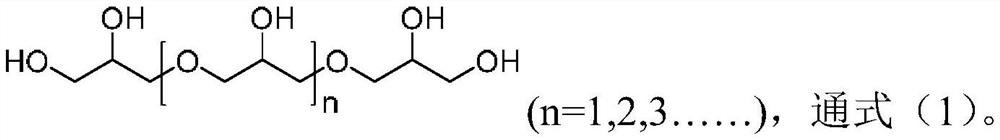

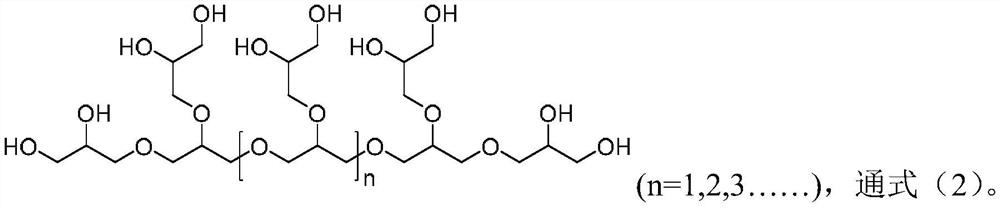

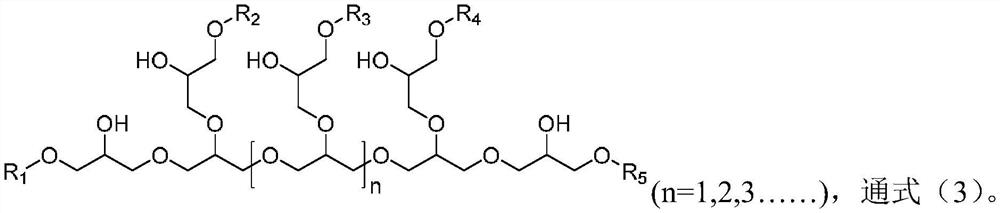

Hyperbranched polyglycerol ester bio-based plasticizer as well as preparation method and application thereof

A technology of polymerizing glycerin and bio-based, applied in the field of plastic additives, can solve the problems of non-additive, non-bio-based plasticizers, white pollution, etc., and achieve the effect of simple operation, reduced production cost, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In a 500ml four-neck flask, add 230g of anhydrous glycerin and K 2 CO 3 0.23g, install the mechanical stirring device, feed N 2 Protect, insert a thermometer and a distillation condenser, stir and heat up, the temperature rises slowly between 100-220°C to start the polymerization reaction, when the condenser receives water in the bottle and generates 36g of reactant, the hydroxyl value is 1021mgKOH / g, and the degree of polymerization is at this time 5. Control the temperature of the polymerized glycerin at 100-120°C, add 31g of glycidol dropwise, and keep it warm for 2 hours after the dropping, to obtain 225g of light yellow viscous liquid hyperbranched polymerized glycerol, with a yield of 97.8% relative to glycerol.

Embodiment 2

[0038] 100 kilograms of hyperbranched polyglycerol prepared according to the process of Example 1 and 20 kilograms of glacial acetic acid, 0.5 kilograms of phosphoric acid were mixed and stirred, heated and refluxed for esterification reaction, rectified water in the reflux process, and the acid value of the esterified product was determined to be less than or equal to 0.5 mgKOH / g was the reaction end point. After it was cooled to room temperature, it was loaded into barrels and weighed to obtain 110.2 kg of hyperbranched polyglyceride bio-based plasticizer with a mass yield of 91.8%.

Embodiment 3

[0040] 100 kilograms of hyperbranched polyglycerol prepared according to the process of Example 1 and 20 kilograms of propionic acid, mixed with 0.5 kilograms of phosphoric acid, heated and refluxed for esterification reaction, rectified water during the reflux process, and the acid value of the esterified product was determined to be less than or equal to 0.5 mgKOH / g is the reaction end point. After it is cooled to room temperature, it is loaded into barrels and weighed to obtain 112.6 kg of hyperbranched polyglyceride bio-based plasticizer with a mass yield of 93.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com