Method for preparing aramid fiber III nanometer coating fiber reinforced composite material

A technology of fiber reinforcement and composite materials, applied in fiber processing, conjugated synthetic polymer artificial filament, filament/wire forming, etc., can solve problems such as poor interface adhesion, and achieve good dimensional stability and good weather resistance And sunlight resistance, the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for preparing Aramid III nano-coated fiber reinforced composite material is specifically implemented as follows:

[0049] Step 1. Pre-treat the aramid III fiber to remove the spinning oil and other components remaining on the surface during processing. Soak it in absolute ethanol for 20 hours, then place it in an ultrasonic cleaner for 25 minutes, then clean it with deionized water and place it in an oven at 85°C for 5 hours to obtain clean aramid III fibers, and put them in plastic bags for later use;

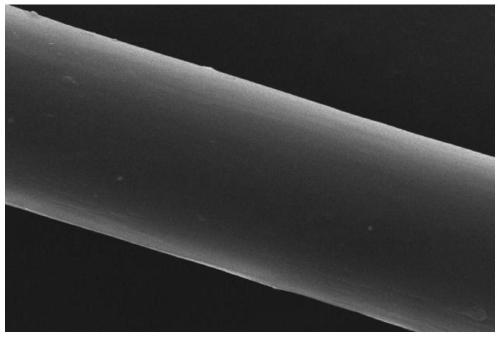

[0050] Step 2. Place the pretreated aramid III fiber in a plasma surface treatment device for plasma surface treatment, the treatment time is 5min, the discharge power is 52.5W, and the discharge pressure is 1000Pa, such as figure 2 Shown is the electron micrograph of Aramid Ⅲ fiber after treatment under this condition;

[0051] Step 3. Prepare a mixed solution of PAN and N-N dimethylformamide (DMF) to obtain a spinning solution, wherein the mass fraction of PAN is 6...

Embodiment 2

[0056] A method for preparing Aramid III nano-coated fiber reinforced composite material is specifically implemented as follows:

[0057] Step 1. Pre-treat the aramid III fiber to remove the spinning oil and other components remaining on the surface during processing. Soaked in absolute ethanol for 22 hours, then placed in an ultrasonic cleaner for 27 minutes, then cleaned with deionized water, placed in an oven at 85°C and dried for 5 hours to obtain clean Aramid III fibers, and put them in plastic bags for later use;

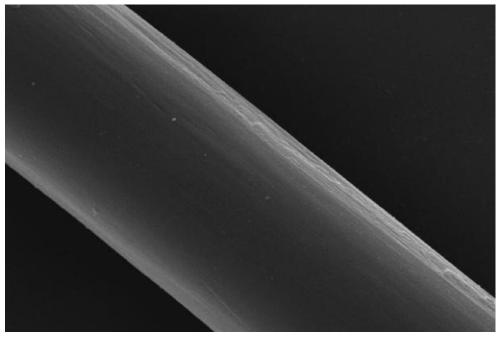

[0058] Step 2. Place the pretreated aramid III fiber in a plasma surface treatment device for plasma surface treatment. The treatment time is 7min, the discharge power is 62.5W, and the discharge pressure is 1300Pa. image 3 Shown is the electron micrograph of Aramid Ⅲ fiber after treatment under this condition;

[0059] Step 3. Prepare a mixed solution of PAN and N-N dimethylformamide (DMF) to obtain a spinning solution, wherein the mass fraction of PAN is 9% and th...

Embodiment 3

[0064] A method for preparing Aramid III nano-coated fiber reinforced composite material is specifically implemented as follows:

[0065] Step 1. Pre-treat the aramid III fiber to remove the spinning oil and other components remaining on the surface during processing. Soaked in absolute ethanol for 25h, and then placed in an ultrasonic cleaner for 27min, then rinsed with deionized water and placed in a 90℃ oven for 4h to dry to obtain clean Aramid III fiber, which is put into a plastic bag for later use;

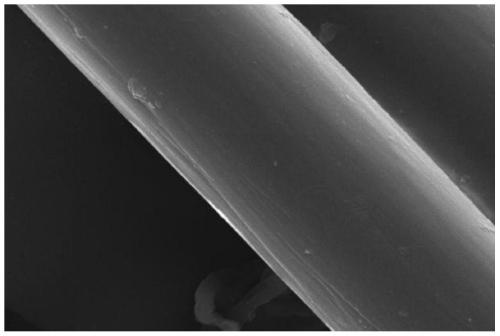

[0066] Step 2. Place the pretreated aramid III fiber in a plasma surface treatment device for plasma surface treatment. The treatment time is 9min, the discharge power is 72.5W, and the discharge pressure is 1600Pa, such as Figure 4 Shown is the electron micrograph of Aramid Ⅲ fiber after treatment under this condition;

[0067] Step 3. Prepare a mixed solution of PAN and N-N dimethylformamide (DMF) to obtain a spinning solution, wherein the mass fraction of PAN is 12% and the mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com