Method for preparing Ag3PO4/GO/HAP composite photocatalyst by utilizing bovine bones

A composite photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of limiting the application and development of silver phosphate photocatalysts, poor stability of silver phosphate, and reduced photocatalytic ability , to achieve excellent photocatalytic activity, low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

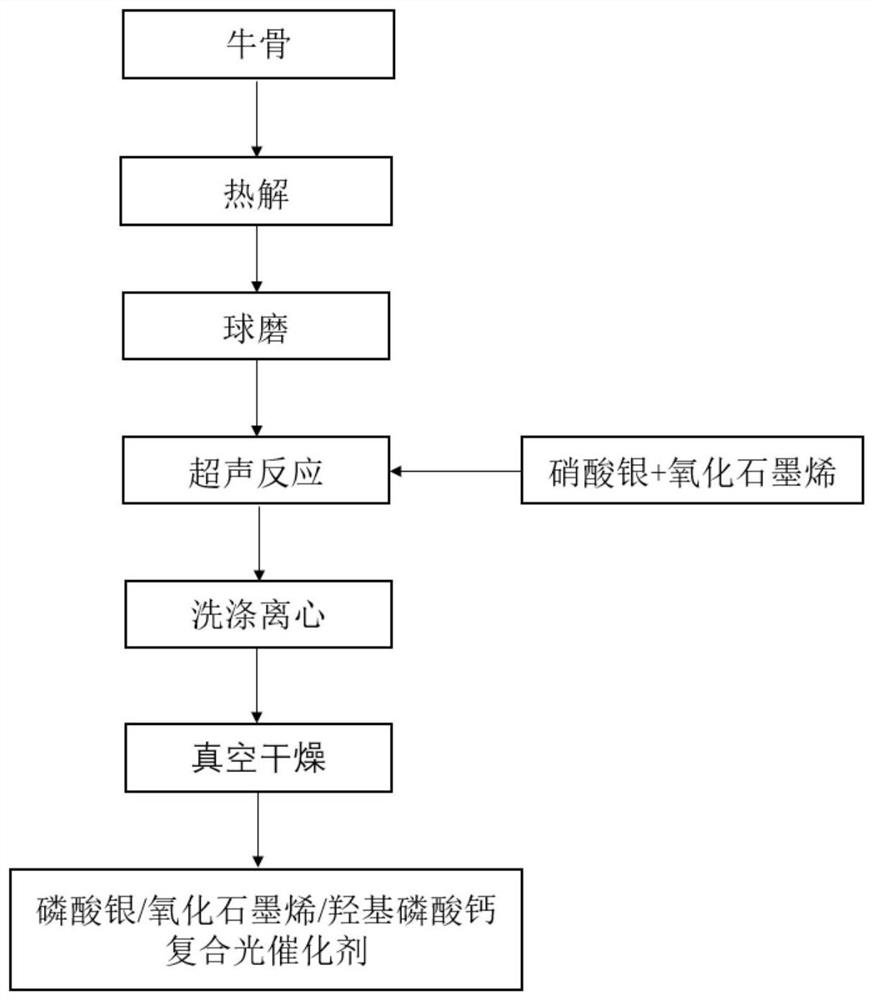

[0017] The bovine bone is broken into small pieces, boiled with deionized water for several hours and washed several times until the oil and collagen are removed, and then pyrolyzed at 800°C for 8 hours to obtain biomass calcium hydroxyphosphate, and finally use a high-energy ball mill 10:1 ball milling for 20h to make it into micro-nano particles.

[0018] The above-mentioned hydroxy calcium phosphate powder was added to the silver nitrate solution dispersed with graphene oxide for 30 minutes in the dark and ultrasonic reaction, wherein m(HAP):m(Ag 3 PO 4 )=1:2, m(GO):m(Ag 3 PO 4 + HAP) = 2:100.

[0019] The product obtained in the previous step was washed with deionized water and absolute ethanol in the dark and centrifuged several times to obtain Ag 3 PO 4 / GO / HAP complex.

[0020] Put the above product into a vacuum drying oven and dry it in vacuum at 60°C for 8 hours to obtain Ag 3 PO 4 / GO / HAP composite photocatalyst, keep away from light for future use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com