Preparation method and application of sulfydryl modified graphene oxide nanosheet/geopolymer composite material

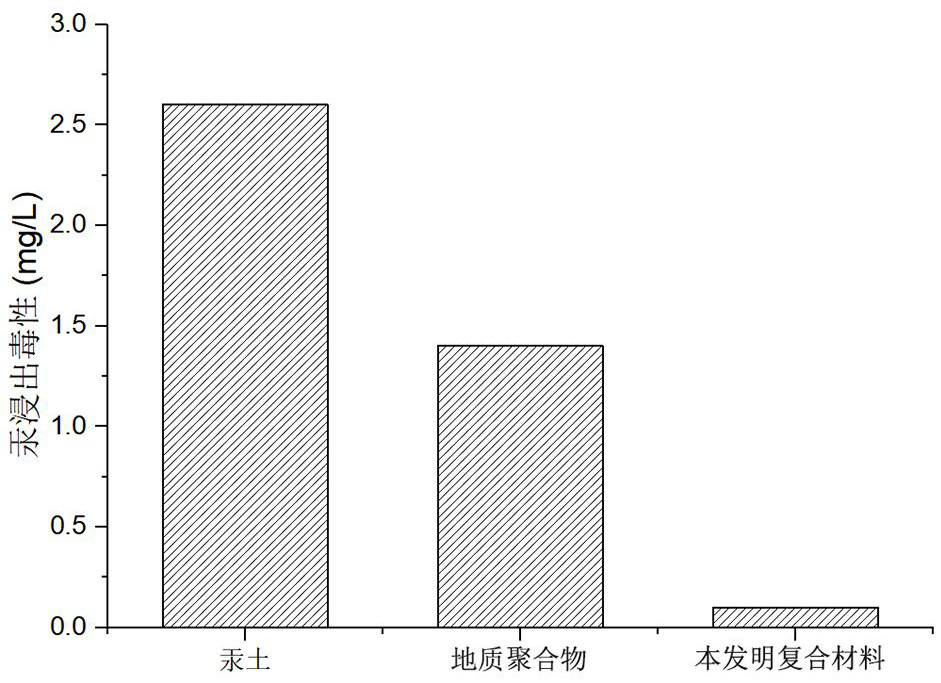

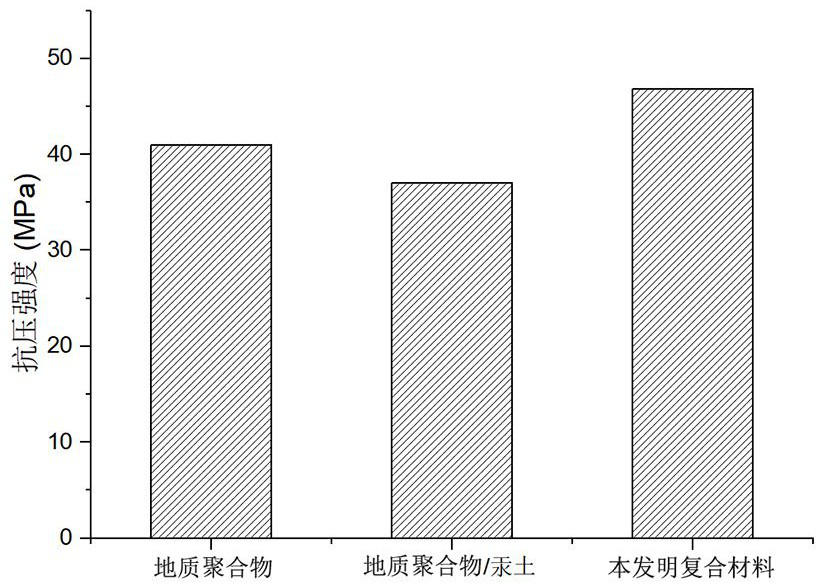

A technology of geopolymers and composite materials, which is applied in the field of preparation of mercapto-modified graphene oxide nanosheets/geopolymer composites, can solve the problems of harmless treatment of pollution, re-dissolution, etc., and achieve low leaching rate, good The effect of the adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

