Quick-drying elastic paint and using method thereof

An elastic paint and elastic resin technology, applied in the field of elastic paint, can solve problems such as paint waste and equipment damage, and achieve the effects of long activation period, increased production capacity, and reduced baking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1

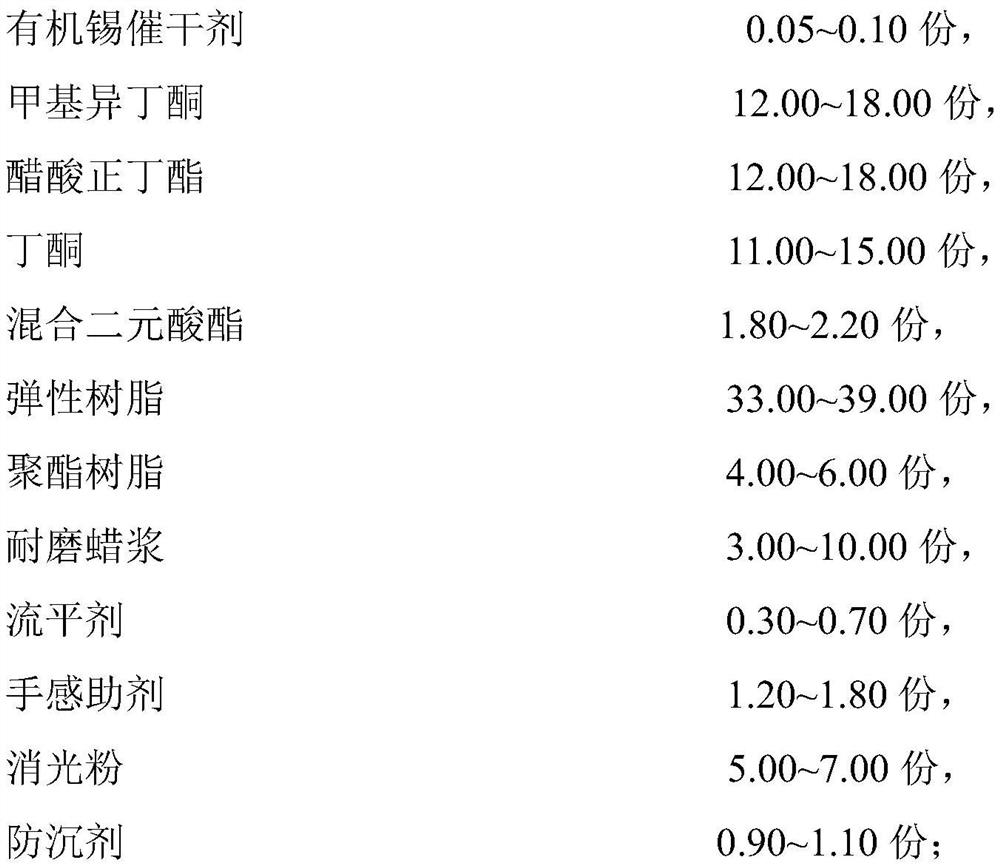

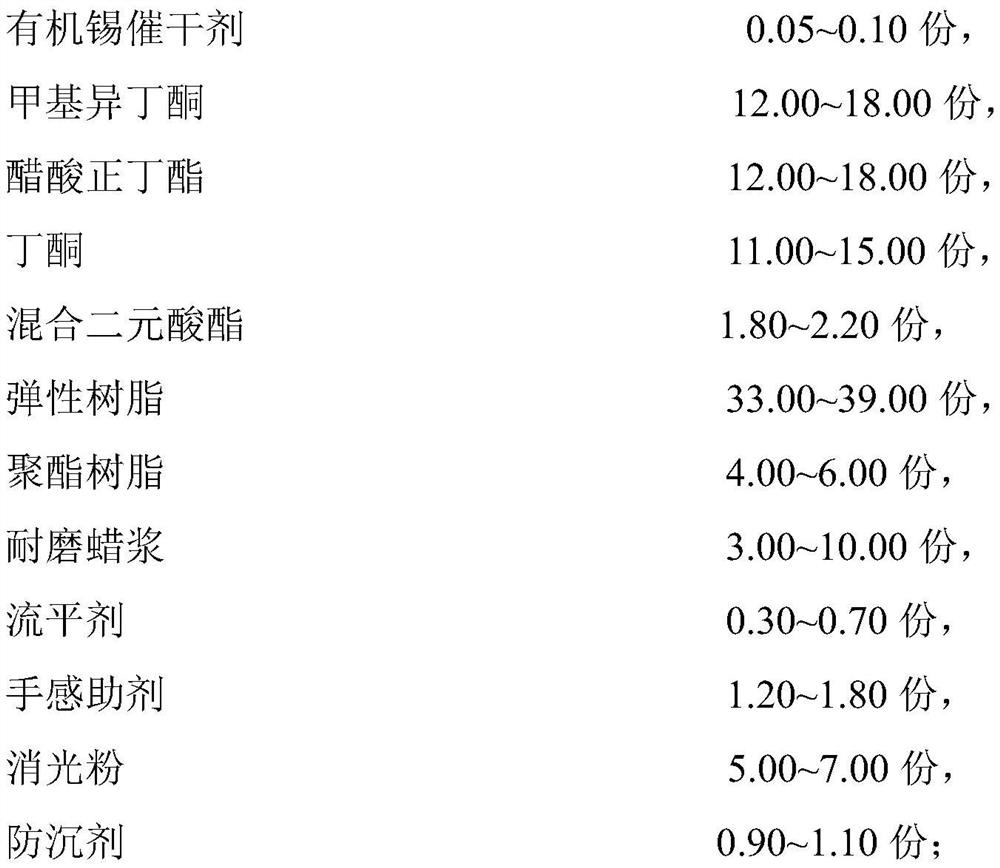

[0040] Prepare main agent A component according to the weight part of the following table:

[0041] component name Example 1 Comparative example 1 DBTDL 0.08 0.68 MIBK 14.00 14.00 BAC 14.00 14.00 MEK 12.00 11.40 DBE 2.00 2.00 GALSTAFF MX-353 36.00 36.00 A86 5.00 5.00 BYK258 8.00 8.00 BYK399 0.50 0.50 BYK378 1.50 1.50 K-500 6.00 6.00 6900-20X 1.00 1.00

[0042] Curing agent B component is Desmodur N3390.

[0043] Prepare diluent C component according to the following table weight parts:

[0044]

[0045]

[0046] Dilute component A, component B and component C according to the ratio of 5:1:2.5, the viscosity of Tu-2 cups after dilution is 8~12s, then carry out spraying construction, and finally bake at 55°C for 13 minutes .

Embodiment 1

[0047] The paint film test test result of embodiment 1 and comparative example 1 is shown in the table below:

[0048]

[0049] It can be seen from the above table that the quick-drying elastic paint of the present invention better retains the basic properties of the elastic paint, and can achieve a longer pot life and a shorter drying time.

Embodiment 2~3

[0051] Prepare main agent A component according to the weight part of the following table:

[0052] component name Example 2 Example 3 DABCOT12 0.05 0.10 MIBK 18.00 12.00 BAC 12.00 18.00 MEK 15.00 11.00 DBE 2.20 1.80 GALSTAFF MX-353 33.00 39.00 A86 6.00 4.00 BYK258 3.00 10.00 BYK399 0.70 0.30 BYK378 1.20 1.80 K-500 7.00 5.00 6900-20X 0.90 1.10

[0053] Curing agent B component is Desmodur N3390.

[0054] Prepare diluent C component according to the following table weight parts:

[0055] component name Example 2 Example 3 EAC 45.00 53.00 DAA 34.00 31.00 IPA 11.00 7.00 DBTDL 1.50 1.00 PDO 10.50 7.00

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com