Wire harness rapid detection system

A detection system and wire harness technology, applied in the field of wire harness processing, can solve the problems of unsuitable batch processing, high labor cost, and difficult operation, and achieve the effect of simple structure, good versatility, and efficient detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

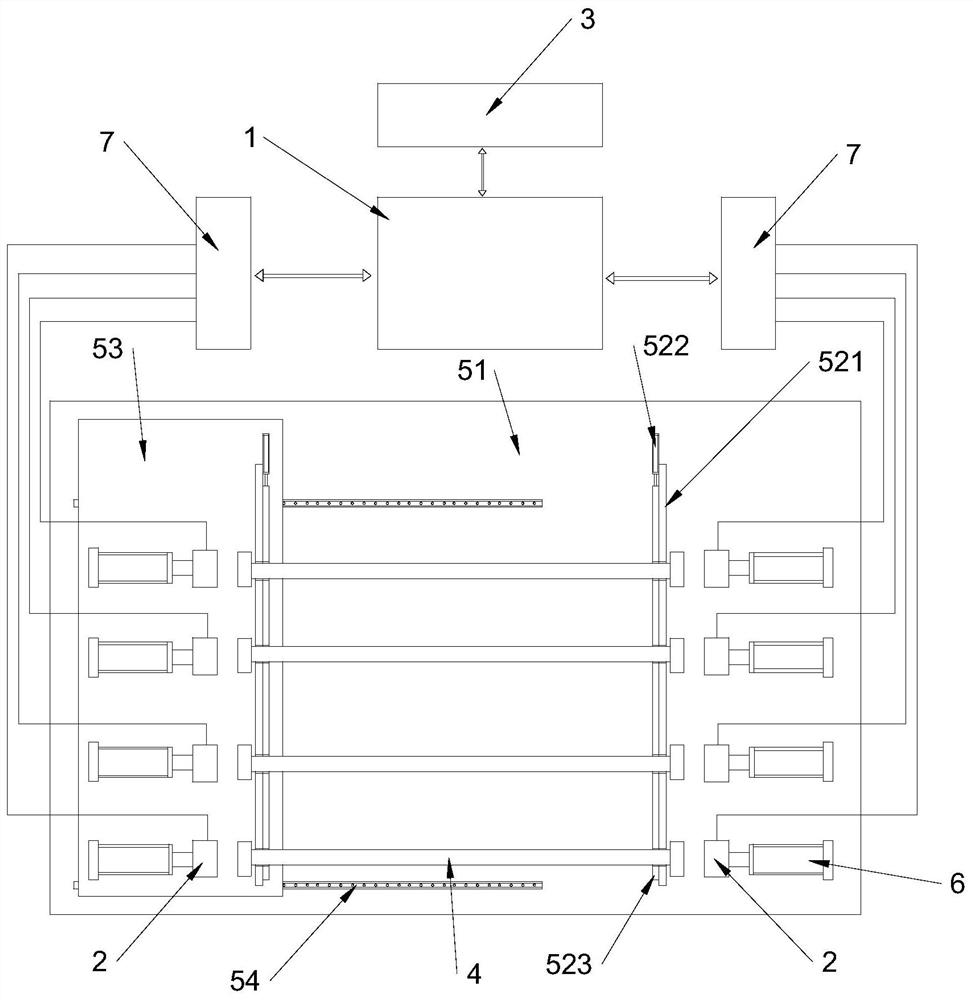

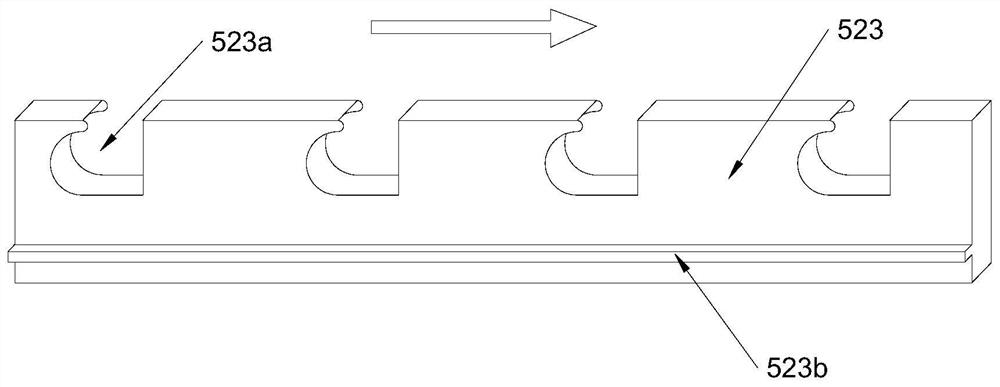

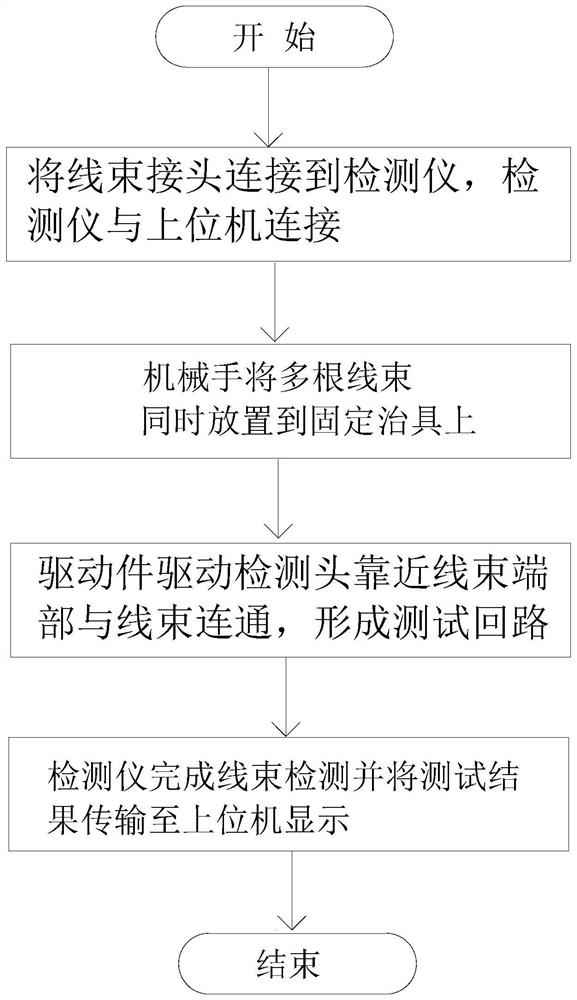

[0021] See attached Figure 1-2 As shown, a wire harness rapid detection system of the present invention includes a tester 1, a test head 2, a fixing jig and a host computer 3, the fixing jig is used for fixing the wire harness 4, and the fixing jig includes a bottom plate 51 and a wire harness clamp arranged on the bottom plate 51 , the wire harness clamp can fix a plurality of wire harnesses 4 arranged side by side. Moreover, the width of the wire harness 4 fixture is adjustable, and can be used to clamp wire harnesses 4 of different lengths. The test head 2 is located on both sides of the fixing fixture, and the test head 2 can approach / far away from the two ends of the wire harness 4 under the action of the driving member 6 and conduct with the wire harness 4 to form a test loop. The driver 6 is fixed on the bottom plate 51 and is a cylinder. The test head 2 is detachably connected to the driver 6 , and different test heads 2 can be replaced according to different wire ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com