Ceramic tile with natural touch and preparation method thereof

A ceramic tile and tactile technology, applied in the field of building materials, to achieve the effect of reducing thermal conductivity, high flexural strength, and increasing the strength of the hole wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

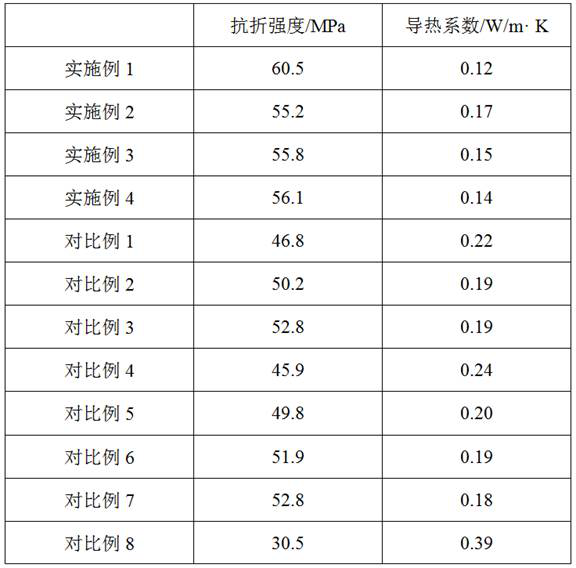

Embodiment 1

[0029] A ceramic tile with a natural touch, made of the following raw materials in parts by weight: 22 parts of mullite, 12 parts of illite, 12 parts of quartz powder, 10 parts of clay, 8 parts of bauxite, 7 parts of modified glass fiber, 6 parts of modified gangue powder, 5.5 parts of microplagioclase, 3 parts of tungsten carbide, 2 parts of burnt talc, and 1.5 parts of diboron trioxide.

[0030] The preparation method of described modified glass fiber is:

[0031] Add 24 parts of glass fiber to 76 parts of 1.1mol / L hydrochloric acid solution, let it stand for 8 hours, and dry to obtain pretreated glass fiber; add 25 parts of ferric oxide to 1225 parts of concentrated hydrochloric acid to prepare a mixed solution (containing Ferric oxide 2% mixture);

[0032] Take 12 parts of pretreated glass fibers and 0.3 parts of kh550 and add them to 120 parts of the mixture, treat them with ultrasonic waves for 40 minutes, and dry them to obtain modified glass fibers.

[0033] The ultr...

Embodiment 2

[0044] A ceramic tile with a natural touch, made of the following raw materials in parts by weight: 20 parts of mullite, 10 parts of illite, 10 parts of quartz powder, 8 parts of clay, 6 parts of bauxite, 6 parts of modified glass fiber, 4 parts of modified coal gangue powder, 4 parts of microplagioclase, 2 parts of tungsten carbide, 1 part of calcined talc, and 1 part of diboron trioxide.

[0045] The preparation method of described modified glass fiber is:

[0046]Add 24 parts of glass fiber to 76 parts of 1.1mol / L hydrochloric acid solution, let it stand for 8 hours, and dry to obtain pretreated glass fiber; add 25 parts of ferric oxide to 1225 parts of concentrated hydrochloric acid to prepare a mixed solution (containing Ferric oxide 2% mixture);

[0047] Take 12 parts of pretreated glass fibers and 0.3 parts of kh550 and add them to 120 parts of the mixture, treat them with ultrasonic waves for 40 minutes, and dry them to obtain modified glass fibers.

[0048] The ultr...

Embodiment 3

[0059] A ceramic tile with a natural touch, made of the following raw materials in parts by weight: 30 parts of mullite, 20 parts of illite, 20 parts of quartz powder, 15 parts of clay, 10 parts of bauxite, 10 parts of modified glass fiber, 8 parts of modified coal gangue powder, 8 parts of microplagioclase, 5 parts of tungsten carbide, 4 parts of burnt talc, and 4 parts of diboron trioxide.

[0060] The preparation method of described modified glass fiber is:

[0061] Add 24 parts of glass fiber to 76 parts of 1.1mol / L hydrochloric acid solution, let it stand for 8 hours, and dry to obtain pretreated glass fiber; add 25 parts of ferric oxide to 1225 parts of concentrated hydrochloric acid to prepare a mixed solution (containing Ferric oxide 2% mixture);

[0062] Take 12 parts of pretreated glass fibers and 0.3 parts of kh550 and add them to 120 parts of the mixture, treat them with ultrasonic waves for 40 minutes, and dry them to obtain modified glass fibers.

[0063] The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com