A kind of high flash point quaternized polyether block silicone oil and its preparation method

A technology of quaternized polyether block silicone oil, which is applied in the preparation of high flash point quaternized polyether block silicone oil, and in the field of high flash point quaternized polyether block silicone oil, can solve the problem of storage and use process. Potential safety hazards, increased production costs, potential safety hazards, etc., to achieve the effect of excellent synthesis effect, high safety, and good solubility

Active Publication Date: 2022-05-31

WACKER DYMATIC SILICONES SHUNDE CO LTD FOSHAN

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Literature (Zhang Qiang, An Qiufeng, Li Xiaolu, etc. Preparation and Application of Hydrophilic Polyether Amino Silicone QPEAS Silicone Emulsion [J]. Printing and Dyeing Auxiliaries, 2018(6).) Using terminal epoxy silicone oil and different molecular weight tertiary amines Polyether reaction can directly obtain quaternary ammonium polyether silicone oil, but this process uses a large amount of isopropanol solvent, which has a low flash point of only 12°C, and there are safety hazards in the process of production, transportation, storage and use, as well as environmental pollution. larger

Even if the isopropanol is removed by vacuum and then replaced with a high-flash point solvent, the safety risk can be reduced in the process of transportation, storage and use, but there are still safety hazards in the production process, and the replacement of the solvent will also increase the production cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Login to View More

Abstract

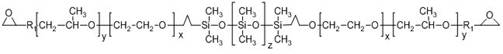

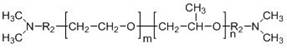

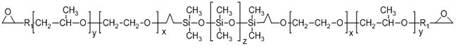

The invention provides a method for preparing high-flash point quaternized polyether block silicone oil, which uses epoxy polyether silicone oil and tertiary amine polyether as raw materials, and uses high-flash point alcohol solvents as solubilizers, which can replace low-flash point isotropic Propanol undergoes amination ring-opening reaction to obtain polyether polysiloxane copolymer silicone oil with terminal quaternary ammonium salt structure in one step. The high-flash point solubilizer is selected from alcohol / ether solvents with strong solvency. Its structure contains lipophilic alkyl segments and hydrophilic hydroxyl / ether segments, which can dissolve hydrophobic organosilicon compounds. It can also dissolve hydrophilic tertiary amine polyether.

Description

A kind of high flash point quaternized polyether block silicone oil and preparation method thereof technical field The present invention relates to the technical field of silicone oil synthesis, more specifically, relate to a kind of high flash point quaternized polyether block A preparation method of silicone oil and a high flash point quaternized polyether block silicone oil prepared by the method. Background technique Patent (US5807956) diepoxy polysiloxane and amine polyether can prepare block polyether silicone oil, compared with traditional The side chain amino silicone oil, the introduction of amino groups in the main chain can improve the hydrophilic properties of the fabric and maintain a certain degree of softness. can. On the other hand, the polyether segment can further obtain better hydrophilic properties. In order to introduce the quaternary ammonium salt structure, further High hydrophilic performance, the patent (WO2009115412) is modified with quate...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08G77/46

CPCC08G77/46

Inventor 林伟鸿黄强谢树明郭玉良

Owner WACKER DYMATIC SILICONES SHUNDE CO LTD FOSHAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com