Composite material and construction method for absorbing gas spilled from face

A technology of composite materials and construction methods, applied in the fields of application, earthwork drilling, household appliances, etc., to achieve the effect of reducing safety hazards, reducing gas release, and reducing the risk of gas outburst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

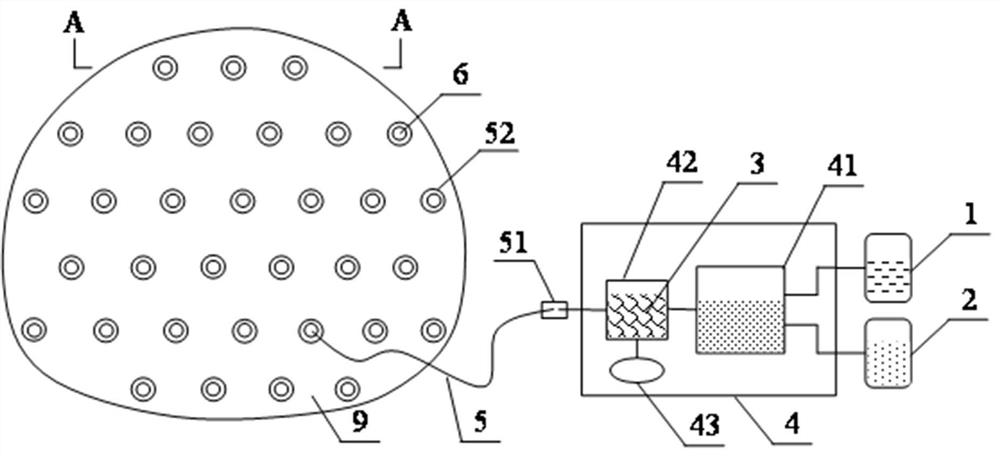

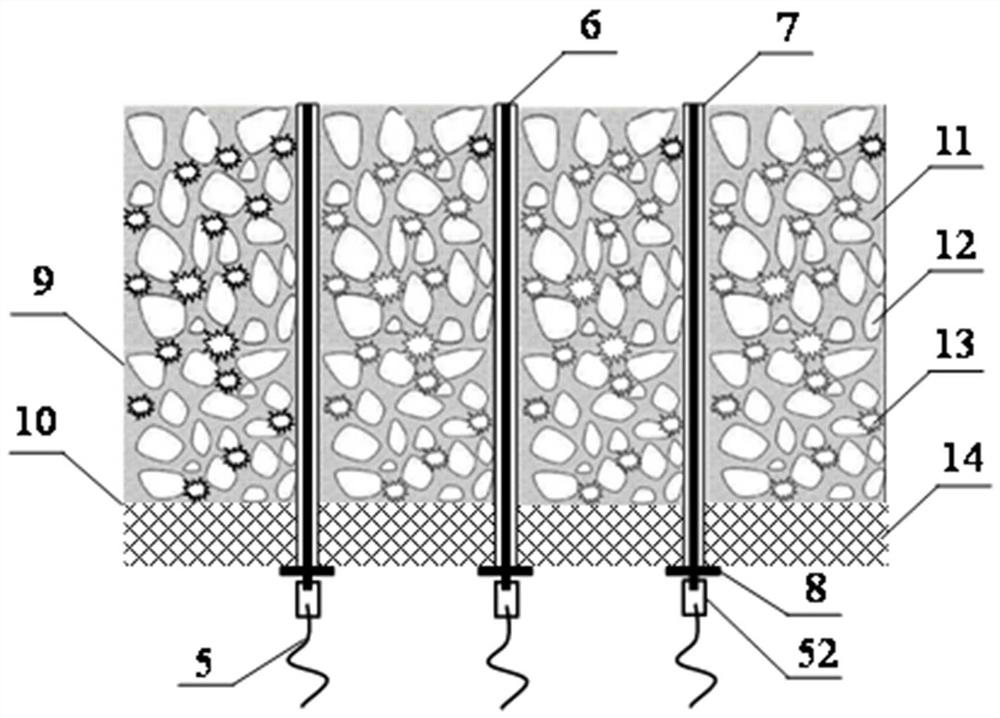

[0025]In order to make the object of the present invention, technical solutions and advantages more clearly understood, the following in conjunction with the accompanying drawings and specific embodiments, the technical solutions in the embodiments of the present invention are clearly and completely described, obviously, the described embodiments are only part of the embodiments of the present invention, not all embodiments. It should be understood that the specific embodiments described herein are merely used to explain the present invention and are not intended to qualify the present invention.

[0026] The present invention provides a composite material for adsorption of palm surface overflow gas, comprising activated carbon fibers, viscosites, blowing agents, the mass ratio of the activated carbon fibers to the viscosite is 1: 3 ~ 1: 6, the activated carbon fibers are mixed with the viscous agent to obtain a thickening solution, the bulk ratio of the thickening solution to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com