Preparation device of multilayer microstructure fiber based on near-field electrospinning direct writing

A technology of electrospinning direct writing and preparation device, which is applied in fiber processing, textile and papermaking, filament/thread forming and other directions, can solve the problems of inability to three-dimensional forming and poor technical precision, and achieve shortening curing time, improving precision, guaranteeing The effect of precision and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

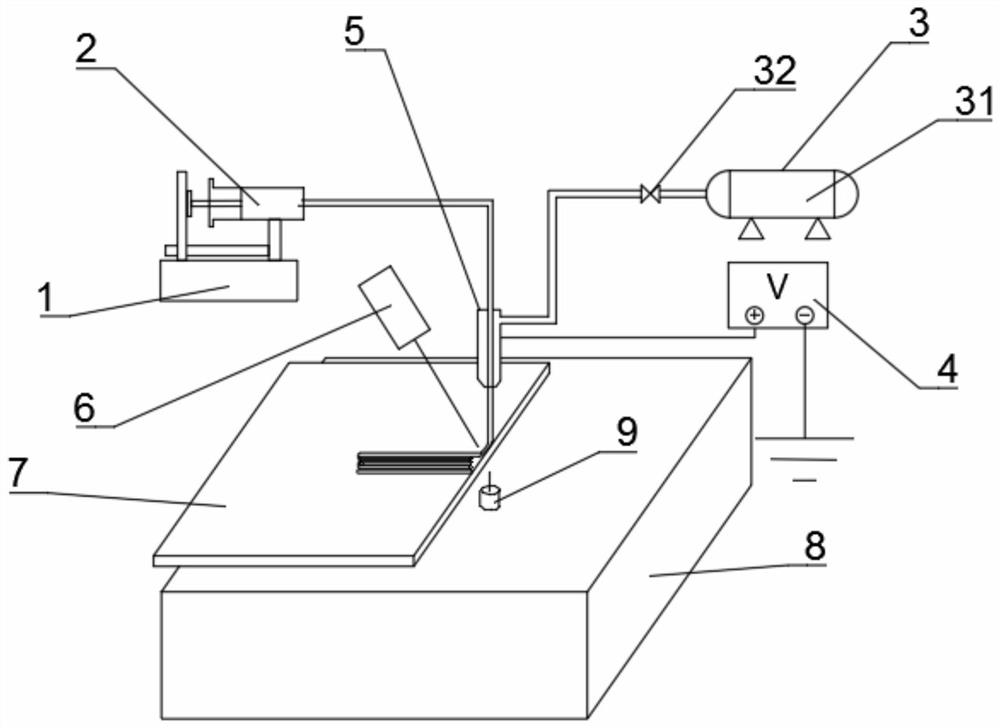

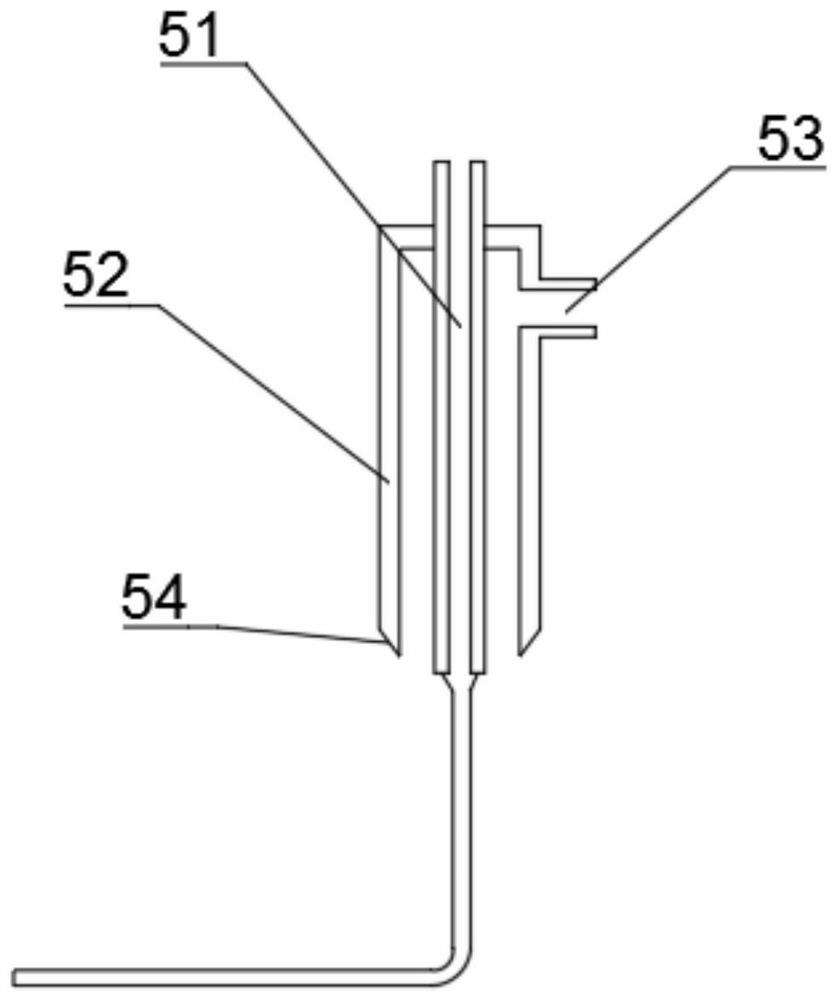

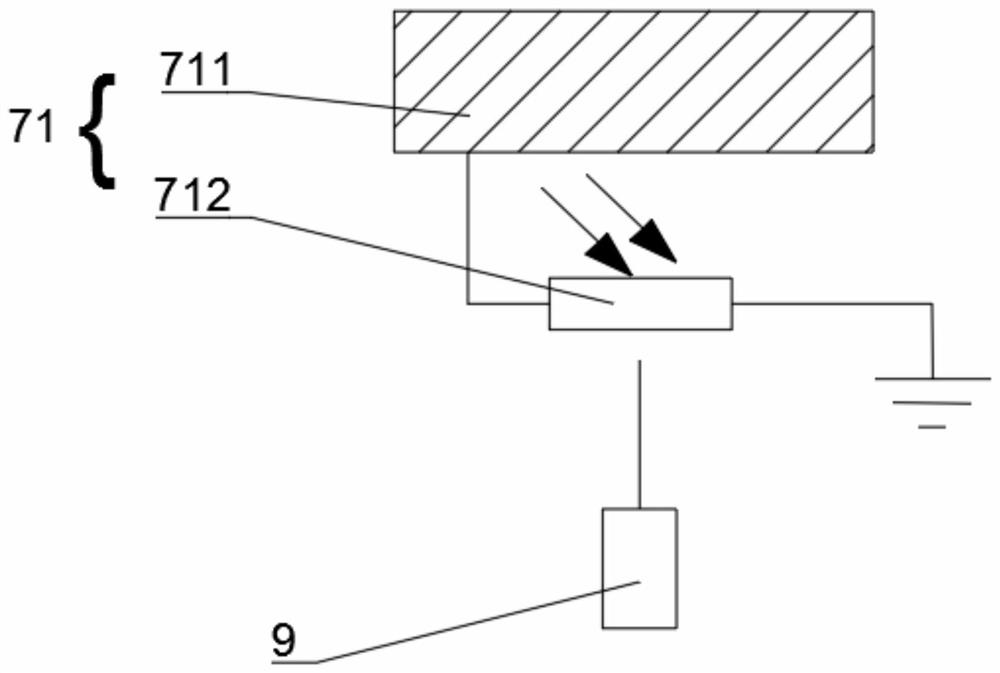

[0031] see Figure 1-6 In this embodiment, a preparation device for multilayer microstructure fibers based on near-field electrospinning direct writing, including a syringe pump 1, an injection needle tube 2, an electrospinning needle 5, a high-voltage power supply 4, a collecting plate 7, a displacement control platform 8, The focused irradiation light source 9, the sheath gas device 3 and the focused heating light source 6, the injection needle 2 is set on the syringe pump 1, the injection needle 2 is connected with the electrospinning needle 5 through the catheter, and the syringe pump 1 transports the solution in the injection needle 2 to the electrospinning needle. The spinning needle head 5 and the collecting plate 7 are located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com