Expansion type oil removal method for steel plate with multiple pores in surface

An expansive, multi-porous technology, which is applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve problems such as low processing efficiency, affecting processing and use, and difficult to cover oil stains. Oil effect, the effect of improving the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

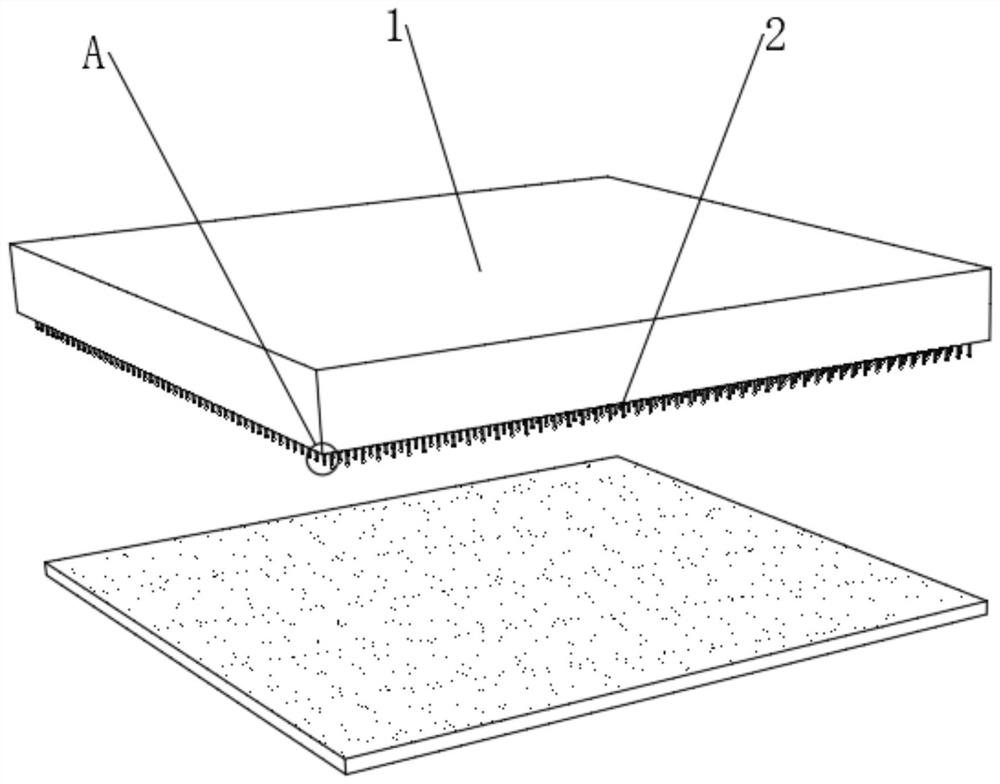

[0044] see figure 1 , an expansive degreasing method for a porous steel plate, comprising the following steps:

[0045] S1. Heat the steel plate at 40-60°C in a closed space;

[0046] S2. First use a steel brush to rub the surface of the steel plate back and forth to force the pasty oil to loosen;

[0047] S3, then use the brush roller wrapped with oil-absorbing felt to roll back and forth on the surface of the steel plate to absorb oil for 3-5 times until there is no obvious oil stain on the surface;

