A method and system for machining threads on the surface of hard and brittle materials

A technology of hard and brittle materials and surface processing, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of low processing precision and low processing efficiency, and achieve high processing precision, high processing efficiency and fast scanning speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

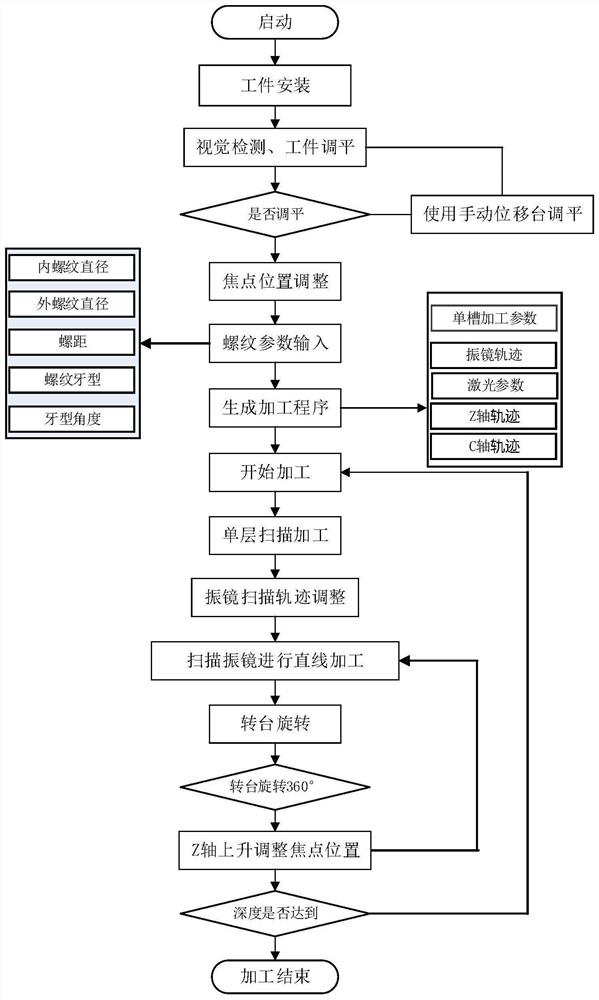

[0061] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

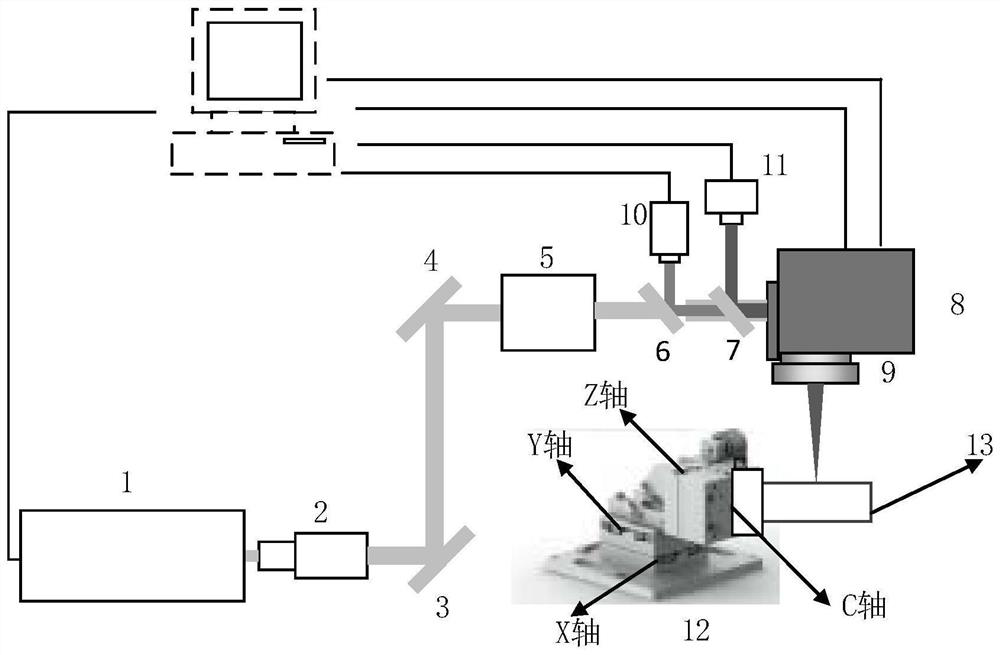

[0062] The invention uses a two-dimensional vibrating mirror laser scanning system combined with a four-axis motion platform to realize thread processing on the surface of hard and brittle materials. systems such as figure 1 As shown, it includes a laser processing system and a four-axis motion platform 12 . The laser processing system includes a femtosecond laser 1, a beam expander 2, a first reflector 3, a second reflector 4, a spatial light modulator 5, a dichroic mirror 6, A dichroic mirror 7 , a two-dimensional scanning galvanometer 8 and a field mirror 9 . The laser processing system also includes a distance measuring sensor 10 and a coaxial vision system 11 . Wherein the coaxial vision system 11 may be a coaxial camera. The ranging sensor 10 is used to detect the focus position and level the workpiece to be processed, and the coaxial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com