Fluorine-lined pipe flue gas heating system

A flue gas heating and fluorine-lined technology, applied in the field of flue gas treatment, can solve the problems of shortened service life, increased maintenance cost of heating system, poor corrosion resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

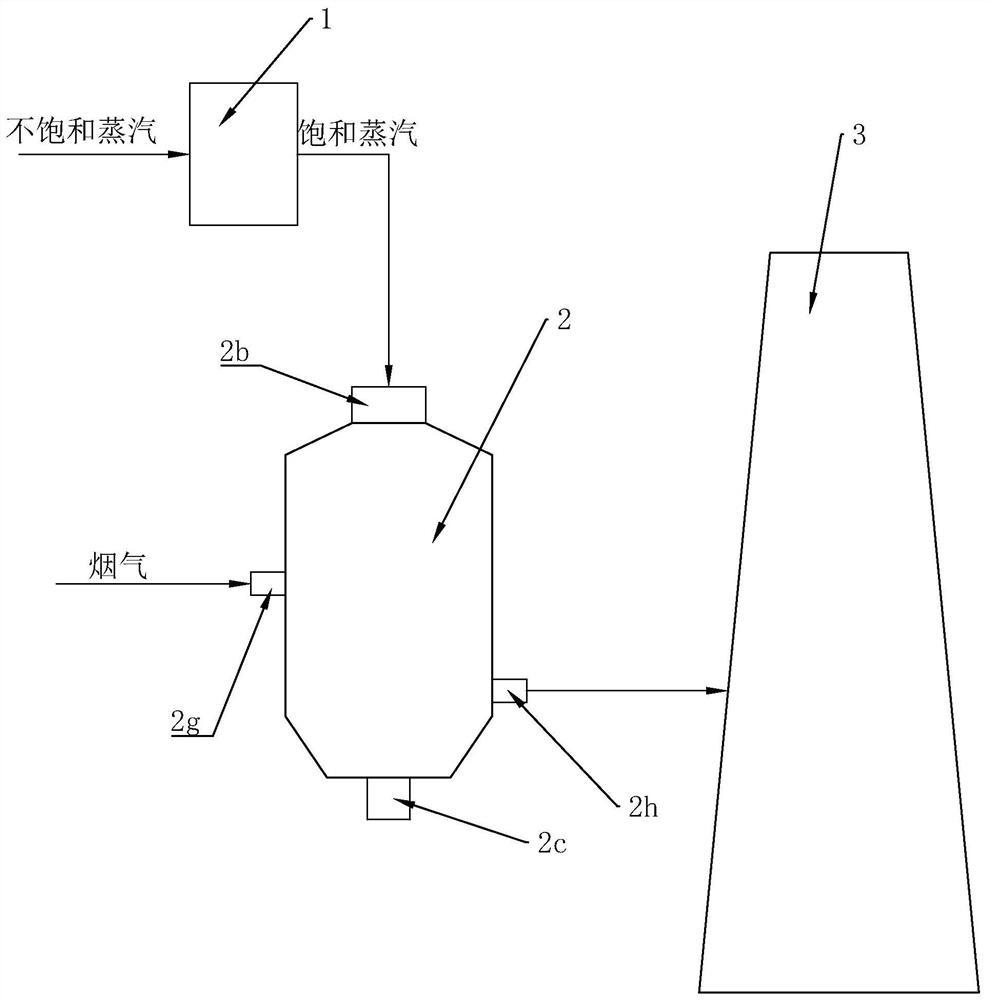

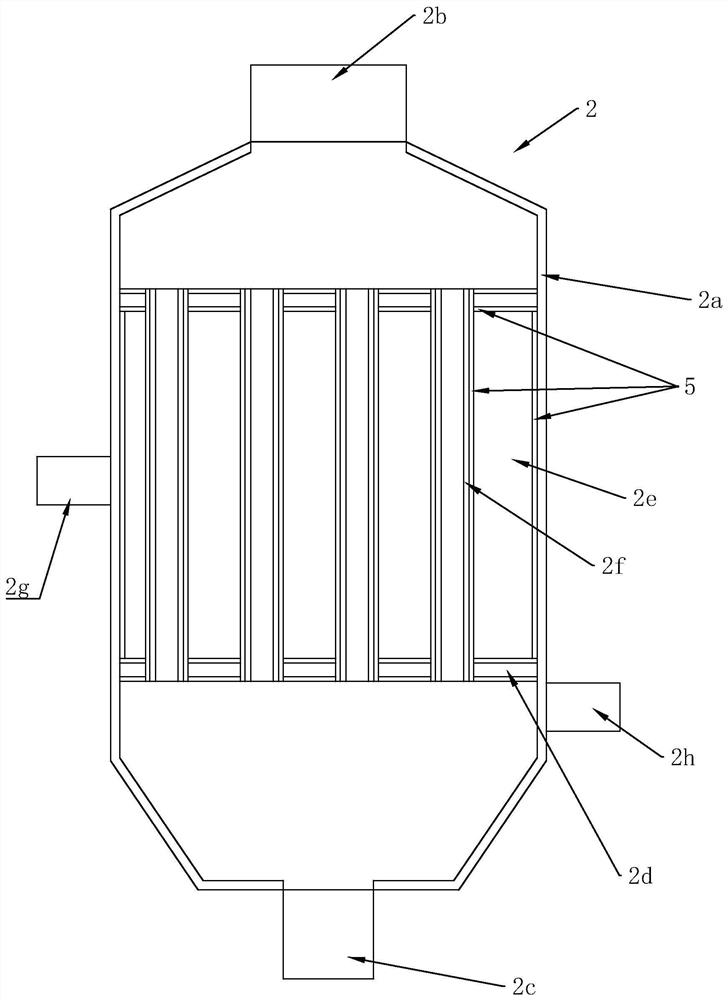

[0035] refer to Figure 1 to Figure 3 An embodiment of the present invention will be further described.

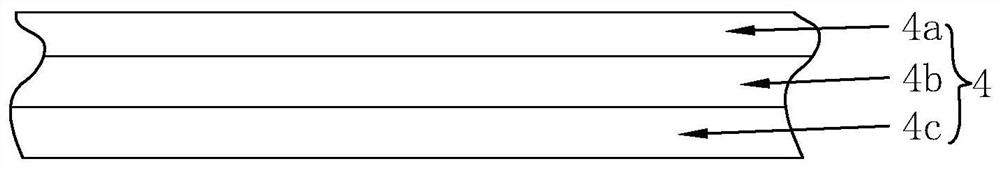

[0036] A fluorine-lined pipe flue gas heating system, comprising a pressure reducer 1, a heat exchanger 2 and a chimney 3, a heat exchanger 2, and the heat exchanger 2 includes a shell 2a, and the upper and lower ends of the shell 2a are respectively provided with air intakes The upper and lower ends of the casing 2a are provided with tube sheets 2d respectively, a heat exchange chamber 2e is formed between the two tube sheets 2d, and a number of heat exchange chambers are inserted between the two tube sheets 2d. Pipe 2f, the side wall of the shell 2a is provided with a flue gas inlet pipe 2g and a flue gas outlet pipe 2h that communicate with the heat exchange chamber 2e; the heat exchange pipe 2f, the shell 2a and the tube sheet 2d are all made of carbon steel. The outer wall of the heat exchange tube 2f, the inner wall of the shell 2a and the two side walls of the plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com