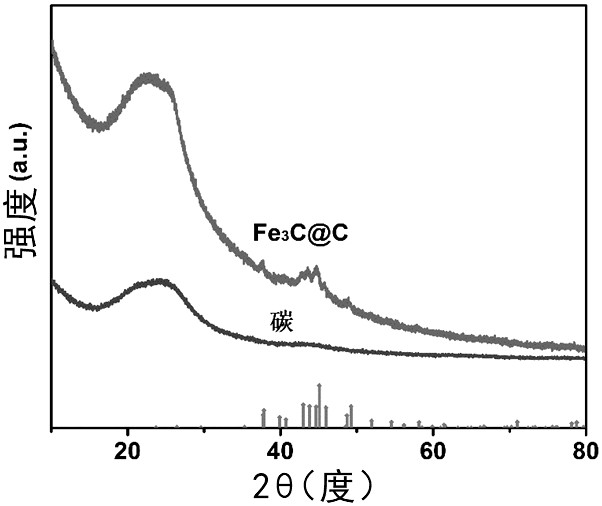

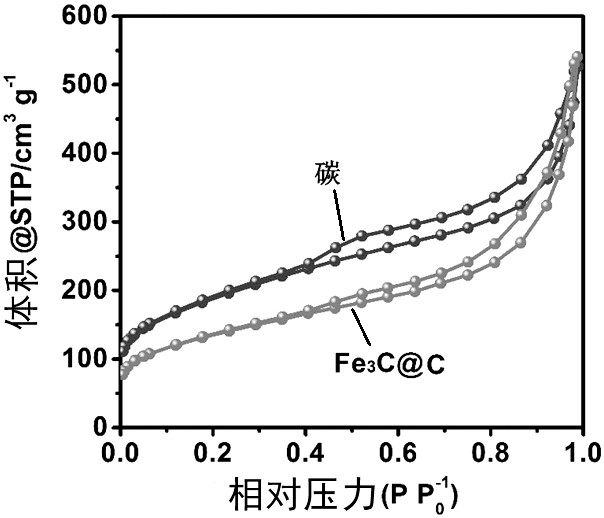

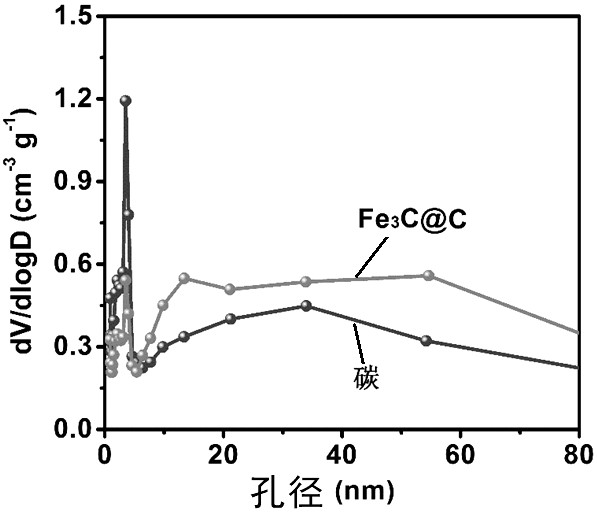

[0050] Step 1: Fe for low temperature and high areal capacity lithium-sulfur batteries 3 Preparation of C@C composites

[0051] (1) Mix 5g urea, 0.02 mol / L Fe(NO 3 ) 3 9H 2 0 and 160 mg of surfactant F127 were stirred and dissolved in 10 mL of deionized water to obtain a mixed solution A;

[0052] (2) Dissolve 0.25 g of glucosamine hydrochloride, 3.35 mL of silica gel and 540 µL of 0.5 M dilute sulfuric acid solution in 2 mL of deionized water, and stir to obtain mixed solution B;

[0053] (3) Slowly add the mixed solution B to the mixed solution A, and stir at room temperature to obtain the mixed solution C;

[0054] (4) Freeze-dry the above mixed solution C for 48 h;

[0055] (5) The sample obtained after freeze-drying was carbonized in a tube furnace under a nitrogen atmosphere. First, the temperature was raised to 500 °C at a rate of 5 °C / min and kept for 2 h, and then the temperature was raised to 900 °C at a rate of 5 °C / min. , keep warm for 2h;

[0056] (6) Cool ...

Embodiment 2

[0075] Step 1: Fe for low temperature and high areal capacity lithium-sulfur batteries 3 Preparation of C@C composites

[0076] (1) Mix 10g urea, 0.04 mol / L Fe(NO 3 ) 3 9H 2 0 and 160 mg surfactant F127 were stirred and dissolved in 20 mL deionized water to obtain mixed solution A;

[0077](2) Dissolve 0.5 g of glucosamine hydrochloride, 5 mL of silica gel and 540 µL of 0.5 M dilute sulfuric acid solution in 2 mL of deionized water, and stir to obtain mixed solution B;

[0078] (3) Slowly add the mixed solution B to the mixed solution A, and stir at room temperature to obtain the mixed solution C;

[0079] (4) Freeze-dry the above mixed solution C for 48 h;

[0080] (5) The sample obtained after freeze-drying was carbonized in a tube furnace under a nitrogen atmosphere. First, the temperature was raised to 500 °C at a rate of 5 °C / min and kept for 2 h, and then the temperature was raised to 900 °C at a rate of 5 °C / min. , keep warm for 2h;

[0081] (6) Cool to room temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com