High-performance hydrogenated nitrile rubber material and preparation method thereof

A technology of hydrogenated nitrile rubber and nitrile rubber, which is applied in the field of rubber, can solve the problem of high cost, achieve the effects of low cost, excellent performance, and reduced use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

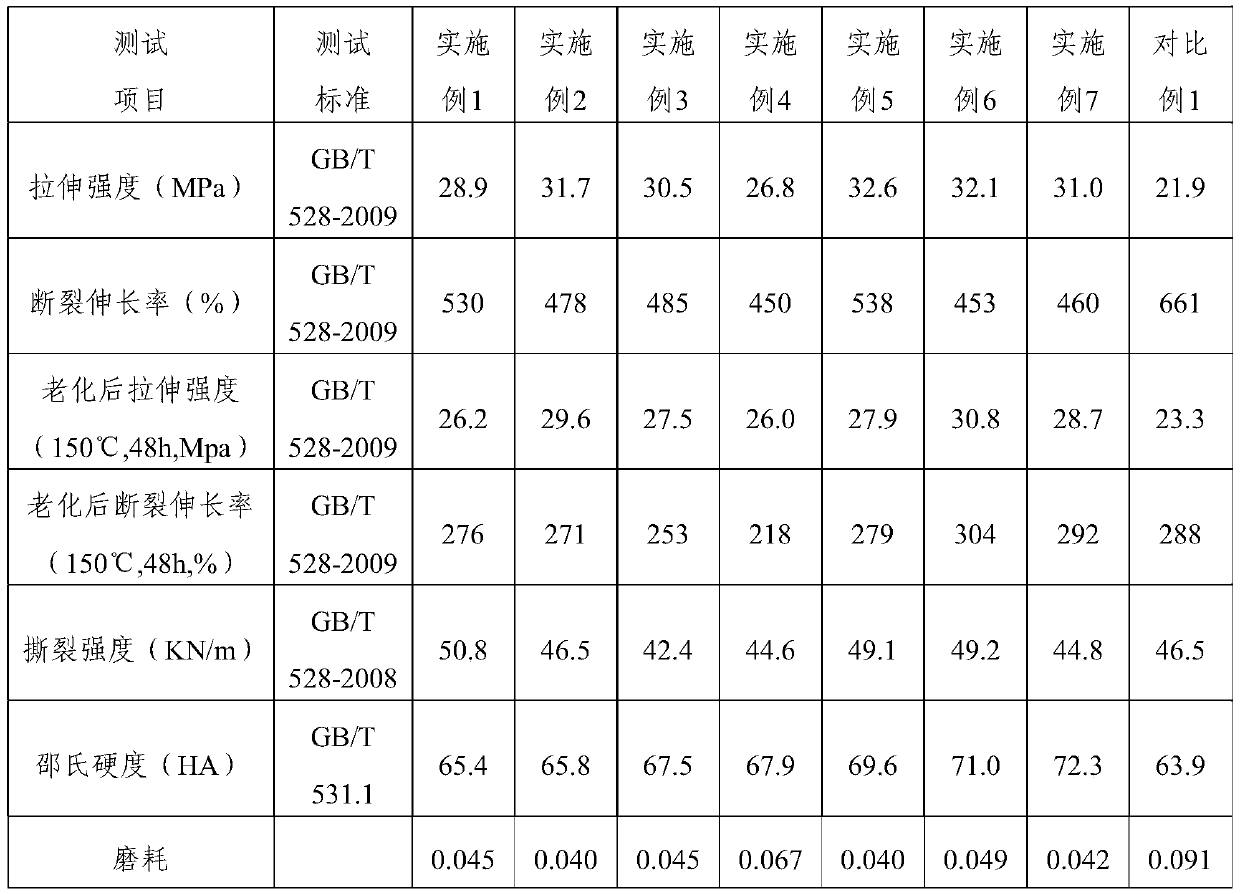

Examples

Embodiment 1

[0041] This embodiment provides a high-performance hydrogenated nitrile rubber material, including the following raw materials in parts by weight: 90 parts of hydrogenated nitrile rubber, 10 parts of hydrogenated nitrile rubber emulsion, 1 part of antioxidant 4010A, 5 parts of zinc oxide, and stearic acid 1 part, 40 parts carbon black N220, 5 parts DCP.

[0042] Wherein, the preparation method of the hydrogenated nitrile rubber emulsion is as follows: weigh a certain quality of nitrile rubber emulsion, according to the molar ratio of carbon-carbon double bonds in the nitrile rubber emulsion to hydrazine hydrate, hydrogen peroxide, and boric acid of 1.6: 1.75: 0.14 Weigh the corresponding masses of hydrazine hydrate, hydrogen peroxide and boric acid. Add the hydrazine hydrate directly to the emulsion. The boric acid is dissolved in a certain mass of deionized water and mixed with hydrogen peroxide evenly. Under certain stirring speed and temperature conditions, Use a peristaltic p...

Embodiment 2

[0049] This embodiment provides a high-performance hydrogenated nitrile rubber material, which includes the following raw materials by weight: 80 parts of hydrogenated nitrile rubber, 20 parts of hydrogenated nitrile rubber emulsion, 1 part of antioxidant 4010A, 5 parts of zinc oxide, and stearic acid 1 part, 40 parts carbon black N220, 5 parts DCP.

[0050] Wherein, the preparation method of the hydrogenated nitrile rubber emulsion and the preparation method of the high-performance hydrogenated nitrile rubber material are the same as in Example 1.

Embodiment 3

[0052] This embodiment provides a high-performance hydrogenated nitrile rubber material, including the following raw materials in parts by weight: 70 parts of hydrogenated nitrile rubber, 30 parts of hydrogenated nitrile rubber emulsion, 1 part of antioxidant 4010A, 5 parts of zinc oxide, and 1 part of stearic acid Parts, 40 parts of carbon black N220, 5 parts of DCP.

[0053] Wherein, the preparation method of the hydrogenated nitrile rubber emulsion and the preparation method of the high-performance hydrogenated nitrile rubber material are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com