A kind of preparation method and product thereof of anti-segregation agent for concrete

An anti-segregation agent and concrete technology, which is applied in the field of concrete admixtures, can solve problems such as segregation, and achieve the effects of simple production process, large water absorption effect, and enlarged volume capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

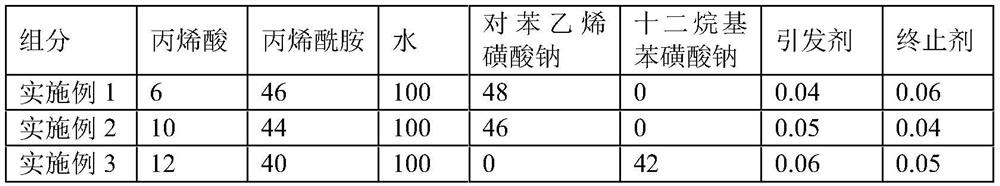

Embodiment 1

[0049] An anti-segregation agent for concrete is prepared through the following steps:

[0050] Step 1: Put 46 parts of acrylamide, 6 parts of acrylic acid and 100 parts of water into the reaction kettle, and stir at room temperature until the acrylamide is completely dissolved for 20 minutes to form a mixed solution A;

[0051] Step 2: Heat the mixed solution A obtained in Step 1, the temperature is controlled at 85° C., and the holding time is 3 hours. In the mixed solution A, acrylamide and acrylic acid are copolymerized, and acrylamide is homopolymerized to form a mixed solution B;

[0052] Step 3: Cool down the mixed solution B, control the temperature at 50° C., slowly add 20 wt % sodium hydroxide aqueous solution dropwise, adjust the pH value to 7.8, and form mixed solution C;

[0053] Step 4: Add 48 parts of sodium p-styrene sulfonate to the mixed solution C obtained in step 3, control the temperature at 50° C., add water while stirring to dissolve the sodium p-styrene...

Embodiment 2

[0057] An anti-segregation agent for concrete is prepared through the following steps:

[0058] Step 1: Put 44 parts of acrylamide, 10 parts of acrylic acid and 100 parts of water into the reaction kettle, and stir at room temperature until the acrylamide is completely dissolved for 20 minutes to form a mixed solution A;

[0059] Step 2: Heat the mixed solution A obtained in Step 1, the temperature is controlled at 90° C., and the holding time is 3 hours. In the mixed solution A, acrylamide and acrylic acid are copolymerized, and acrylamide is homopolymerized to form a mixed solution B;

[0060] Step 3: Cool down the mixed solution B, control the temperature at 55° C., slowly add 20 wt % sodium hydroxide aqueous solution dropwise, adjust the pH value to 8.2, and form mixed solution C;

[0061] Step 4: Add 46 parts of sodium p-styrene sulfonate to the mixed solution C obtained in step 3, control the temperature at 55° C., add water while stirring to dissolve the sodium p-styren...

Embodiment 3

[0065] An anti-segregation agent for concrete is prepared through the following steps:

[0066] Step 1: Put 40 parts of acrylamide, 12 parts of acrylic acid and 100 parts of water into the reaction kettle, and stir at room temperature until the acrylamide is completely dissolved for 20 minutes to form a mixed solution A;

[0067] Step 2: Heating the mixed solution A obtained in Step 1, the temperature is controlled at 95° C., and the holding time is 3 hours. In the mixed solution A, acrylamide and acrylic acid are copolymerized, and acrylamide is homopolymerized to form a mixed solution B;

[0068] Step 3: Cool down the mixed solution B, control the temperature at 60°C, slowly add 28%wt ammonia solution dropwise, adjust the pH value to 9.5, and form the mixed solution C;

[0069] Step 4: Add 42 parts of sodium dodecylbenzene sulfonate to the mixed solution C obtained in step 3, control the temperature at 60°C, add water while stirring to dissolve the sodium dodecylbenzene sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com