Direct-bonded lamination for improved image clarity in optical devices

A direct bonding and bonding technology, applied in optical components, optics, instruments, etc., can solve the problems of complex harmful effects of adhesive layers, and achieve the effect of eliminating dark line of sight, high image brightness, and less light scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

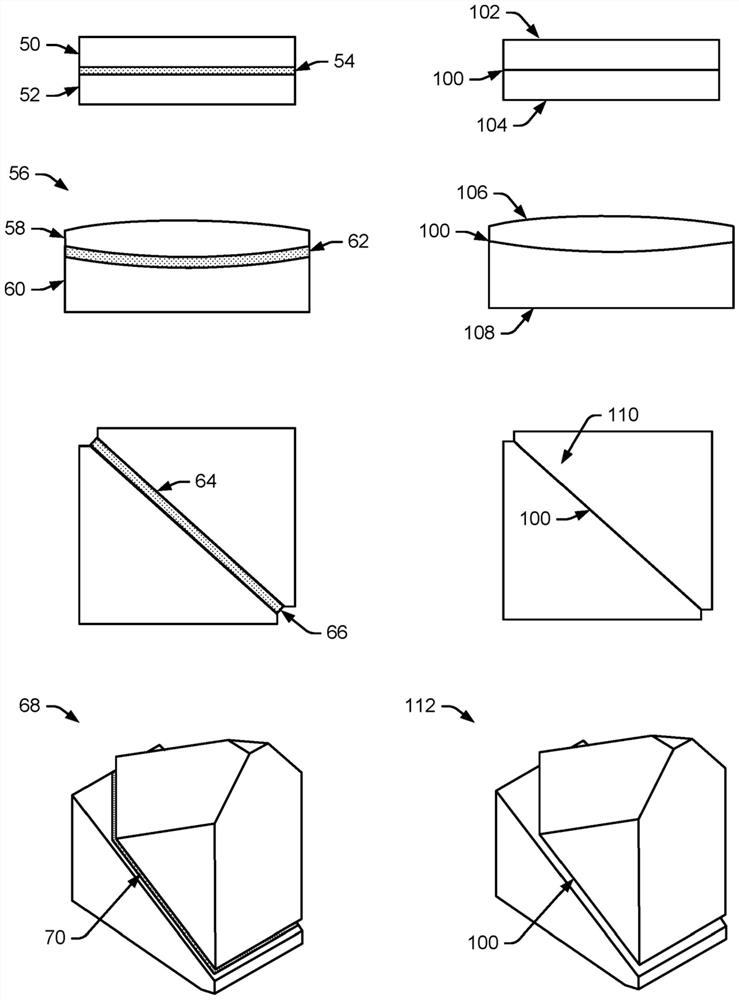

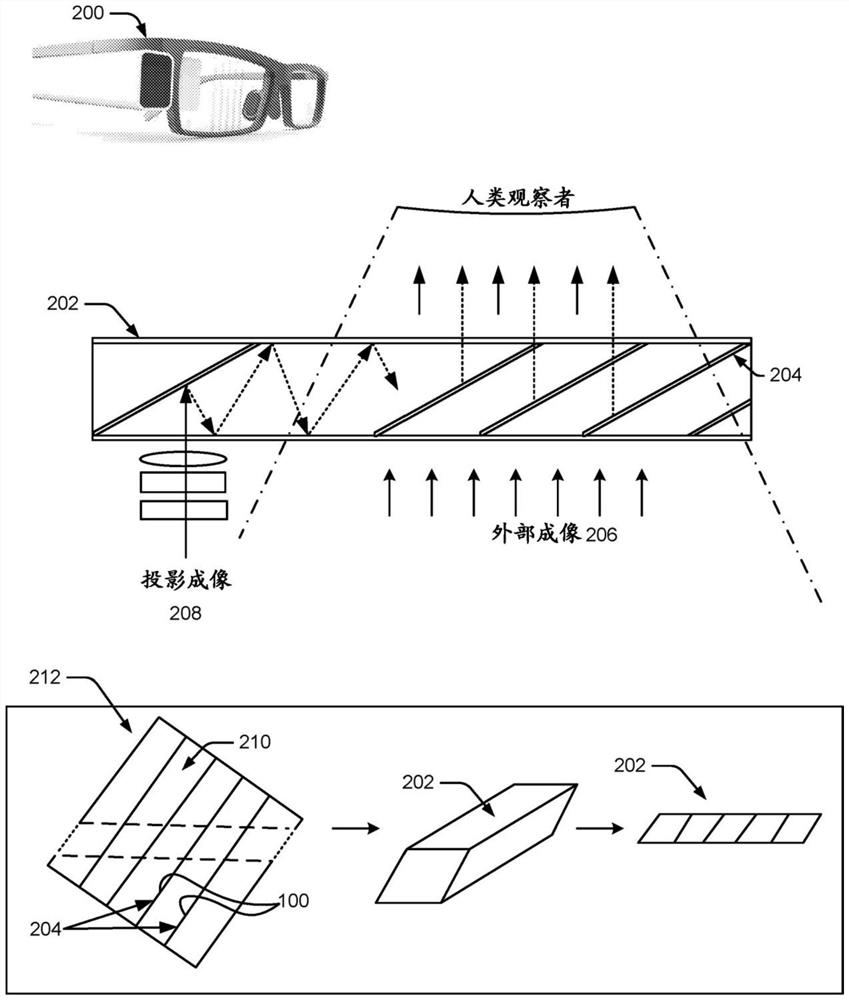

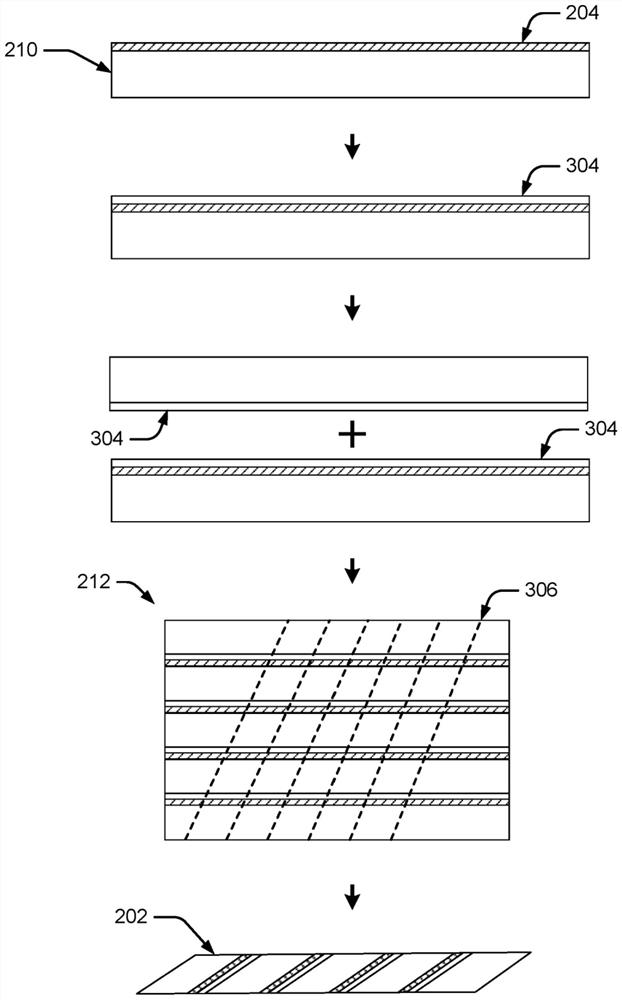

[0012] The present disclosure describes direct bond lamination for improved clarity in optical devices. In one implementation, the example direct bonding technique aims to minimize or eliminate optical adhesives and glues between optical layers that can lead to loss of image quality in the optical device.

[0013] In one implementation, for optical precision, bonding or lamination is done using direct oxide bonding between surfaces (such as silicon oxide to silicon oxide bonding) or direct bonding between surfaces and other semiconductor non-metallic combinations. An optical layer made of glass or other material. Besides silicon dioxide, other materials can also be used for direct bonding, such as silicon nitride (Si 3 N 4 ), silicon oxynitride (SiON), silicon carbonitride (SiCN) and other compounds. Elimination of a separate adhesive or adhesive layer between the surfaces of the optical layer improves optical performance, such as higher fidelity of light transmission. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com