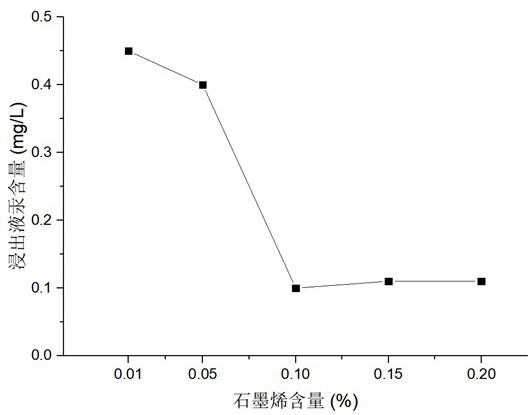

Embodiment 1

[0029] Take 0.2g of graphene oxide, control the ratio of graphene oxide and KH 590 to 100mg: 1ml, take 2ml of KH590, add appropriate amount of ethanol, then add acetic acid to adjust the pH to 5, react at 78°C for 6 hours, take it out, Centrifuge at 10000r / min for 6 minutes, then wash with ethanol repeatedly 5 times to remove unreacted KH 590. Then add a mixed solution of an appropriate amount of ethanol and water (ethanol: water = 1: 1), then take out 3 parts of 2ml mercapto-modified graphene oxide nanosheet mixed solution and put it in a vacuum drying oven to dry, by the mass of the obtained pure solid, calculate The concentration of the prepared mercapto-modified graphene oxide nanosheets (measured three times and averaged) was 10 mg / ml. Weigh 0.6ml of mercapto-modified graphene oxide nanosheet solution, dissolve it in 10ml of water, and disperse it ultrasonically for 30 minutes. Control the ratio of the mass of mercapto-modified graphene oxide nanosheets to the mass of mer...

Embodiment 2

[0031]Take 0.2g of graphene oxide, control the ratio of graphene oxide and KH 590 to 100mg: 1ml, take 2ml of KH590, add an appropriate amount of ethanol, then add acetic acid to adjust the pH to 5, react at 78°C for 6 hours, take it out, Centrifuge at 10000r / min for 6 minutes, then wash with ethanol repeatedly 5 times to remove unreacted KH 590. Then add a small amount of mixed solution of ethanol and water (ethanol: water = 1: 1), then take out 3 parts of 2ml KH 590 / GO mixed solution and dry it in a vacuum oven, and calculate the prepared mercapto group by the mass of the obtained pure solid The concentration of the modified graphene oxide nanosheets (measured three times and averaged) was 10 mg / ml. Weigh 0.4ml of mercapto-modified graphene oxide nanosheet solution and dissolve it in 2ml of water, ultrasonically disperse for 30 minutes, control the ratio of the mass of mercapto-modified graphene oxide nanosheets to the mass of mercury soil to be 1:1000, that is, add 4g of mer...

Embodiment 3

[0033] Take 0.2g of graphene oxide, control the ratio of graphene oxide and KH 590 to 100mg: 1ml, take 2ml of KH590, add an appropriate amount of ethanol, then add acetic acid to adjust the pH to 5, react at 78°C for 6 hours, take it out, Centrifuge at 10000r / min for 6 minutes, then wash with ethanol repeatedly 5 times to remove unreacted KH 590. Then add a small amount of mixed solution of ethanol and water (ethanol: water = 1: 1), then take out 3 parts of 2ml KH 590 / GO mixed solution and dry it in a vacuum oven, and calculate the prepared mercapto group by the mass of the obtained pure solid The concentration of the modified graphene oxide nanosheets (measured three times and averaged) was 10 mg / ml. Weigh 4ml of mercapto-modified graphene oxide nanosheet solution and dissolve it in 5ml of water, ultrasonically disperse for 30 minutes, control the ratio of the mass of mercapto-modified graphene oxide nanosheets to the mass of mercury soil to be 1:200, that is, add 8g of mercu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com