Calcium aluminate fully-combined tin bath top cover brick for float glass tin bath and preparation method thereof

A float glass and calcium aluminate technology, applied in the field of refractory materials, can solve the problems of reducing the life of electric heating elements, increasing the expansion of reinforcement, and increasing maintenance costs, so as to improve profits, increase yield, and be easy to install and maintain. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

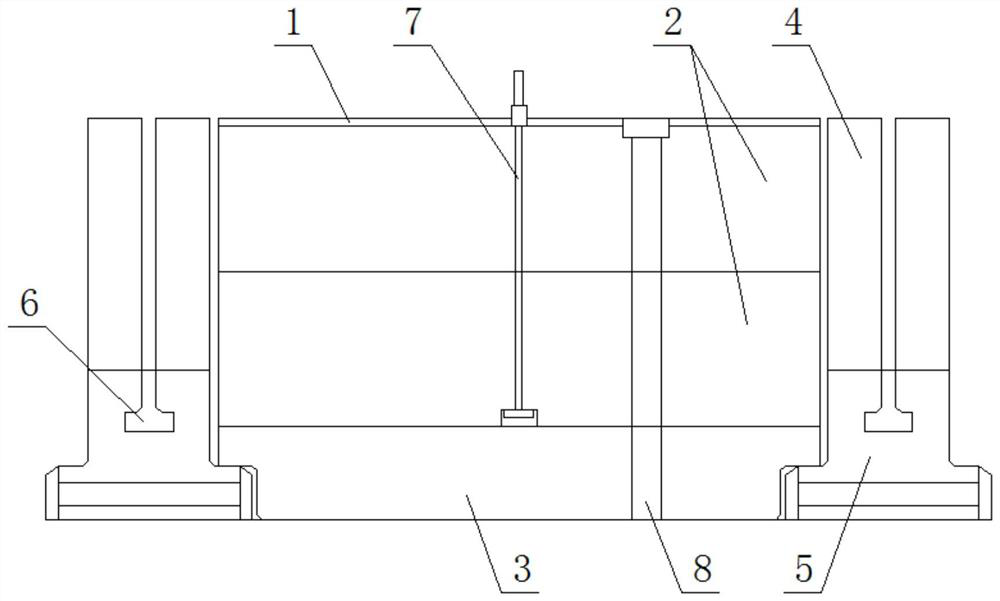

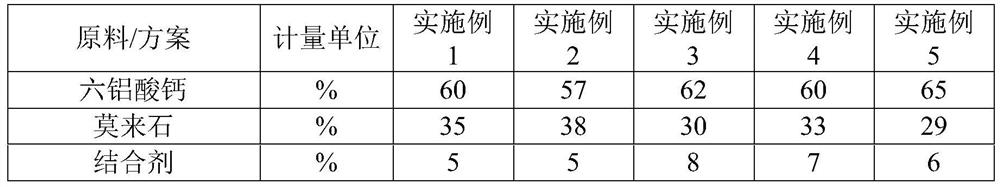

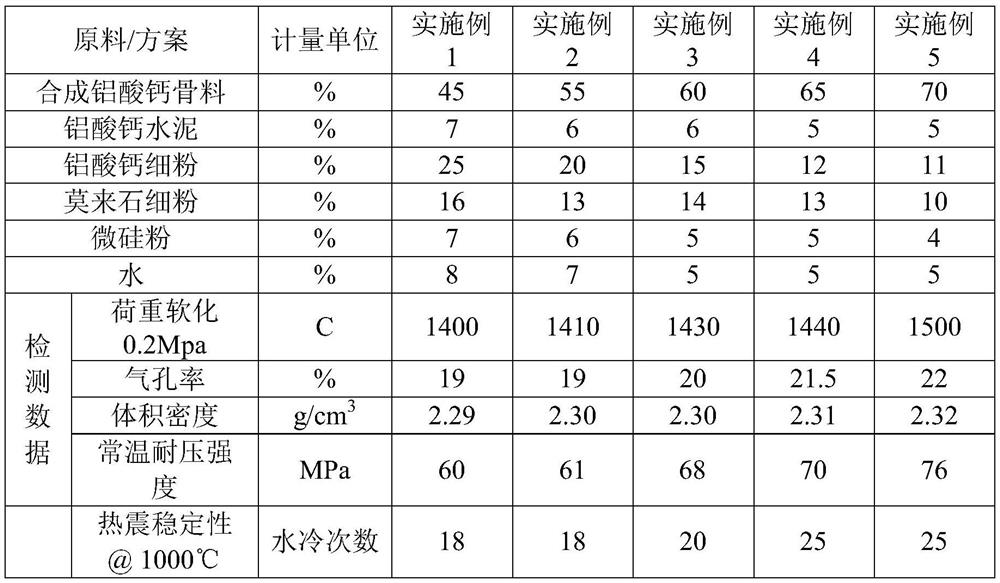

[0041] The calcium aluminate fully assembled tin bath roof brick for the float glass tin bath described in Example 1 is composed of a supporting brick and a combined brick, and the supporting brick is composed of a bottom calcium aluminate hot facing brick and an upper lightweight Mo It consists of stone insulation bricks; the composite brick is a four-layer structure, which consists of calcium aluminate thermal facing bricks on the bottom layer, light mullite insulation bricks on the second and third layers, and hard calcium silicate board on the top layer. The raw material ratio of the calcium aluminate hot facing brick is shown in Table 2, and the raw material ratio of the synthetic calcium aluminate aggregate is shown in Table 1.

[0042] in:

[0043] Calcium aluminate cement includes the following chemical composition: Al 2 o 370%, CaO 25%, Fe 2 o 3 0.1%, SiO 2 4%.

[0044] The particle size of the calcium aluminate fine powder is 300 mesh; the particle size of th...

Embodiment 2

[0061] The calcium aluminate fully assembled tin bath roof brick for the float glass tin bath described in Example 2 is composed of a support brick and a combined brick, and the support brick is composed of a bottom calcium aluminate hot facing brick and an upper layer of lightweight Mo It consists of stone insulation bricks; the composite brick is a four-layer structure, which consists of calcium aluminate thermal facing bricks on the bottom layer, light mullite insulation bricks on the second and third layers, and hard calcium silicate board on the top layer. The raw material ratio of the calcium aluminate hot facing brick is shown in Table 2, and the raw material ratio of the synthetic calcium aluminate aggregate is shown in Table 1.

[0062] in:

[0063] Calcium aluminate cement includes the following chemical composition: Al 2 o 3 70%, CaO 25%, Fe 2 o 3 0.1%, SiO 2 4%.

[0064] The particle size of the calcium aluminate fine powder is 300 mesh; the particle size ...

Embodiment 3

[0081] The calcium aluminate fully assembled tin bath roof brick for the float glass tin bath described in Example 3 is composed of a supporting brick and a combined brick, and the supporting brick is composed of a bottom calcium aluminate hot facing brick and an upper layer of lightweight Mo It consists of stone insulation bricks; the composite brick is a four-layer structure, which consists of calcium aluminate thermal facing bricks on the bottom layer, light mullite insulation bricks on the second and third layers, and hard calcium silicate board on the top layer. The raw material ratio of the calcium aluminate hot facing brick is shown in Table 2, and the raw material ratio of the synthetic calcium aluminate aggregate is shown in Table 1.

[0082] in:

[0083] Calcium aluminate cement includes the following chemical composition: Al 2 o 3 70%, CaO 25%, Fe 2 o 3 0.1%, SiO 2 4%.

[0084] The particle size of the calcium aluminate fine powder is 300 mesh; the particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com