Large-span concrete construction cantilever formwork structure

A concrete, large-span technology, applied in the fields of formwork/formwork/work frame, building structure, and on-site preparation of building components, etc., can solve the problems of mutual interference of devices, delivery to the corresponding operation level, and mutual staggering, etc. To achieve the effect of fast installation, simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

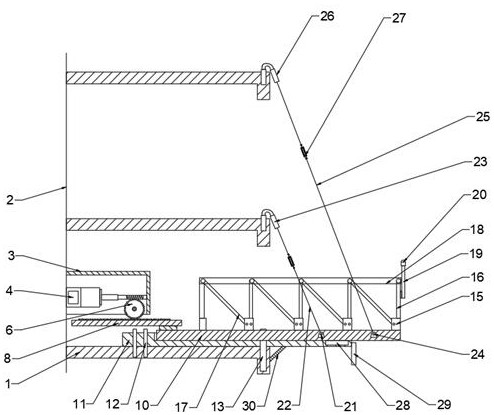

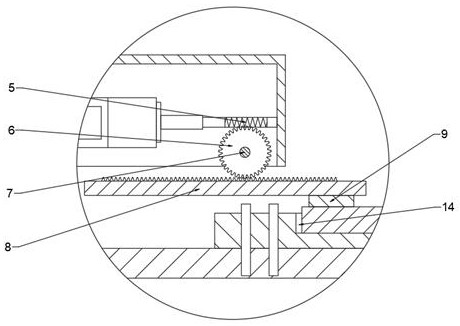

[0022] Example 1: Please refer to Figure 1-3 , a large-span concrete construction cantilever formwork structure, including a floor slab 1 and a wall 2, the wall 2 is fixedly connected with a cover plate 3, and the cover plate 3 is provided with a motor 4 inside, and the motor 4 and the wall 2 adopt Fixed connection, the output end of the motor 4 is fixedly connected with a worm 5, the other end of the worm 5 is rotationally connected with the cover plate 3, the worm 5 is meshed with a worm wheel 6, the middle part of the worm wheel 6 is fixedly connected with a rotating shaft 7, and the two ends of the rotating shaft 7 are connected to the cover The plate 3 is connected by rotation, the bottom of the worm wheel 6 is threadedly connected with a rack 8, the bottom of the right side of the rack 8 is fixedly connected with a fixed block 9, the bottom of the fixed block 9 is fixedly connected with a platform sliding plate 10, and the floor plate 1 is provided with The fixed plate ...

Embodiment 2

[0035] Embodiment 2: This embodiment is a further improvement of the previous embodiment: the No. 1 steel rope 22, the No. 1 steel rope 22 and the No. 1 drawbar 23 are provided with two groups on the front side and the rear side of the sliding plate 10, The No. 2 steel rope 25, the No. 2 steel rope 25 and the No. 2 drawbar 26 are provided with 2 groups altogether at the front side and the rear side of the sliding plate 10, and the No. The steel rope 25 is arranged on the three-story floor boards 1, and the bearing pressure of the sliding board 10 can be evenly distributed on different floor boards 1, so as to reduce stress concentration and improve safety.

[0036]The working principle of the present invention is: when the present invention is in use, the assembly and installation can be completed, the power is turned on to start the motor 4, the output shaft of the motor 4 rotates to drive the worm 5 to rotate, the worm 5 rotates to drive the worm wheel 6 to rotate, and the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com