Method for extracting cinnamomum longepaniculatum oil

A technology of camphor oil and camphor leaves, applied in the directions of essential oil/fragrance, fat oil/fat production, fat oil/fat refining, etc., can solve the problems of low extraction yield, waste of resources, low oil yield, etc. The effect of obtaining rate, ensuring purity and avoiding residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

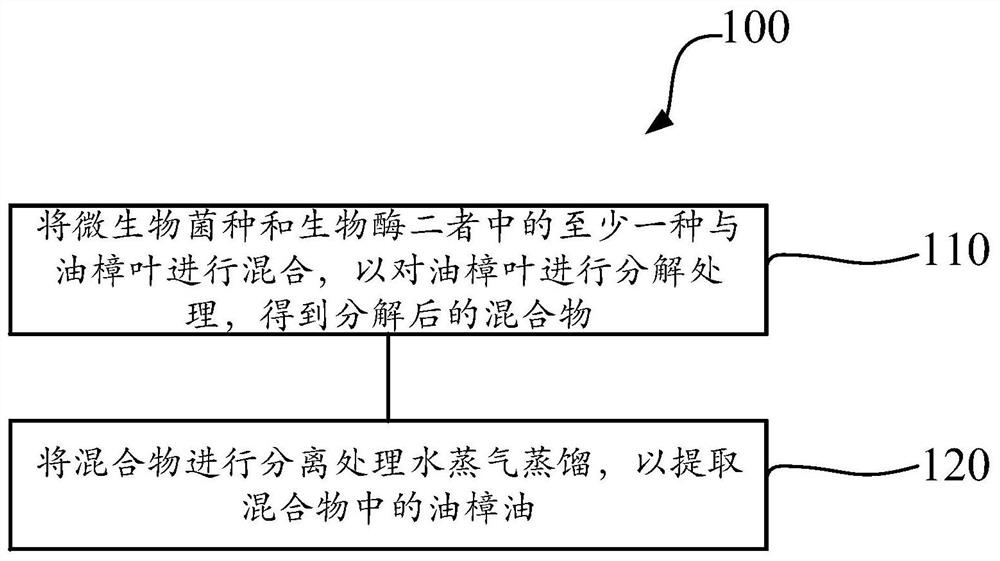

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Weigh 1000g of fresh leaves of Camphor oleifera and 5g of Bacillus strains and mix them, fermented at PH=6 and temperature of 30°C for 48h, and then subjected the mixture obtained after the fermentation to steam distillation for 2h , to obtain 32g of camphor oil. Compared with the existing batch distillation extraction method (general yield is 2%, distillation time generally takes 4h), the yield of camphor oil extracted by the method of this embodiment can be increased by about 60%, and the distillation time can be shortened by 2h.

Embodiment 2

[0029]Embodiment 2: Weigh 1000g of fresh leaves of Camphor oleifera and 7g of lactic acid bacteria strains and mix the two, fermented for 60h at PH=6.5 and temperature of 28°C, then the mixture obtained after the fermentation was subjected to steam distillation for 2h, 30 g of camphor oil was obtained. Compared with the existing batch distillation extraction method (general yield is 2%, distillation time generally takes 4h), the yield of camphor oil extracted by the method of this embodiment can be increased by about 50%, and the distillation time can be shortened by 2h.

Embodiment 3

[0030] Embodiment 3: Weigh 1000g of fresh leaves of Camphor oleifera and 6g of Bacillus megaterium strains and mix the two, fermented for 72h at PH=5.5 and temperature of 32°C, and then the mixture obtained after the fermentation was subjected to steam distillation 2h, 31 g of camphor oil was obtained. Compared with the existing batch distillation extraction method (general yield is 2%, distillation time generally takes 4h), the yield of camphor oil extracted by the method of this embodiment can be increased by about 55%, and the distillation time can be shortened by 2h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com