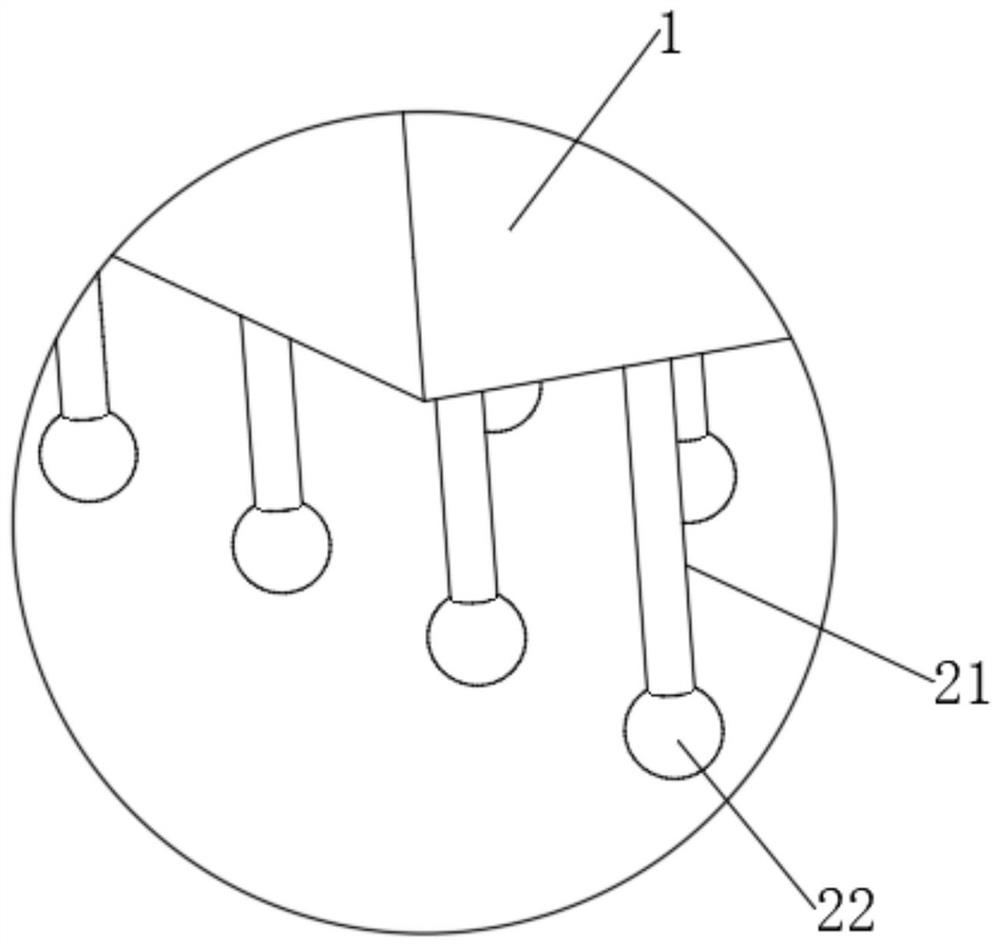

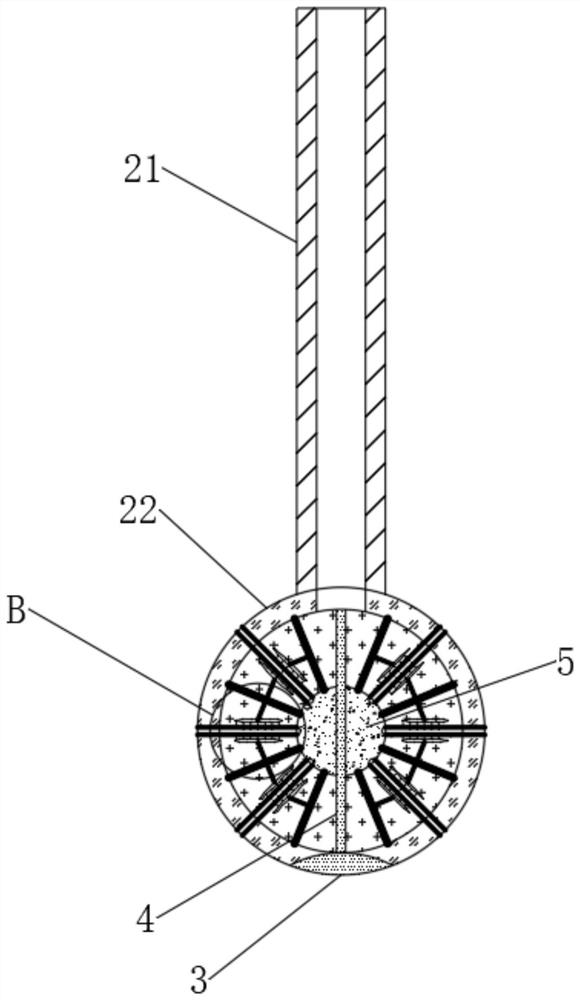

[0048] S4. Attach the degreasing box 1 to the surface of the steel plate and squeeze it slightly, forcing the expanding oil-absorbing tentacles 2 covered and distributed on the degreasing box 1 to fully enter the pores on the surface of the steel plate to trigger the expansion and oil-absorbing action;

[0049] S5. Finally, use high-pressure water to wash the surface of the steel plate, and recycle the oil stains on the expanded oil-absorbing tentacles 2 and the oil-absorbing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com