Czochralski method single crystal furnace and melt temperature gradient control method thereof

A technology of melt temperature and control method, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve problems such as temperature rise, single crystal silicon quality decline, single crystal silicon oxygen content increase, etc., to achieve easy operation , The structure of the device is simple, the effect of improving the efficiency of crystal pulling and the quality of crystal pulling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

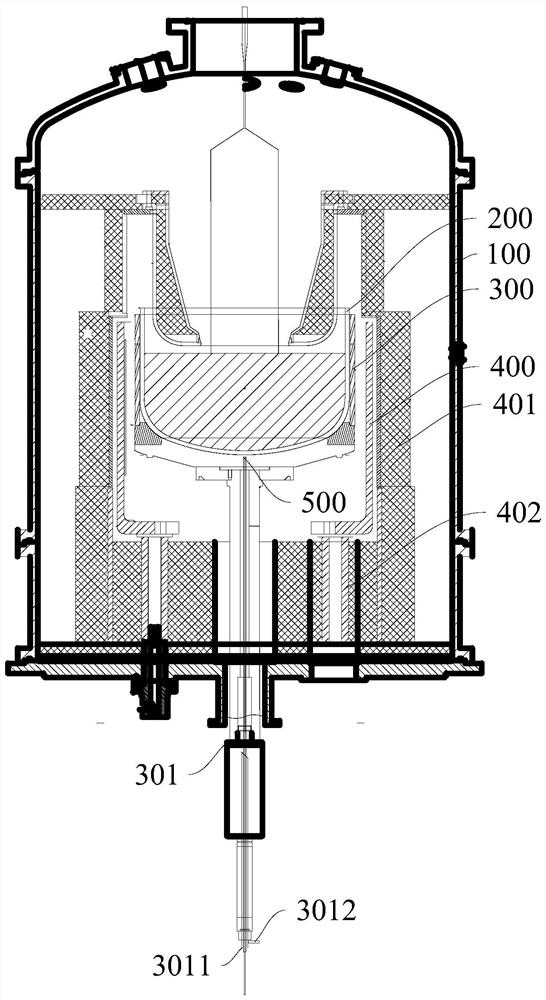

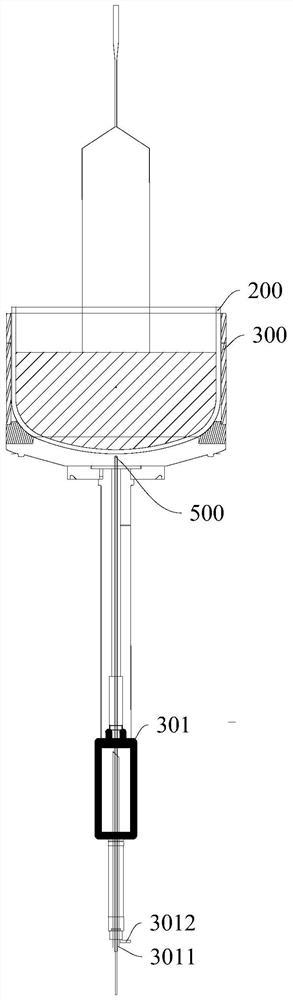

[0040] see figure 2 with image 3 , the Czochralski method single crystal furnace in this embodiment includes a furnace body 100, and disposed in the furnace body 100:

[0041] Crucible, comprising quartz crucible 200 and graphite crucible 300 wrapped outside quartz crucible 200, the bottom of graphite crucible 300 is provided with crucible shaft 301;

[0042] The heater 400 is arranged on the outside of the graphite crucible 300; the outside of the heater 400 is provided with an insulating layer 401, and the bottom of the heater 400 is provided with an electrode foot 402;

[0043] Temperature measuring device, the temperature measuring device of the present embodiment is thermocouple 500, is installed in the bottom of graphite crucible 300, and is arranged through crucible shaft 301, and the top temperature probe of thermocouple 500 is 5~10mm from the bottom of quartz crucible 200; The bottom of the thermocouple 500 has a signal data line connected to the data processor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com