Movable combined cycle power generation system

A technology for combined cycle power generation and power generation sub-systems, applied in the direction of combined combustion mitigation, electromechanical devices, electrical components, etc., can solve the problems of low power generation efficiency of mobile power generation systems, and the power generation efficiency is difficult to exceed 20%. Effects of mobility, improved energy efficiency, and increased power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0034] The invention will be described in detail below with reference to the accompanying drawings and examples.

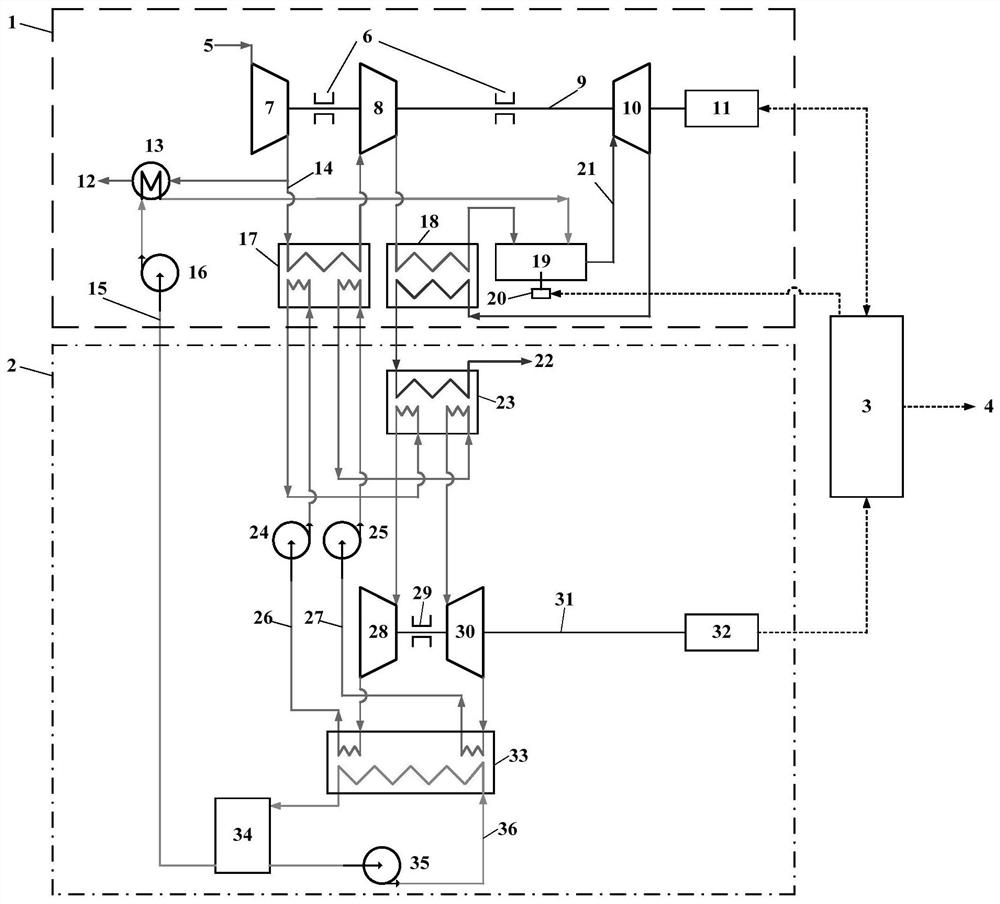

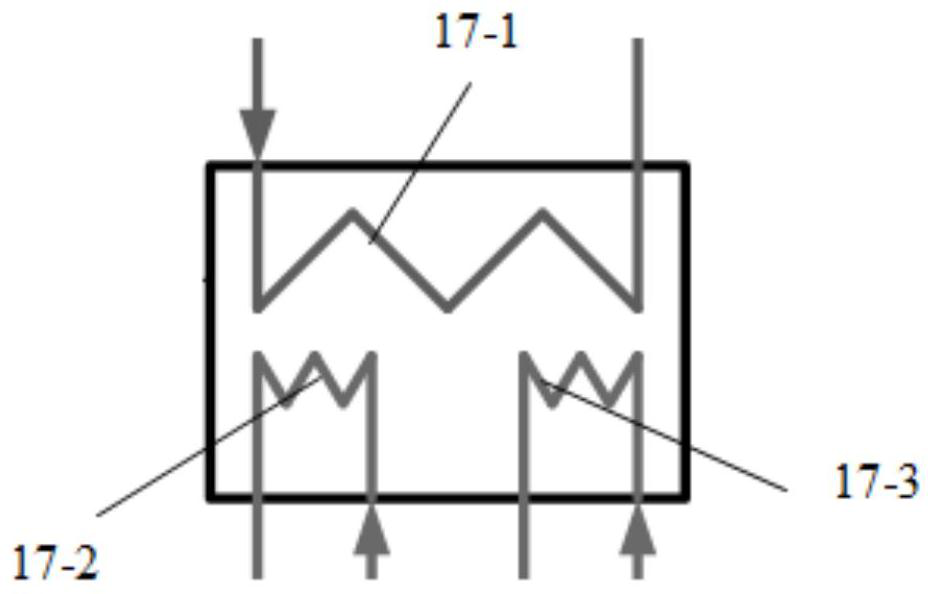

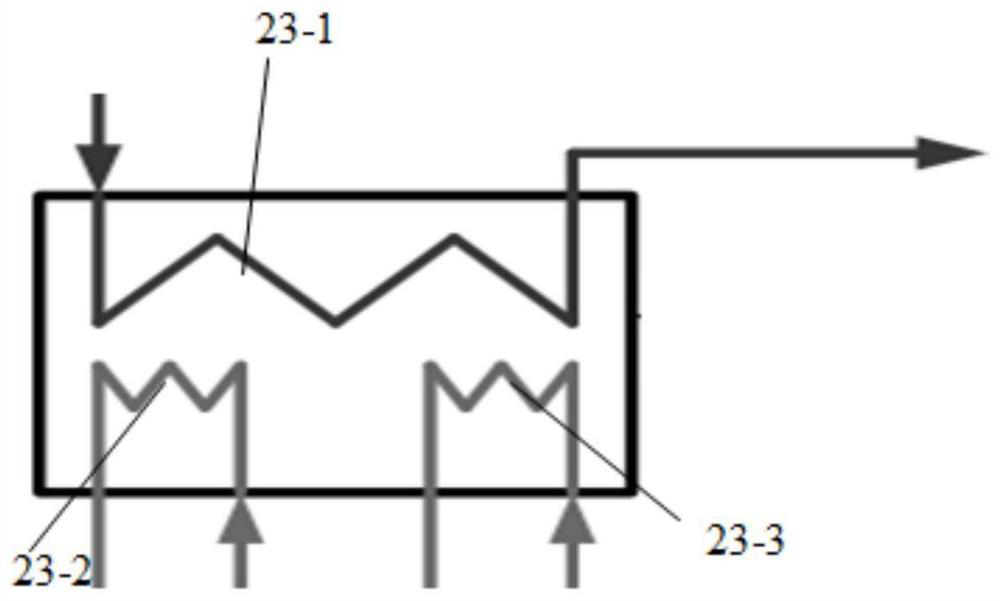

[0035] Such as figure 1As shown, a mobile combined cycle power generation system includes a single-stage micro gas turbine power generation sub-system 1, a two-stage organic Rankine cycle power generation sub-system 2 and a battery pack 3, and the single-stage micro gas turbine power generation sub-system 1 includes Stage I compressor 7, Stage II compressor 8, combustion chamber 19, turbine 10, regenerator 18, heat exchanger one 13, heat exchanger two 17, air-cooled generator one 11, rotor one 9 and fuel pump 16 The two-stage organic Rankine cycle power generation subsystem includes a first-stage drive pump 24, a second-stage drive pump 25, a first-stage circulating working medium 26, a second-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com