Sulphoaluminate cement clinker and preparation method thereof

A technology for sulfoaluminate cement and clinker, applied in the field of sulfoaluminate cement clinker, can solve problems such as the waste of aluminum resources and the environment, and achieve the effects of superior coagulation performance, readily available raw materials and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

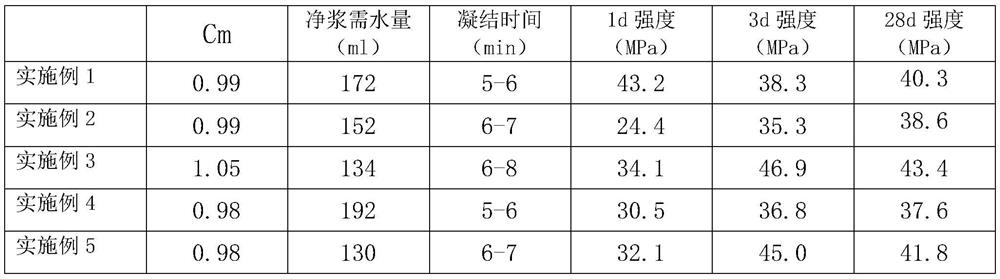

Examples

Embodiment 1

[0023] A kind of sulphoaluminate cement clinker, described sulphoaluminate cement clinker comprises the following raw material components in parts by weight: 30 parts of bauxite, 49 parts of socalcite, 16 parts of desulfurized gypsum, 5 parts of aluminum ash share.

[0024] See Table 1 for the main components by weight percentage of bauxite, socalcite, desulfurized gypsum and aluminum ash in Example 1.

[0025] Table 1

[0026] raw materials / ingredients loss SiO 2

al 2 o 3

Fe 2 o 3

CaO MgO SO 3

TiO 2

Bauxite 11.34 16.39 59.58 3.9 0.84 1.57 2.67 Calcium stone 42.55 1.78 0.84 0.36 53.2 1.15 Desulfurization gypsum 16.08 1.53 0.27 0.12 34.92 0.24 43.36 aluminum gray 1.83 73.77 3.34 6.4 3.87

[0027] The preparation method of above-mentioned sulphoaluminate cement clinker, the steps are as follows:

[0028] S1. Mixing bauxite, supercalcite, desulfurized gypsum and alumi...

Embodiment 2

[0033] A sulphoaluminate cement clinker, the sulphoaluminate cement clinker comprises the following raw material components in parts by weight: 29 parts of bauxite, 47 parts of socalcite, 10 parts of desulfurized gypsum, 8 parts of aluminum ash share.

[0034] The main components in weight percent of bauxite, socalcite, desulfurized gypsum and aluminum ash in Example 2 are the same as those in Example 1.

[0035] The preparation method of above-mentioned sulphoaluminate cement clinker, the steps are as follows:

[0036] S1. Mixing bauxite, supercalcite, desulfurized gypsum and aluminum ash, grinding and sieving to obtain mixed powder;

[0037] S2. Calcining and cooling the mixed powder to prepare the sulphoaluminate cement clinker.

[0038] In step S1, the sieving is through a 200-mesh sieve.

[0039] In step S2, the calcination is performed at 1000-1300° C. for 30 minutes, and then at 1300-1350° C. for 15 minutes.

Embodiment 3

[0041] A sulphoaluminate cement clinker, the sulphoaluminate cement clinker comprises the following raw material components in parts by weight: 24 parts of bauxite, 52 parts of socalcite, 16 parts of desulfurized gypsum, 8 parts of aluminum ash share.

[0042] The main components in weight percent of bauxite, socalcite, desulfurized gypsum, and aluminum ash in Example 3 are the same as those in Example 1.

[0043] The preparation method of above-mentioned sulphoaluminate cement clinker, the steps are as follows:

[0044] S1. Mixing bauxite, supercalcite, desulfurized gypsum and aluminum ash, grinding and sieving to obtain mixed powder;

[0045] S2. Calcining and cooling the mixed powder to prepare the sulphoaluminate cement clinker.

[0046] In step S1, the sieving is through a 200-mesh sieve.

[0047] In step S2, the calcination is performed at 1000-1300° C. for 30 minutes, and then at 1300-1350° C. for 15 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com