Device and method for testing lip adhesion of tipping paper for cigarettes

A technology of tipping paper and testing device for cigarettes, which is applied in the field of analysis and detection, and can solve problems such as large differences in detection and judgment results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

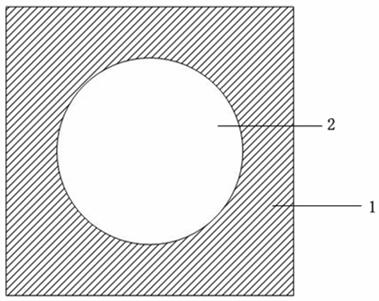

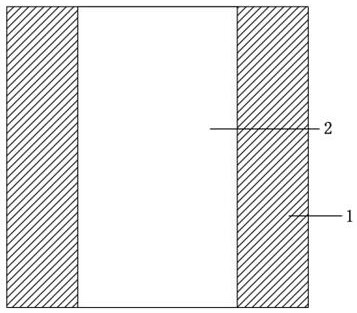

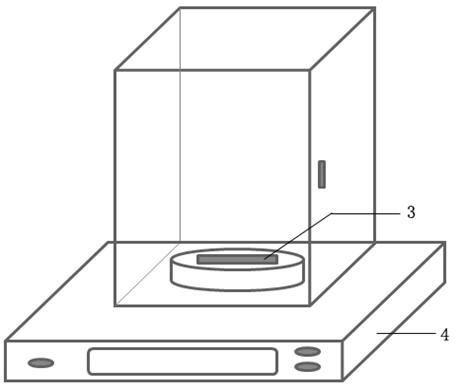

[0046] Such as Figure 1~4 As shown, a test device for the stickiness of tipping paper for cigarettes includes a stainless steel body 1 and a balance 4; the bottom surface of the stainless steel body 1 is horizontal, and the stainless steel body 1 is provided with a through groove 2 as an artificial saliva groove; The axial direction of the groove 2 is perpendicular to the horizontal plane.

Embodiment 2

[0048] Such as Figure 1~4 As shown, a test device for the stickiness of tipping paper for cigarettes includes a stainless steel body 1 and a balance 4; the bottom surface of the stainless steel body 1 is horizontal, and the stainless steel body 1 is provided with a through groove 2 as an artificial saliva groove; The axial direction of the groove 2 is perpendicular to the horizontal plane. The stainless steel body 1 is in the shape of a cube. The length of one side of the stainless steel body is 15-30mm, and the mass is greater than or equal to 500g. The through groove 2 is cylindrical and has a diameter of 5-20mm. The through groove 2 is located at the center of the stainless steel body 1 . Balance 4 is an analytical balance with a sensitivity not less than 0.1 mg.

Embodiment 3

[0050] A method for testing the stickiness of tipping paper for cigarettes, using the test device for stickiness of tipping paper for cigarettes described in Example 1, comprising the steps of:

[0051] Step (1), cutting the length of the tipping paper for cigarettes;

[0052] Step (2), weighing the tipping paper to be tested on a balance;

[0053] Step (3), placing the stainless steel body horizontally on the printing surface of the tipping paper to be tested;

[0054]Step (4), placing a certain amount of artificial saliva in the stainless steel body artificial saliva tank;

[0055] Step (5), pull the stainless steel body along the long side at a constant speed so that the tipping paper to be tested fully contacts and penetrates the artificial saliva until the stainless steel body is separated from the tipping paper, takes out the tipping paper to be tested, and absorbs the excess artificial saliva with absorbent paper Walk;

[0056] Step (6), immediately weighing the tipp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com