Device and method capable of carbonizing plurality of tantalum sheets simultaneously

A tantalum sheet and carbonization temperature technology, which is applied in the field of semiconductor material preparation, can solve problems such as unfavorable product tracking, inability to distinguish the carbonization of tantalum sheets, etc., and achieves the effects of low processing difficulty, simple structure and high carbonization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

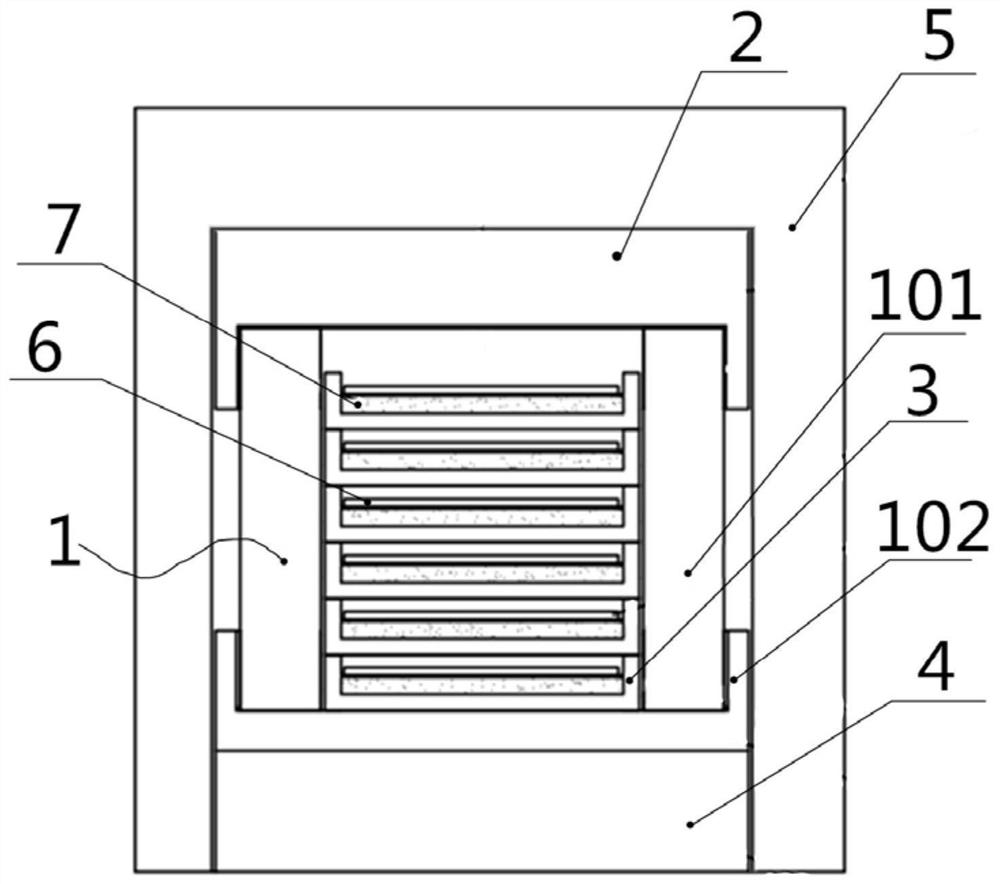

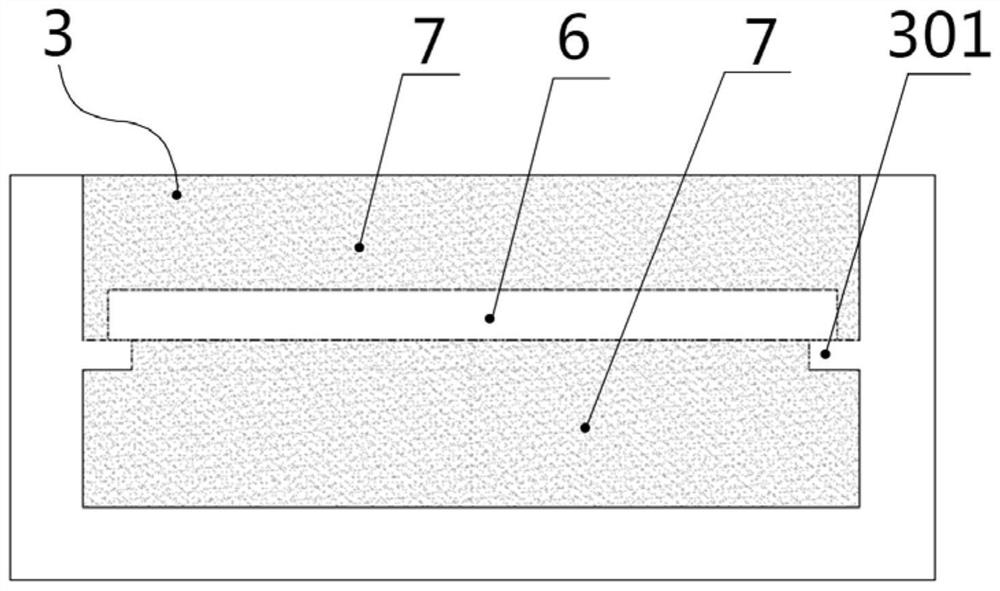

[0030] Specific implementation mode one: reference figure 1 , figure 2 Describe this embodiment, this embodiment proposes the following technical solutions:

