A kind of multi-stage atomizing agent feeding process

An atomizer and process technology, which is applied to tobacco, tobacco processing, tobacco preparation, etc., can solve the problems of stiffness of thin slices, poor curling performance, affecting the smoking quality of cigarette factories, and achieve rapid absorption and improve sensory quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

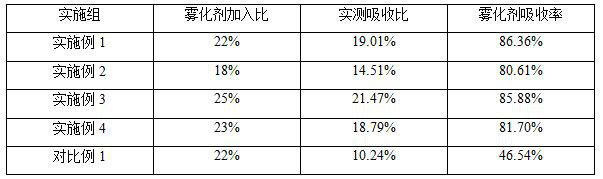

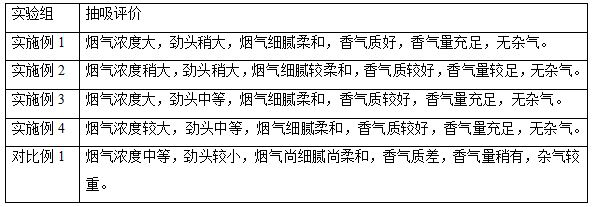

Examples

Embodiment 1

[0024] A multi-stage atomizing agent feeding process, comprising the following steps:

[0025] a. Leaf silk pretreatment: the incoming leaf silk enters the microwave heating process, the microwave magnetron is turned on at a ratio of 60%, and the leaf silk is warmed. Silk insulation. Dissolving the rosin into an ethanol solution with a concentration of 75% to obtain a rosin solution with a concentration of 15%, spraying the rosin solution to the insulated leaf silk, so that the mixing mass ratio of rosin and the leaf silk is 3:100, and then the leaf silk is heated to 125°C and heated for 4h.

[0026] b. Feeding: According to parts by mass, mix 9 parts of glycerol and 1 part of ethanol with a concentration of 70% to obtain an atomizing agent, and heat the atomizing agent to 95°C by steam to reduce its viscosity for use.

[0027] After microwave heating, the leaf silk enters the multi-stage micro-unit feeding process. The multi-stage micro-unit feeding machine includes a trans...

Embodiment 2

[0033] A multi-stage atomizing agent feeding process, comprising the following steps:

[0034] a. Leaf silk pretreatment: Dissolve the rosin into an ethanol solution with a concentration of 75% to obtain a rosin solution with a concentration of 10%, and spray the rosin solution to the leaf silk at room temperature, so that the mixing mass ratio of rosin and leaf silk is 1:100, The leaf silk was then heated to 120°C and heated for 3h.

[0035] b. Feeding: According to mass parts, mix 8 parts of glycerol and 1 part of ethanol with a concentration of 70% to obtain an atomizing agent, and heat the atomizing agent to 90 ℃ by steam to reduce its viscosity and prepare it for later use. At 65°C, the heated atomizing agent was directly sprayed to the leaf silk, and the mixing mass ratio of the atomizing agent and the leaf silk was 18:100.

[0036] c. Drying: Use hot air at 120°C to dry to a moisture content of 12%.

[0037] d. For silk storage, the dried finished leaf silk is stored...

Embodiment 3

[0040] A multi-stage atomizing agent feeding process, comprising the following steps:

[0041] a. Leaf silk pretreatment: Dissolve rosin into 75% ethanol solution to obtain a 20% rosin solution. After heating the leaf silk to 130°C, spray the rosin solution onto the leaf silk, so that the rosin and the leaf silk are mixed with each other. The mixing mass ratio is 5:100, and the temperature is kept for 5h.

[0042] b. Feeding: According to mass parts, mix 10 parts of glycerol and 1 part of ethanol with a concentration of 70% to obtain an atomizing agent, and heat the atomizing agent to 100 ℃ by steam to reduce its viscosity for use.

[0043]One-time feeding: using the multi-stage micro-unit feeding in Example 1, that is, the thickness of the leaf silk is 10 mm, the air pressure is used to induce the spraying agent, the air pressure of the injection is 0.28 mpa, the temperature of the feeding cavity is controlled to 90 ° C, and the atomization is carried out. The mixing mass ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com