Extraction and purification method of cannabidiol

A purification method, the technology of cannabidiol, applied in the field of purification, can solve problems such as environmental hazards, product safety impacts, solvents cannot be completely removed, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

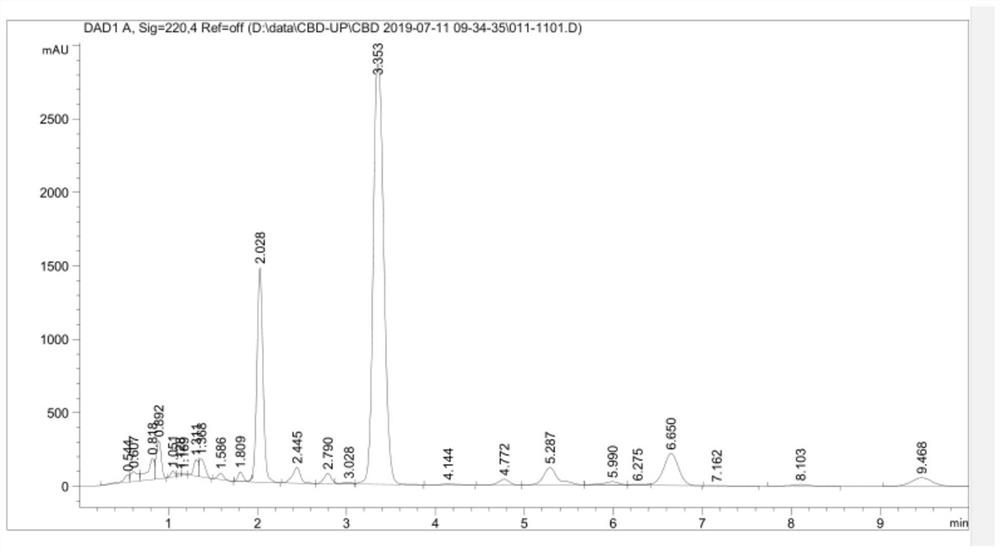

Image

Examples

Embodiment 1

[0053] The industrial hemp leaf material is crushed to 40 mesh, dried, weighed 100 grams, extracted in 100% ethanol, the extraction temperature is 60 ° C, the ratio of material to liquid is 1:5, the extract is collected after extraction once, and the residue is Add a new batch of solvent in the same amount as the previous one, repeat the extraction once, combine the extracts, remove the solvent from the extracts under reduced pressure, and place them in an oven at 105°C to dry to remove residual solvents. At this point the cannabidiol content in the extract was 10.1%.

[0054] The dried extract was washed with 5% sodium carbonate solution, the ratio of solid to liquid was 1:10, washed three times, and the precipitate was collected and dried in an oven at 105°C to remove residual solvent. The dried extract was dissolved in acetonitrile, an organic solvent, with a solid-to-liquid ratio of 1:10 (g / mL), dissolved five times, and the solutions were collected and combined five times...

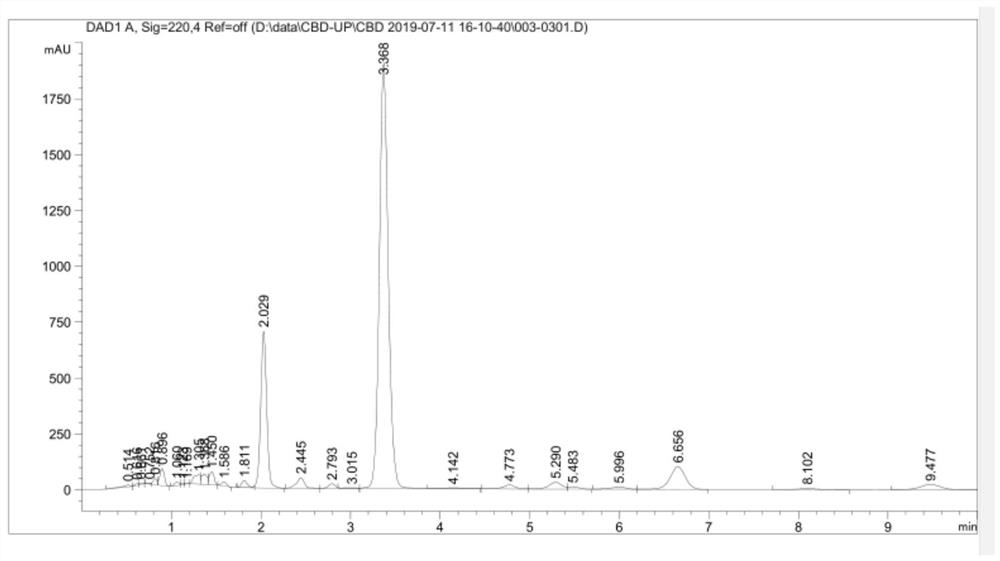

Embodiment 2

[0058] The industrial hemp leaf material is crushed to 40 mesh, dried, weighed 100 grams, extracted in 100% ethanol, the extraction temperature is 60 ° C, the ratio of material to liquid is 1:5, the extract is collected after extraction once, and the residue is Add a new batch of solvent in the same amount as the previous one, repeat the extraction once, combine the extracts, remove the solvent from the extracts under reduced pressure, and place them in an oven at 105°C to dry to remove residual solvents. At this point the cannabidiol content in the extract was 12.1%.

[0059] The dried extract was washed with 15% sodium carbonate solution, the ratio of solid to liquid was 1:10, washed five times, and the precipitate was collected and dried in an oven at 105°C to remove residual solvent. The dried extract was dissolved in acetonitrile, an organic solvent, with a solid-to-liquid ratio of 1:10 (g / mL), dissolved five times, and the solutions were collected and combined five times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com