Ceramic raw material stirring device

A technology of a stirring device and ceramic raw materials, which is applied in the field of ceramic processing, can solve the problems of affecting the production rhythm, increasing manual operations, and low production efficiency, and achieving the effects of ensuring the quality of ceramic products, reducing manual operations, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

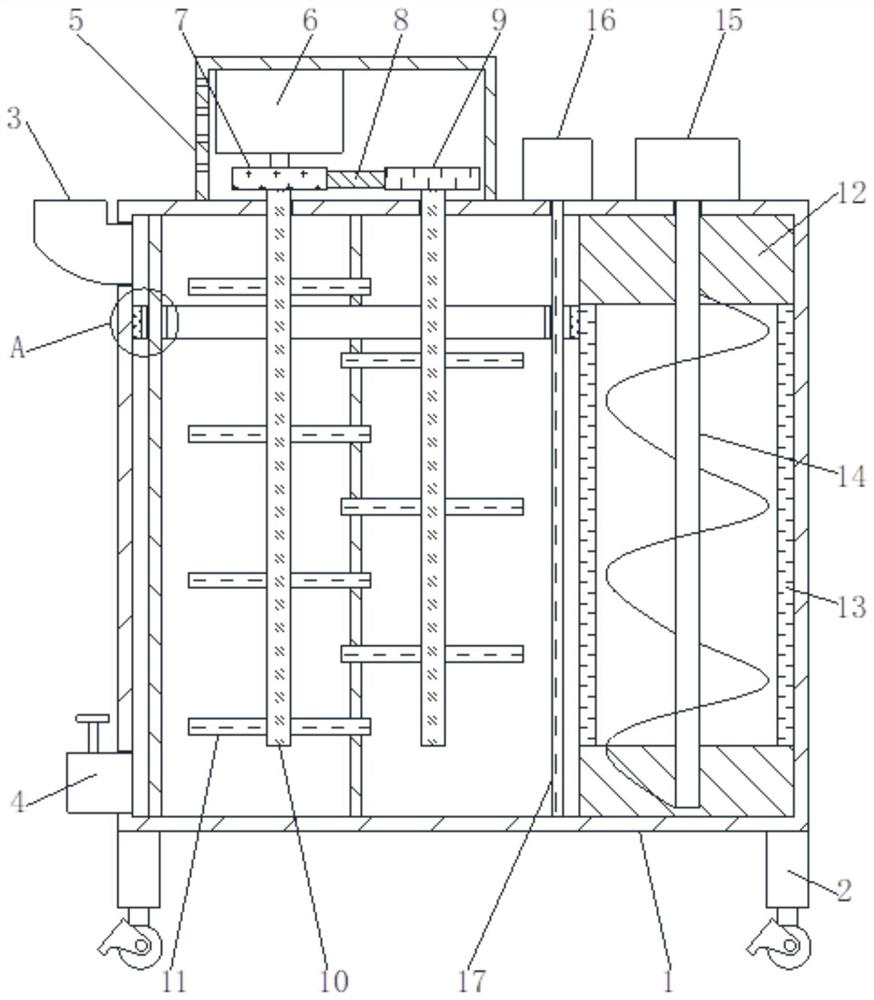

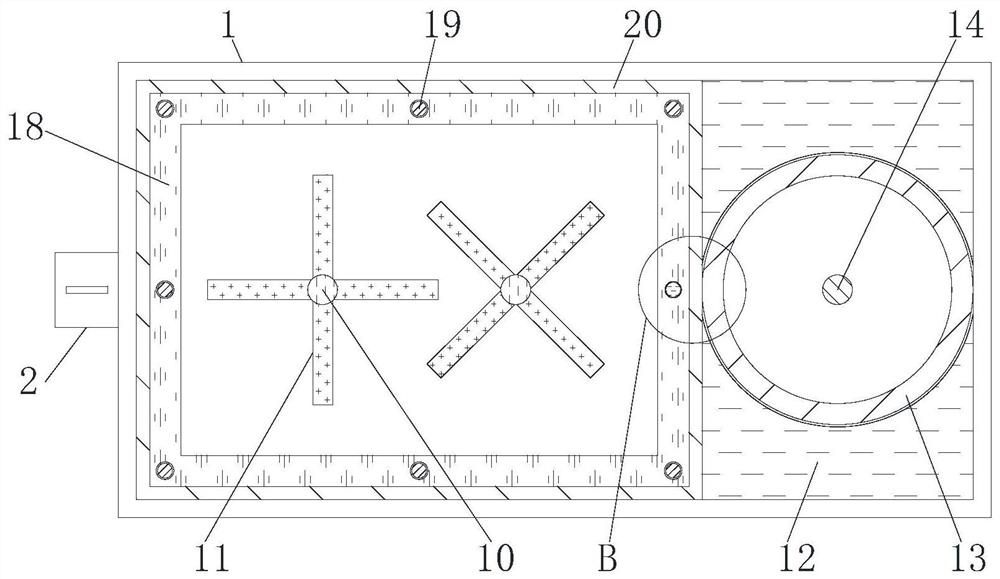

[0025] Such as Figure 1 to Figure 5 As shown, a stirring device for ceramic raw materials includes a shell 1, a stirring mechanism and a cleaning mechanism. The inner cavity of the shell 1 is provided with a stirring chamber, the stirring mechanism is arranged in the middle of the stirring chamber, and the cleaning mechanism is arranged between the shell 1 and the stirring mechanism. between;

[0026] Described cleaning mechanism comprises the 3rd electric motor 16, sliding plate 18, limit post 19 and screw rod 17, and several limit posts 19 are vertically installed in the inner cavity of housing 1, and the upper and lower ends of limit post 19 are connected with housing respectively. 1. The bottom surface of the inner cavity is fixedly connected to the top surface. The sliding plate 18 is set on the limit post 19. The screw rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com