Preparation method of lithium battery with Pd-Cu net/lithium metal composite material electrode

A composite material, lithium metal technology, applied in the manufacture of electrolyte batteries, electrode carriers/current collectors, non-aqueous electrolyte batteries, etc., can solve problems such as hidden dangers, battery failure safety, battery short circuit, etc. The effect of cycle life and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Below in conjunction with specific implementation example, above-mentioned scheme is described further, and preferred embodiment of the present invention is described in detail as follows:

[0035] In this example, a preparation method of a lithium battery with a Pd-Cu mesh / lithium metal composite electrode uses a composite material made of palladium (Pd) and copper mesh (Cu mesh) as a three-dimensional current collector to suppress lithium The growth of dendrite, thereby realizes the preparation of long-life lithium battery, and its method comprises the steps:

[0036] (1) Prepare palladium nitrate mixed solution:

[0037] The palladium nitrate of 200mg is dissolved in the glass beaker that 40mL deionized water is housed, stir well, make palladium nitrate mixed solution;

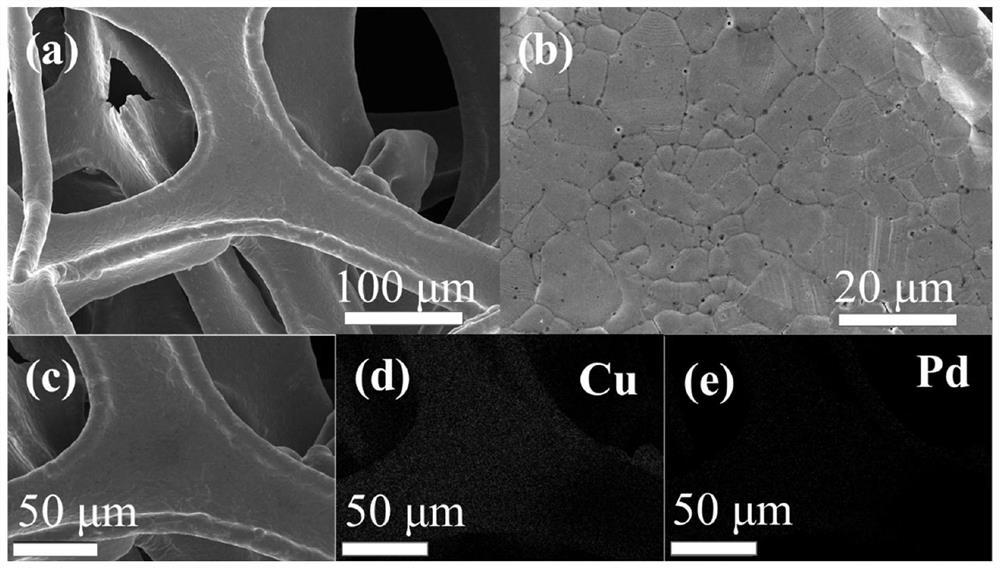

[0038] (2) Preparation of Pd-Cu copper mesh composite material:

[0039] Put the cleaned Cu mesh into the palladium nitrate mixed solution prepared in the step (1), soak for 5 minutes, take out the...

Embodiment 2

[0059] This embodiment is basically the same as Embodiment 1, especially in that:

[0060] In this example, a preparation method of a lithium battery with a Pd-Cu mesh / lithium metal composite electrode uses a composite material made of palladium (Pd) and copper mesh (Cu mesh) as a three-dimensional current collector to suppress lithium The growth of dendrite, thereby realizes the preparation of long-life lithium battery, and its method comprises the steps:

[0061] (1) Prepare palladium nitrate mixed solution:

[0062] The palladium nitrate of 300mg is dissolved in the glass beaker that the deionized water of 60mL is housed, stir well, make palladium nitrate mixed solution;

[0063] (2) Preparation of Pd-Cu copper mesh composite material:

[0064] Put the cleaned Cu mesh into the palladium nitrate mixed solution prepared in the step (1), soak for 10 minutes, take out the Cu mesh, put it in a vacuum oven to dry, and finally make a Pd-Cu mesh composite Material;

[0065] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com