Combined Electrochemical Deposition-Electrolytic Machining Method Based on Mask Electric Field Confinement

A combined processing and electrochemical technology, applied in the field of combined electrochemical deposition and electrolytic processing based on mask electric field constraints, can solve problems such as poor surface quality, and achieve the effect of protecting equipment, improving processing efficiency, and avoiding high-level corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

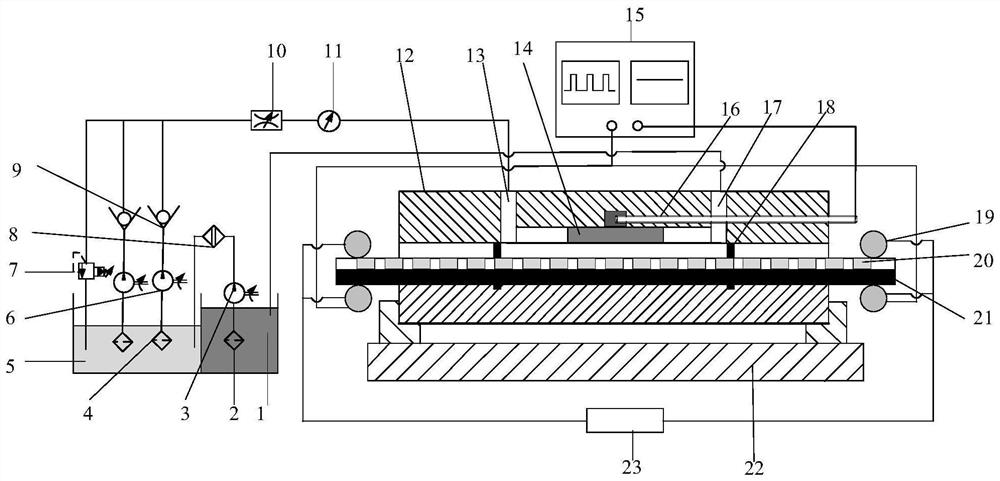

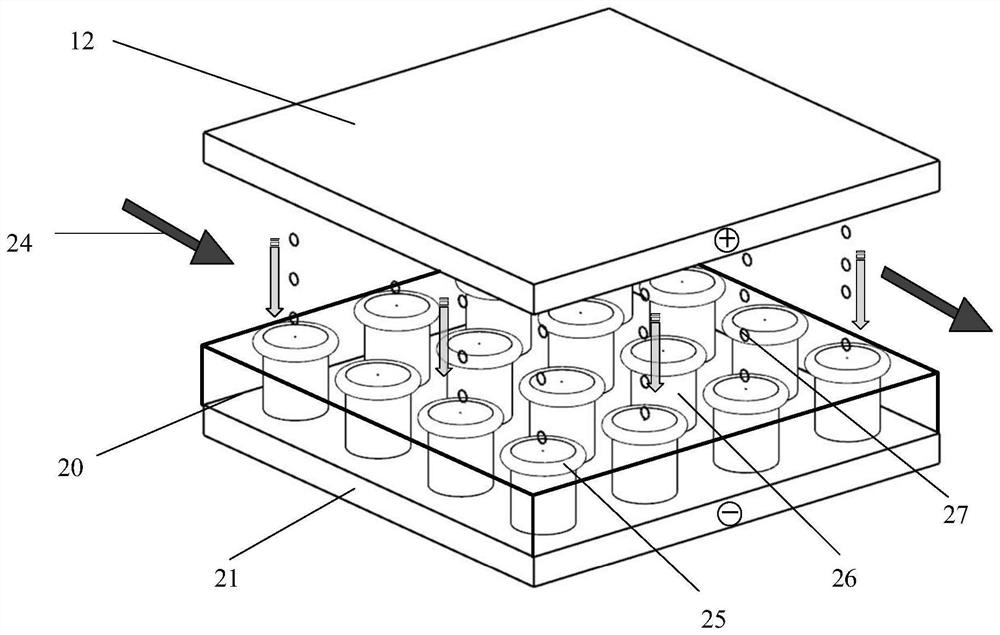

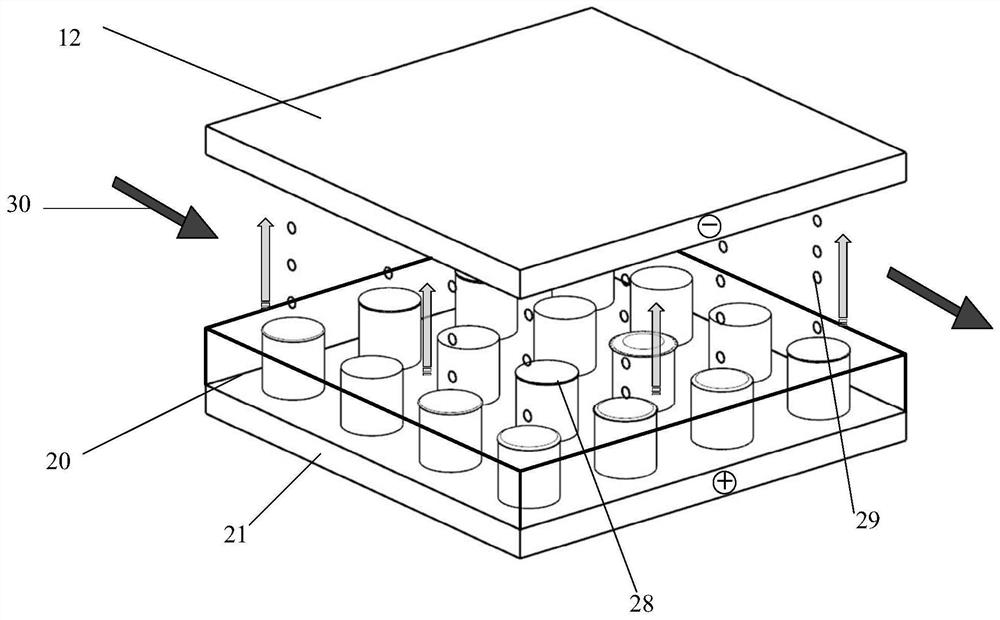

[0046] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0047] The embodiment of the present invention discloses a combined electrochemical deposition-electrolysis processing method based on mask electric field constraints. This method is applied to the surface of micro-sized parts of various miniaturized and miniaturized equipment in the fields of aerospace, national defense and military industry, and advanced medical equipment. Microstructure processing, the surface microstructure of such tiny parts has complex shape and structure, high forming precision, small surface roughness, no microcracks and internal stress, and special surface is required in acid-base, high temperature, high pressure and other occasions. Performance, traditional processing methods cannot meet this requirement,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com