Preparation method of antibacterial chlorophyll wound spray solution and extraction device

The technology of an extraction device and a production method is applied in the field of the production method of chlorophyll Chuangke spray bacteriostatic liquid and the extraction device, which can solve the problems of slow extraction and concentration, difficult absorption of chlorophyll, high labor intensity of workers, etc., so as to improve the extraction rate and facilitate the The effect of normal preservation and improvement of utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

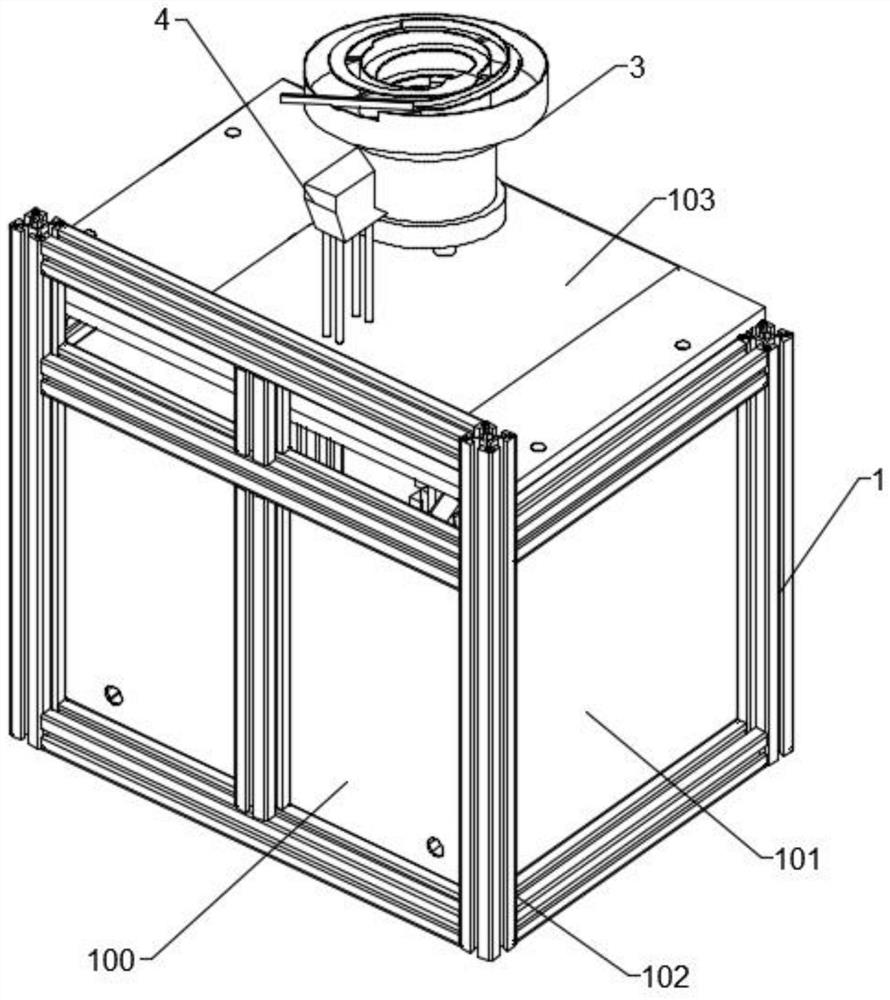

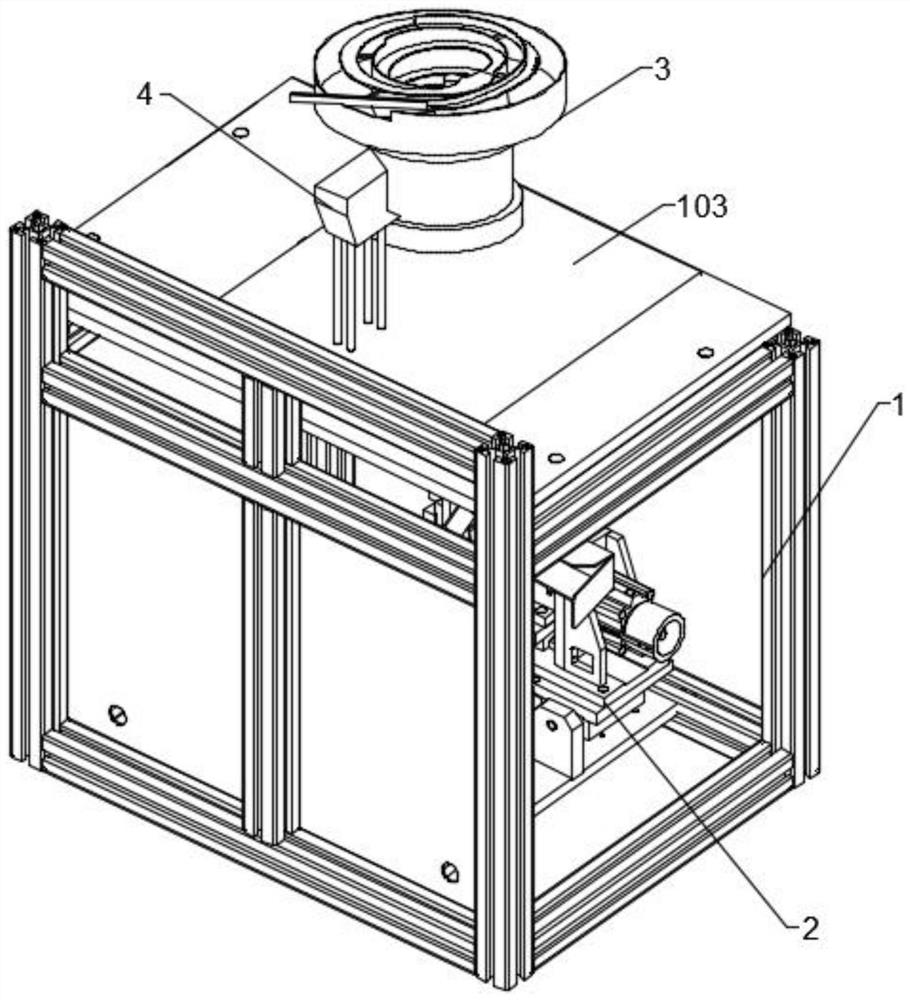

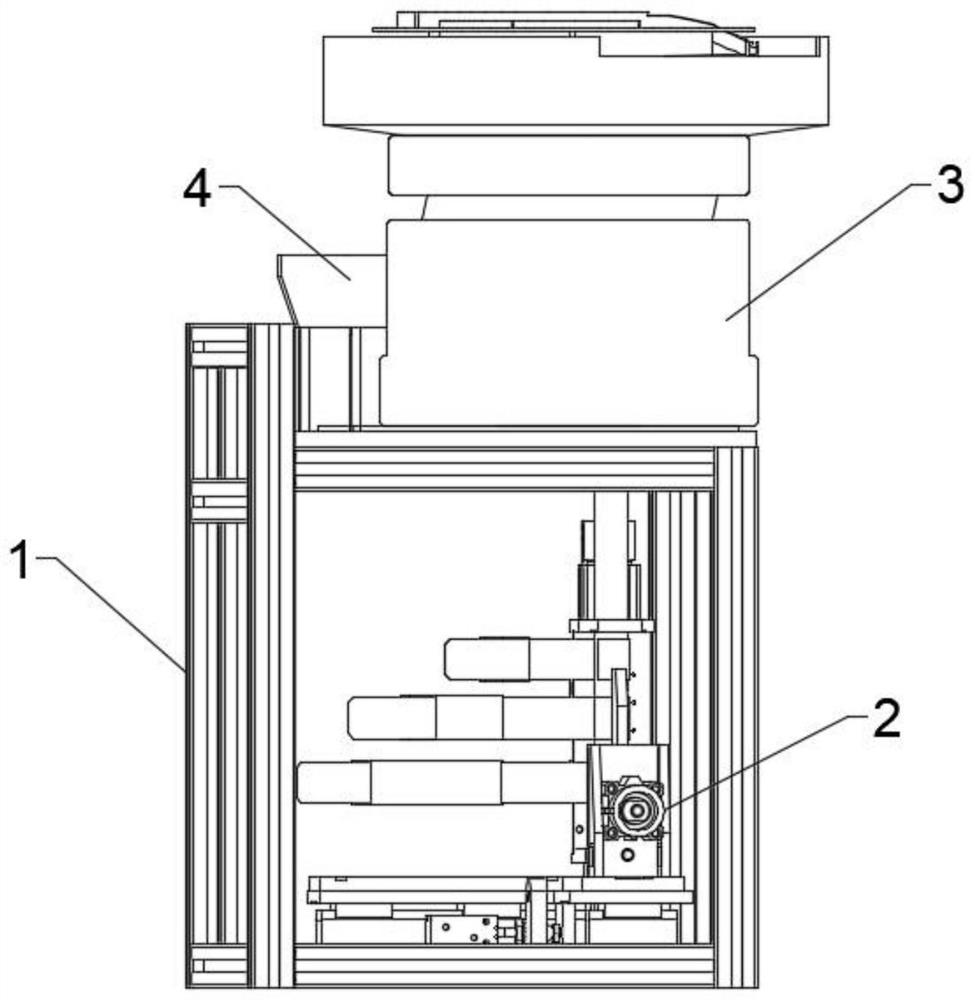

[0054] Such as Figure 1-Figure 8 Shown, the extracting device that adopts when chlorophyll can spray antibacterial liquid to make comprises frame 1, mashing mechanism 3 and leaching mechanism 2; A zigzag frame 103 can be detachably installed with a machine cover, and the frame 1 is surrounded by two first side panels 100 and two second side panels 102. A closing plate is installed, and a first through hole is opened on the closing plate;

[0055] The smashing mechanism 3 is installed on the top of the frame 1. The smashing mechanism 3 includes a smashing box, a crushing assembly and a feeding assembly. The feeding assembly includes a vibrating plate, a feeding track, and a feeding track. Above the plate, the feed track has a feed port, and the end of the feed track is connected to the head of the feed track. The feed track is installed on the top of the vibrating plate in a gradually descending spiral. Placed directly above the storage space, a vibrating structure is connec...

Embodiment 2

[0058] Such as Figure 1-Figure 10 As shown, the extraction device used in the production of the chlorophyll creative spray bacteriostatic liquid comprises a frame 1, a smashing mechanism 3 and a leaching mechanism 2; the frame 1 is surrounded by four square frames 103 to form a three-dimensional frame structure, wherein Three zigzag frames 103 are detachably installed with a machine cover, and the frame 1 is enclosed by two first side plates 100 and two second side plates 102 around, and a support plate 103 is installed on the top of the frame 1, and the frame 1 A closing plate is installed on the lower part, and a first through hole is opened on the closing plate;

[0059] The smashing mechanism 3 is installed on the top of the frame 1. The smashing mechanism 3 includes a smashing box, a crushing assembly and a feeding assembly. The feeding assembly includes a vibrating plate, a feeding track, and a feeding track. Above the plate, the feed track has a feed port, and the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com