High-wear-resistance all-steel truck radical tire tread rubber

A radial tire and tread rubber technology, which is applied in special tires, tire parts, transportation and packaging, can solve the problems of physical and mechanical performance degradation, reduced tire service life, poor self-reinforcement of butadiene rubber, etc., and achieve excellent Abrasion performance and service life extension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

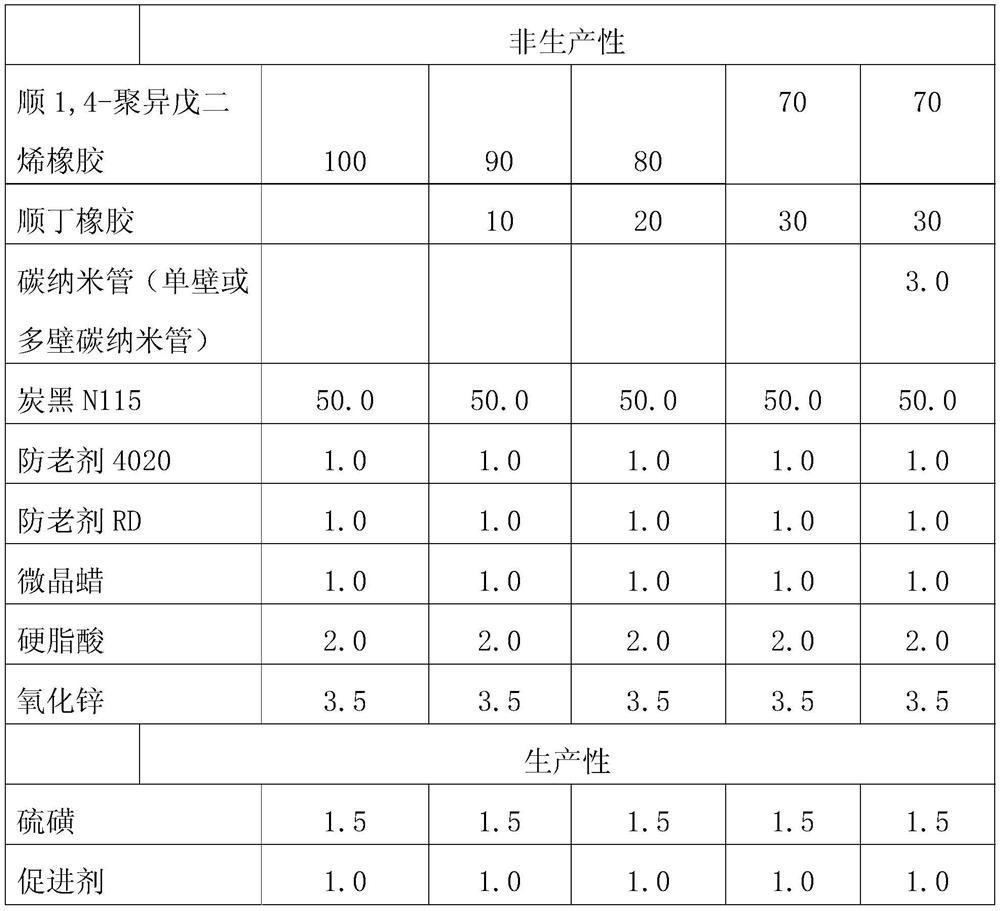

[0019]The tread rubber with the composition specified in Table 1 was prepared in the BR Banbury internal mixer. The preparation process adopted two separate feeding and mixing stages, namely, a non-productive mixing stage and a productive mixing stage. In the non-productive stage, mixing is carried out for about 2-3 minutes, until the rubber temperature reaches 160°C, which is complete. The mixing time in the productive stage is the time for the rubber temperature to reach 115°C.

[0020]The tread rubber is referred to as sample a, sample b, sample c, sample d, and sample e here. Sample a is used here as a control sample, that is, the optimal amount of filler is not used in the filler system.

[0021]All samples were cured at about 151°C for about 30 minutes. Table 2 shows the apparent and physical properties of the cured samples a-e.

[0022]Table 1 Example 1 Each raw material component of tread rubber

[0023]

[0024]

[0025]Table 2 Example 1 Performance Table of Tread Rubber

[0026] 151℃*30min ...

example 2

[0028]The tread rubber with the composition specified in Table 3 was prepared in a BR Banbury mixer. The preparation process adopted two separate feeding and mixing stages, namely, a non-productive mixing stage and a productive mixing stage. In the non-productive stage, mixing is carried out for about 2-3 minutes, until the rubber temperature reaches 160°C, which is complete. The mixing time in the productive stage is the time for the rubber temperature to reach 115°C. Among them, the carbon nanotube / butadiene pre-dispersed masterbatch is prepared by mechanical blending and in-situ modification, and then added to an internal mixer for mixing in a non-productive stage.

[0029]The tread rubber is referred to as sample A, sample B, sample C, sample D, and sample E here. Sample A is used here as a comparison sample, that is, the optimized rubber ratio is not used in the tread rubber.

[0030]All samples were cured at about 151°C for about 30 minutes. Table 4 shows the physical properties of ...

example 3

[0036]The tread rubber with the composition specified in Table 5 was prepared in a BR Banbury mixer. The preparation process adopted two separate feeding and mixing stages, namely, a non-productive mixing stage and a productive mixing stage. In the non-productive stage, mixing is carried out for about 2-3 minutes, until the rubber temperature reaches 160°C, which is complete. The mixing time in the productive stage is the time for the rubber temperature to reach 115°C. Among them, the carbon nanotube / butadiene rubber pre-dispersed masterbatch is prepared by in-situ modification by mechanical blending, and then added to an internal mixer for mixing in a non-productive stage.

[0037]The tread rubber is referred to as sample 1, sample 2, sample 3, and sample 4 here. Sample 1 is used here as a comparison sample, that is, the optimized rubber ratio is not used in the tread rubber.

[0038]All samples were cured at about 151°C for about 30 minutes. Table 6 shows the physical properties of cure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com