Preparation method and application of double-metal cyanide catalyst

A double metal cyanide and double metal catalyst technology, applied in the field of catalytic systems, can solve the problems of reducing the amount of organic ligands used, achieve high catalytic activity and selectivity, wide applicability, and reduce consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Preparation of DMC-1 using ethylene glycol dimethyl ether (DME) as extract:

[0056] (a) At a constant temperature of 30°C, 5g K 3 [Co(CN) 6 ] and a mixed solution of 30ml deionized water (the concentration of double metal cyanide is 0.5mol / L) dropwise added to the mixture made of 10g ZnCl 2 , 20ml of DME and 20ml of deionized water (the concentration of the metal salt is 1.84mol / L), after the dropwise addition is completed, continue to stir and react at a constant temperature of 30°C for 2h. The catalyst filter cake was obtained by filtration.

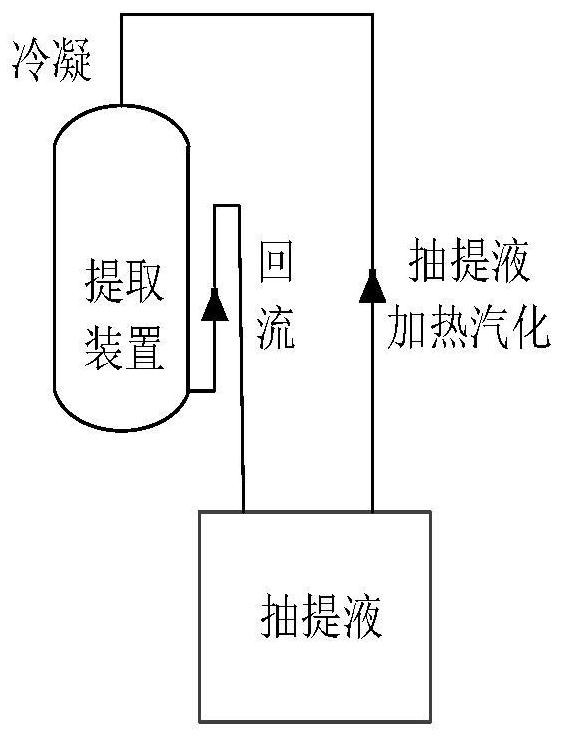

[0057] (b) Put the filter cake in the extraction device and use 100mL DME as the extraction liquid. After the DME is heated and vaporized, it will be condensed and dropped into the extraction device to wash the double metal cyanide catalyst, and then return to the container for storing the extraction liquid. Within, extract for 1h. Then, the extracted and washed precipitate was dried and pulverized to obtain 2.8 g of DMC-1....

Embodiment 2

[0060] Preparation of DMC-2 using methanol (MeOH) as organic ligand:

[0061] The preparation process of DMC-2 is the same as that of Example 1, except that the equal volume of DME is replaced by MeOH to obtain 2.6g DMC-2, the structural formula of which is: Zn 3 [Co(CN) 6 ] 2 1.35MeOH 1.21ZnCl 2 0.18H 2 O.

Embodiment 3

[0063] Preparation of DMC-3 using ethanol (EtOH) as organic ligand:

[0064] The DMC-3 preparation process is the same as in Example 1, except that the equal volume of DME is replaced by EtOH to obtain 2.6g DMC-3, and the structural formula is: Zn 3 [Co(CN) 6 ] 2 1.66EtOH 1.17ZnCl 2 0.22H 2 O.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com