High-temperature steam corrosion resistant coating for zirconium alloy cladding tube

A technology for corroding coatings and cladding tubes, which is applied in the field of surface modification of reactor nuclear fuel zirconium alloy claddings, can solve the problems of plasticity reduction, failure, and high solid solubility of oxygen in cladding tubes, so as to improve wear resistance and durability. The effect of corrosion hydrogen absorption performance and strong high temperature steam corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

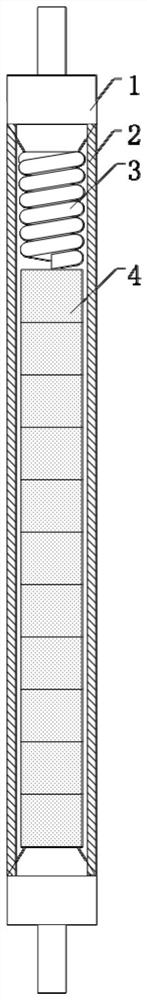

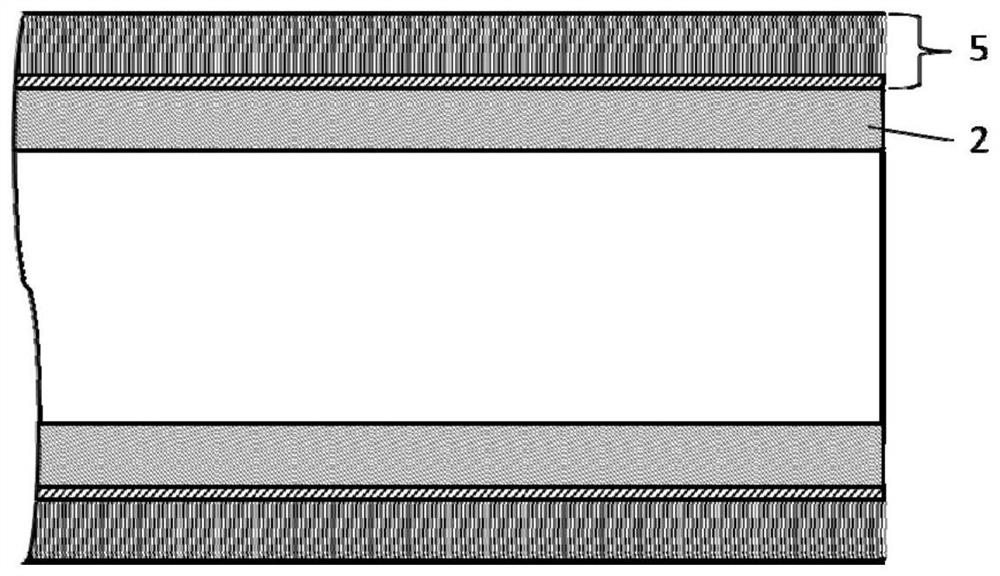

[0033] A coating with pure Cr as the transition layer and pure Zr as the working layer is coated on the surface of the zirconium alloy sample. Its microstructure is as Figure 5 shown.

[0034] The characteristics of the embodiment of the present invention are: 1. Cr is used as the transition layer, which prevents oxygen from diffusing to the zirconium alloy substrate under high temperature conditions; 2. Pure Zr is used as the working layer, with a thickness of about 1-2 μm and high-temperature oxidation to ZrO 2 3. The Cr transition layer is only 2 μm, and the neutron economic loss of the fuel rod is equivalent to 1 / 2 of Comparative Example 2. After corroding in water vapor at 1000°C for 60 minutes, the weight gain is 500mg / dm 2 , the corrosion weight gain curve is as Figure 4 As shown, the corrosion weight gain was reduced by more than 85% compared to the uncoated zirconium alloy (Comparative Example 1).

Embodiment 2

[0036] A coating with pure Cr as the transition layer and zirconium + zirconia as the working layer is coated on the surface of the zirconium alloy sample.

[0037] The characteristics of the embodiment of the present invention are: 1. Using 1 μm of Cr as the transition layer prevents the oxygen element from diffusing to the zirconium alloy matrix under high temperature conditions, and the neutron economic loss of the fuel rod is only 1 / 4 of that of Comparative Example 2; 2. 1. Use 10μm pure Zr as the working layer, after high-temperature pre-oxidation treatment to generate zirconia with a thickness of about 6μm, after corroding in water vapor at 1000°C for 60min, the weight gain is less than 500mg / dm 2 , The corrosion weight gain was reduced by more than 85% compared with Comparative Example 1.

Embodiment 3

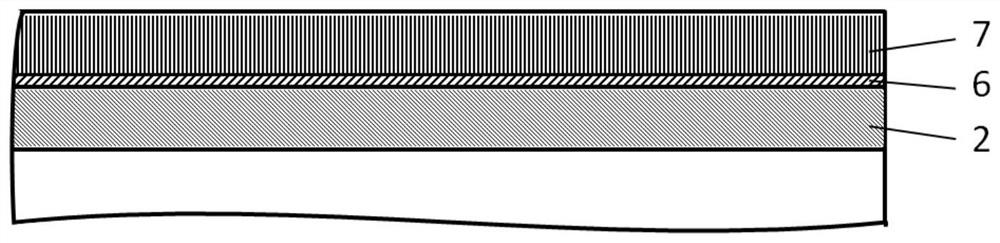

[0039] The surface of the zirconium alloy sample is coated with CrN as the transition layer and zirconium as the working layer.

[0040] The characteristics in the embodiment of the present invention are: 1. The CrN of 2 μm is used as the transition layer, which prevents the oxygen element from diffusing to the zirconium alloy matrix under high temperature conditions, and the neutron economic loss of the fuel rod is significantly lower than that of Comparative Example 2; 2. Compared with Compared with Example 1, the surface hardness is significantly improved; 3. Using 2 μm pure Zr as the working layer, after corroding in water vapor at 1000°C for 60 minutes, the weight gain is about 500mg / dm 2 , The corrosion weight gain was reduced by more than 85% compared with Comparative Example 1.

[0041] Therefore, the coating of the invention significantly improves the corrosion resistance of the zirconium alloy cladding tube, and significantly reduces the neutron economic loss of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com