A Method for Measuring the Resistivity of Metallic Iron under Ultra-High Voltage

An ultra-high voltage, resistivity technology, applied in the measurement of resistance/reactance/impedance, measurement of electrical variables, measurement of heat, etc., can solve the problem of large temperature gradient, inability to test sheet samples, and large errors in resistivity measurement results of pure metals, etc. problems, to achieve the effect of accurate measured resistivity, avoid direct contact, and improve measurement accuracy

Active Publication Date: 2021-10-01

INST OF GEOCHEM CHINESE ACADEMY OF SCI

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The technical problem to be solved by the present invention is: to provide a method for measuring the resistivity of metallic iron under ultra-high pressure, so as to solve the problem that under ultra-high voltage conditions, the measurement results of resistivity of pure metal have large errors and large temperature gradients, making it impossible to test flakes. Samples and other technical issues

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0056] Recording current and potential of embodiment 1

[0057]

Embodiment 2

[0058] Recording current and potential of embodiment 2

[0059]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

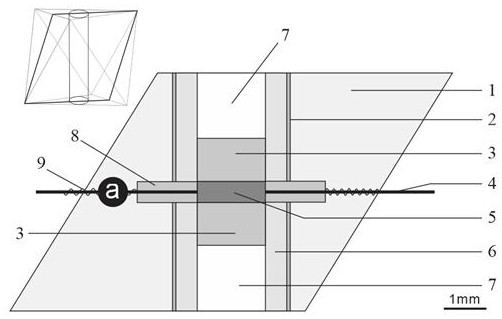

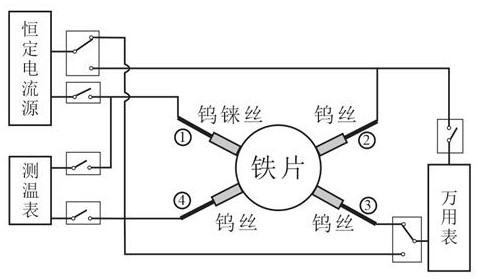

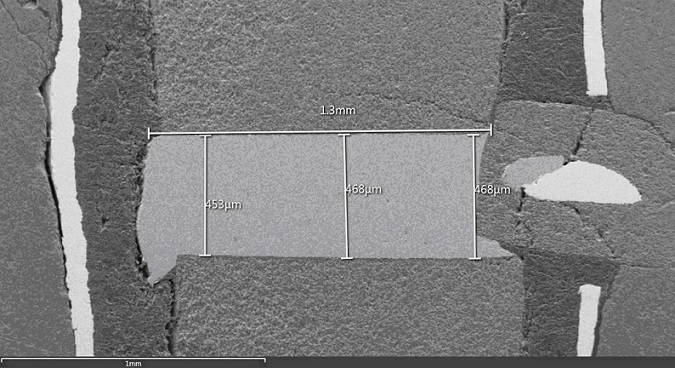

The invention discloses a method for measuring the resistivity of metal iron under ultra-high pressure, which includes: using a laser cutting machine to process high-purity iron sheets and rhenium sheets into circular samples and rectangular parts respectively; using the rhenium sheet as a heater, And assemble the circular iron piece, three tungsten wires and one tungsten-rhenium alloy wire in the ultra-high pressure test device; place the test assembly block in the six-sided top press, load it to the specified pressure and temperature, and test the sample The resistivity is measured and recorded using the four-probe van der Pauw principle; after heating and data recording, the pressure is unloaded; after the circular iron sample is taken out, it is fixed with epoxy resin, and then cut, ground and polished to form a circular Measure the thickness of the longitudinal section of the iron sheet, and calculate the resistivity value of the metal iron sheet under different temperature and pressure conditions by using the Vanderbilt measurement method formula; solve the problem of large temperature gradient and inaccurate temperature measurement in the prior art, and the measurement wires are in contact with each other , the problem of too many resistivity calculation parameters and large errors.

Description

technical field [0001] The invention belongs to the field of testing devices, in particular to a method for measuring the resistivity of metallic iron under ultra-high voltage. Background technique [0002] The resistivity of common metals, such as iron, nickel, copper, aluminum, etc. is very low, about ten to the negative eighth power and negative seven power ohms per meter. Accurately measuring the resistivity of these metals is particularly difficult. At atmospheric pressure, there are already many commercial metal resistivity measurement platforms and tools that are widely used in laboratories and industries. However, there is a lack of methods for measuring the resistivity of metals under ultra-high pressure and high temperature conditions. Because in the high-temperature and high-pressure generating device, the volume of the sample to be tested is limited, the arrangement of electrode wires is complicated, and it faces the risk of high failure rate under extreme temp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01R27/08G01B21/08G01K7/02

CPCG01B21/08G01K7/02G01R27/08

Inventor 尹远王林翟双猛

Owner INST OF GEOCHEM CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com