Method for producing high-purity ammonium chloride from industrial-grade ammonium chloride

An ammonium chloride, industrial-grade technology, applied in the field of purification of industrial-grade ammonium chloride, can solve problems such as being unable to be used directly and failing to meet requirements, and achieve the effects of reducing environmental protection pressure, reducing the generation of by-products, and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

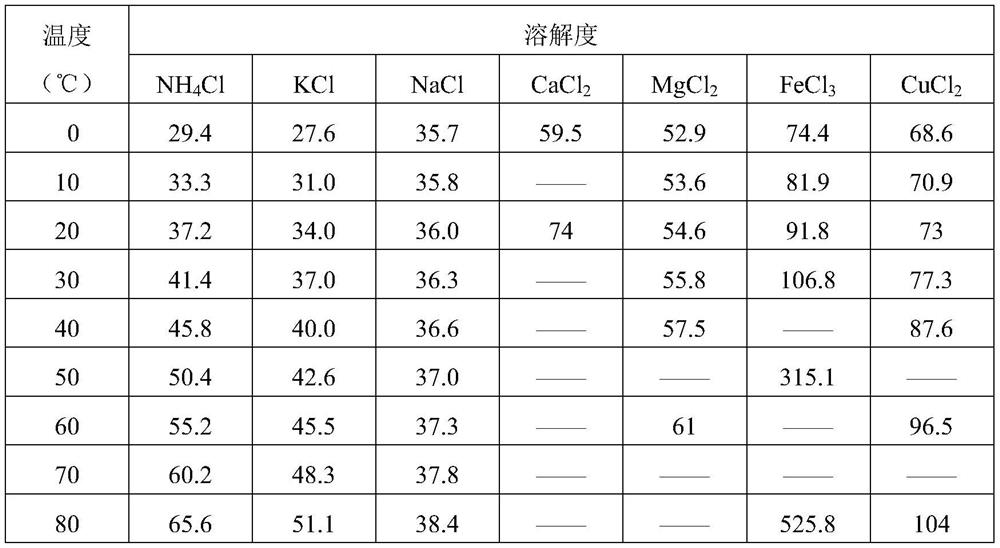

[0045] (1) Take 800g of deionized water, weigh 524.8g of industrial grade ammonium chloride according to the solubility of ammonium chloride at 80°C, place the beaker containing deionized water and ammonium chloride in a constant temperature water bath and heat it to 80°C ℃, and kept stirring to completely dissolve the ammonium chloride to obtain a saturated ammonium chloride solution;

[0046] (2) Place the saturated ammonium chloride solution at room temperature and slowly cool down to crystallize the ammonium chloride. When the temperature reaches room temperature, put it into a low-temperature constant temperature water bath to continue crystallization until the temperature reaches 5° C.;

[0047] (3) The ammonium chloride crystallized in step (2) is kept at the crystallization temperature and filtered through a sand core funnel to obtain ammonium chloride crystals, and the ammonium chloride mother liquor obtained by filtering is collected for processing;

[0048] (4) The ...

Embodiment 2

[0053] The steps are the same as in Example 1, except that the washing time in steps (4) and (6) is 3 minutes.

Embodiment 3

[0055] The steps are the same as in Example 1, except that the washing time in steps (4) and (6) is 5 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com