[0031] A device capable of simultaneously carbonizing multiple tantalum sheets, comprising: a crucible body 1, a crucible upper cover 2, a tantalum sheet bracket 3, an insulation layer pad 4 and an insulation layer shell 5, the crucible body 1 is concave, and It is composed of a crucible shell 101 and a crucible bottom 102. A plurality of tantalum sheet brackets 3 are stacked in the crucible body 1. The tantalum sheet brackets 3 are concave and numbered on the outer wall, and the inner wall of the tantalum sheet bracket 3 is processed. There is a boss 301 for placing the tantalum sheet 6, the tantalum sheet bracket 3 is made of graphite material, the crucible upper cover 2 is covered on the crucible body 1, so that the crucible body 1 and the crucible upper cover 2 form a closed structure, and the heat preservation Th...

specific Embodiment approach 2

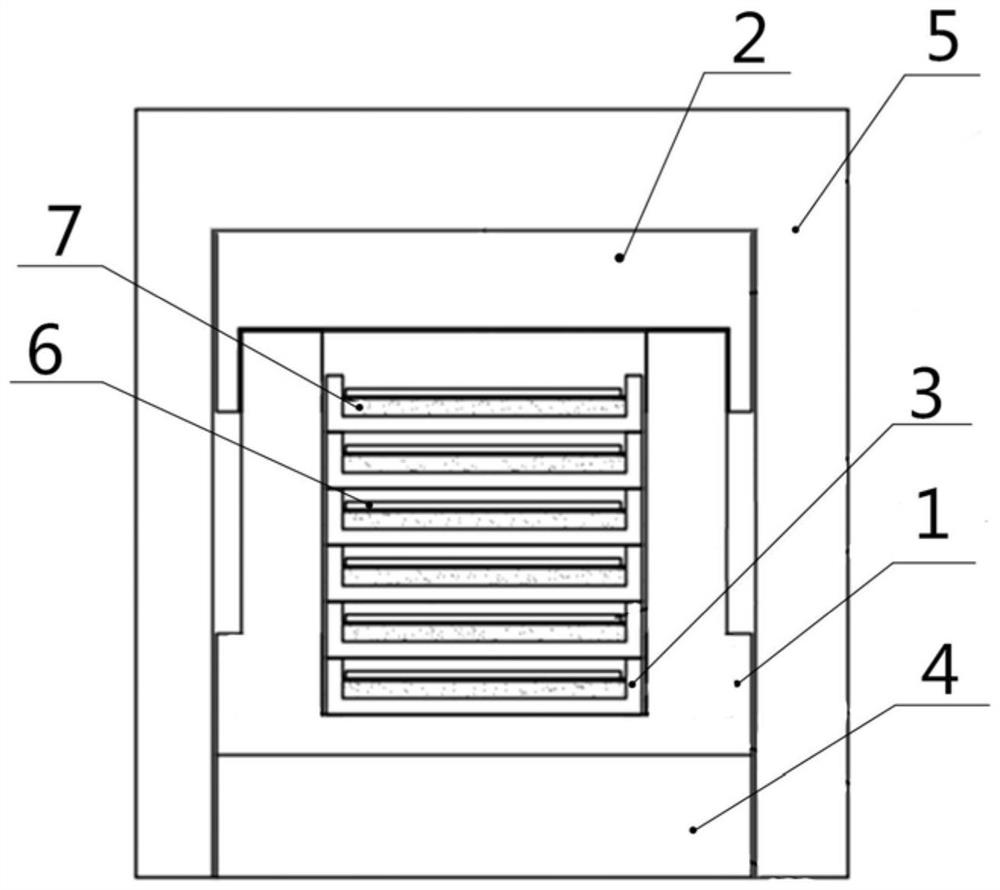

[0039] Specific implementation mode two: reference image 3 , figure 2 Describe this embodiment, this embodiment proposes the following technical solutions:

[0040] A device capable of carbonizing multiple tantalum sheets at the same time, comprising: a crucible body 1, a crucible upper cover 2, a tantalum sheet bracket 3, an insulation layer pad 4 and an insulation layer shell 5, the crucible body 1 is concave, multiple A tantalum sheet bracket 3 is stacked in the crucible body 1. The tantalum sheet bracket 3 is concave and engraved with a number on the outer wall. The inner wall of the tantalum sheet bracket 3 is processed with a boss 301 for placing the tantalum sheet 6, The sheet bracket 3 is made of graphite material, and the crucible upper cover 2 is covered on the crucible body 1, so that the crucible body 1 and the crucible upper cover 2 form an airtight structure, and the insulating layer pad 4 has the same bottom area as the crucible body 1, The crucible body 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com